The Warré hive was developed in France by a hereditary beekeeper who has devoted more than 50 years of his life to the maintenance of the apiary. Moreover, 25 of them he took honey bees exactly in the hives of his own design, considering them as close as possible to the natural habitat of these insects.

The content of the article

- 1 A bit of history

- 1.1 Varre’s philosophy

- 2 Design features and dimensions

- 2.1 Blueprints

- 3 Assembly recommendations

- 4 Features of beekeeping

- 4.1 Honeycomb brackets

- 4.2 Combating high humidity

A bit of history

The authorship of Emile Varre belongs to the wonderful manual “Beekeeping for All”, which has survived eleven reprints. The last issue of the book was made during the life of the abbot – in 1948 (Varre died in 1951).

This research beekeeper has tested more than ten hive systems in practice. There were 350 hives in his apiary, in which he carefully monitored the vital activity of bee colonies. The result of many years of experience was the rejection of frame beekeeping. The abbot developed his own bee house and began to use it without the usual honeycomb frames.

Varre’s philosophy

Emile Varré strove for natural beekeeping, which is based on minimal intervention in the life of bees. His hive system is exactly in line with this philosophy – insects bring nectar and process it into honey without requiring special care or supervision from the beekeeper.

In inventing his hive, Padre Emil was based on the following conclusions:

A good honey base is the basis for successful bee keeping. Any beekeeper knows about it. However, few people take into account that not everything here depends only on the bee colonies themselves. In agrarian developed countries, more honey plants will be planted, which will create favorable conditions for the operation of the traditional Dadan and Ruth hive systems. It was under such ideal conditions that these types of hives were created, which are readily used by beekeepers all over the world. And it is in such countries that any apiary will be profitable, subject to proper care of bee nests (the owner should not be overly active – interfere with natural processes).

The rich melliferous base allows you to keep many hives in a relatively small area. But what if the conditions are not so favorable for obtaining marketable honey? The beekeeper made a logical conclusion that the apiary needs to be enlarged several times and the bee houses should be distributed over several points. This is where Varre’s hives come in handy, requiring minimal maintenance! After all, frame structures take too much time from the owner of the apiary. With an increase in the size of the beekeeping farm, it is necessary to resort to the help of strangers. In addition, it is impossible to increase production in a number of regions – there is not enough melliferous base. That is, the hives need to be spread over a much larger area, which complicates their care. Or to engage in wandering, which is not profitable due to transport costs and for a number of other reasons (lack of time affects, for example).

By changing the approach to beekeeping, you can achieve profitability in all climates and even with a small honey base. The bees will be able to live independently, generating income for the owner. And this is not surprising! After all, these insects lived autonomously for thousands of years before they were domesticated by humans.

Rejection of the frame allows you to achieve a minimum cost of the final product. The beekeeping economy is organized with maximum rationality – it grows, is distributed over a large territory and exists almost autonomously.

Varre believed that the frame is the lot of amateurs, inclined to communicate with nature and not interested in the production of large volumes of honey. Apiaries with frame hives allow the owners to earn a little extra money, actively spending time in the fresh air. And frameless beekeeping brings the economy to a professional level with maximum income.

Padre believed that saving money on investment was much more important than maximizing the performance of each hive. And the profit made is more important than income.

That is, the low cost of honey will only be:

- at low labor costs;

- while saving time;

- at a low price of the hives themselves.

Design features and dimensions

The beehive of Abbot Varre was once called La ruche populaire – the people’s beehive. The design allowed people of both sexes and at any age to engage in beekeeping!

Compact housings filled with honey weigh about 12-15 kilograms. It is within the power of not only men to lift them, but also boys, women, and the elderly.

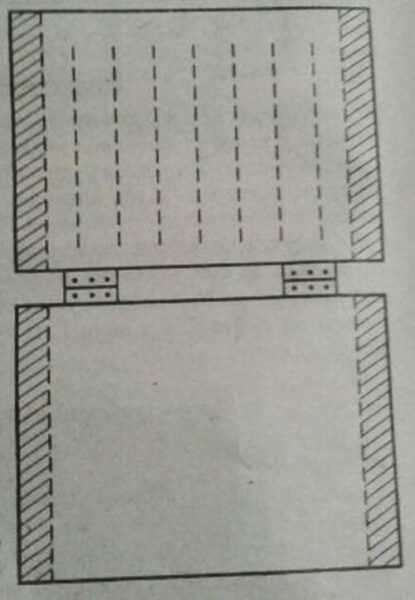

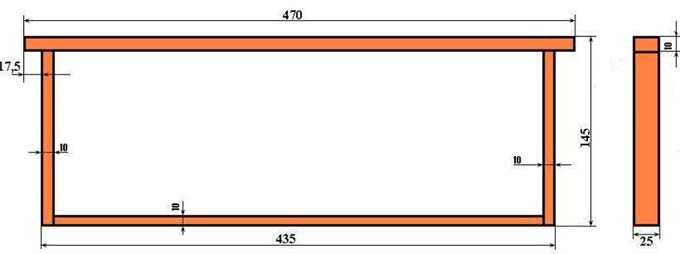

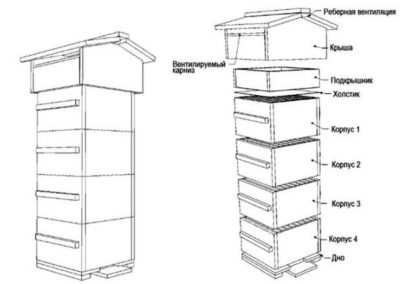

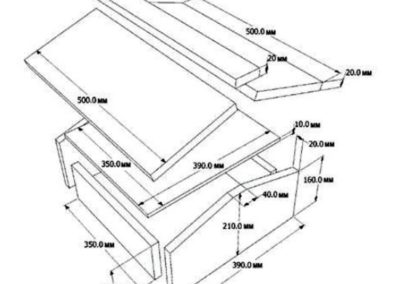

The base of the hive is vertical sections. They have a square section of 300 by 300 millimeters and a small height of 210 mm. Rulers with glued strips of wax are inserted inside, prompting the bees in which direction to rebuild the honeycomb. Construction inside the hive takes place as in a tree hollow – from top to bottom.

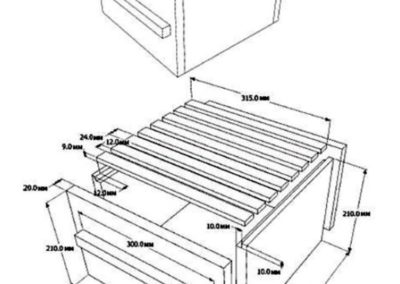

In total, eight rulers with 315 mm length, 24 mm width and 9 mm thickness need to be installed on the body section. They fit into the grooves of each case, like the upper bars of ordinary honeycomb frames. The distance between the rulers is 36 mm (from the center of one to the middle of the other).

Wax strips or fillings are not traditional foundation! Although it can be used too. They are installed at the bottom of the rulers. And they have a width of 0,5 to 1 cm.

It is noteworthy that frames can be hung in such cases! Actually, the initial version of the hive was designed specifically for frames with dimensions of 300 width and 180 mm height.

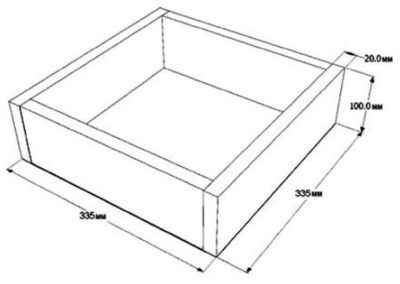

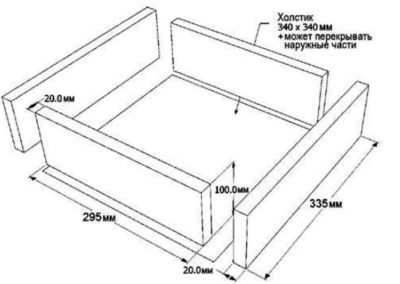

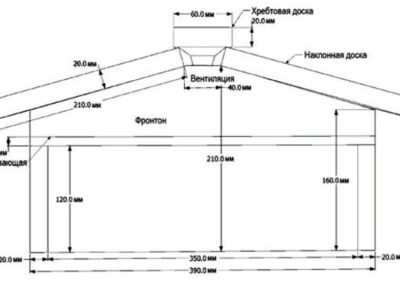

In the upper case, a lap is spread over the rulers. A roof cover is installed on top, insulated for the winter with natural material – a pillow with hay, sawdust, straw, dry foliage. The height of the roof liner is 100 mm, the internal dimensions are the same as those of the housings.

The design of the lid is interesting. It is gable with a ventilated attic, tightly separated from the main hive space by boards, which excludes the entry of rodents here.

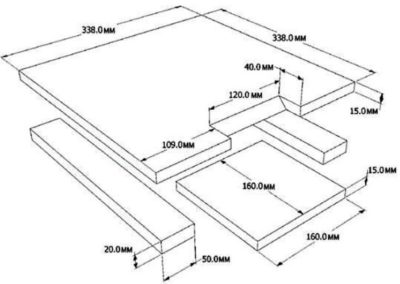

A stand with a 120 mm wide taphole and a board for the arrival of bees is used as the bottom.

Blueprints

Hive Warre Blueprints:

All the above drawings belong to the Abbot Varre himself – taken from his book and translated into Russian.

Assembly recommendations

For assembly it is recommended to use boards with a thickness of 20 to 50-60 mm. In this case, the internal dimensions remain unchanged!

Note: Varre practiced 20mm and 24mm board assembly. This thickness was quite enough for the climatic conditions of France. In Russia, the walls must be made thicker.

The body parts are joined by a direct connection, which simplifies their production. For convenience, handles are stuffed from the outside of bars with a section of 20 by 20 mm. Handle length 300 mm. The upper plane of the bars can be made slightly beveled to drain rainwater. They are fastened with nails of a suitable size (three pieces on both sides of the body).

If it is not planned to put an insulating pillow into the under-roof, a thick natural fabric must be nailed along its bottom that can hold bulk insulating material.

For the manufacture of the cover, you can take boards with a thickness of 20 mm or thinner lumber. The edge of the lid is located below the sub-roof, preventing moisture from entering the interior of the house.

The bottom is assembled from boards 15-20 mm thick. Its dimensions are 2 centimeters smaller along the entire perimeter than the dimensions of the case. This is a protective measure against dripping water droplets from above.

Features of beekeeping

Bees hibernate in two hull sections containing at least 12-13 kilograms of honey.

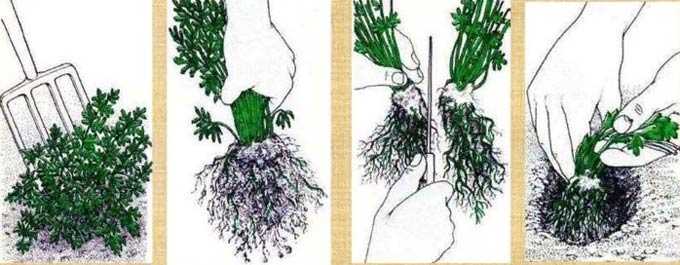

With the onset of spring heat, the nests are expanded – the hulls are raised, and one or two more sections are introduced from below. At the same time, rulers with guiding wax strips are installed in each of the new cases!

During a bribe, the body sections are also substituted from below. At the end of the honey collection, remove the upper sections filled with mature honey.

Honey is extracted from the honeycomb using a centrifuge, after placing it in special nets. Or they open the cells and wait for its natural drainage

Please note: The honeycombs in the hive are not monolithic – they break off in each body section, not reaching the upper edge of the lower rulers by about 4-5 mm. This is one of the main differences from the Japanese hive. In total, 9 hundred are being rebuilt (in the “Japanese” there are seven of them).

To read:

Japanese beehive

Honeycomb brackets

When rebuilding honeycombs, bees must fix them at the top, which presents some inconvenience for the beekeeper – when extracting honey, the attachment points to the walls must be cut off. By its structure, the honeycomb is quite fragile. They break easily under the fingers and some of the honey flows out.

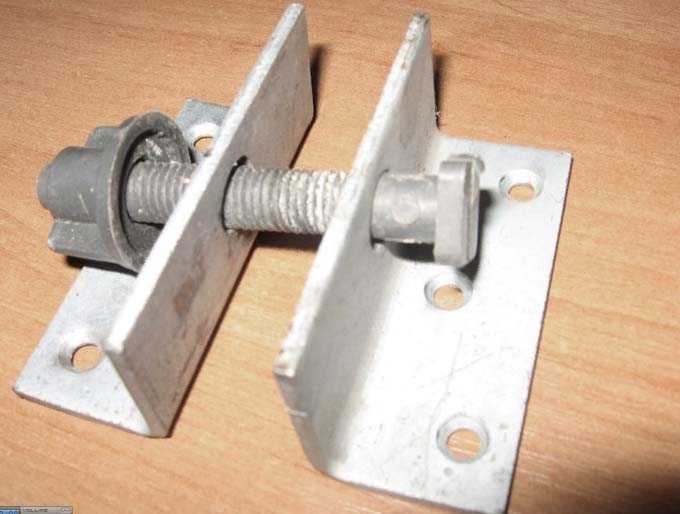

This problem can be solved by using porte-rayons or “honeycomb holders (brackets)”. The invention was patented by the Frenchman Gilles Denis.

The brackets are protrusions along both edges of each of the rulers, which are 90 mm long. Bees attach honeycombs to them, starting their construction from a guide strip of wax. The French call them “half frames”. They are used, among other things, for hatching queens and other manipulations with brood.

Combating high humidity

Dampness in bee nests is one of the reasons for the spread of varroa mites and other diseases. And hives assembled according to Varre’s drawings have one serious drawback – mold can form in them.

The humidity in bee houses is greatly influenced by the climate with cold winters, which is typical for Russia.

To avoid high humidity it is necessary:

- instead of a canvas for the winter, install a deaf ceiling, and place the lap between it and the roof liner, in order to avoid propolisation of the gap between these structural details;

- make a removable airplane board that will be removed for the winter – in this case, the snow will not block the ventilation;

- in regions with a harsh climate, make walls at least 6 cm thick in order to even out temperature drops;

- in each tier, drill small entrances to all sides of the world with a diameter of 15 mm, and close the bottom gap completely – the bees will orient themselves with the direction of the prevailing winds and the state of the microclimate inside the house, and then plug the extra holes with propolis;

- if additional entrances are drilled in the hulls, remove the bottom and instead install a box similar to an under-roof, but with a blind bottom and without a tap-hole – there should be a window with a hinged door in the back for extracting dead water and debris in the spring;

- use only hardwoods, which are warmer and dry faster than pine or spruce.

The Warre hive is a design designed to meet the natural needs of honey bees. It is ideal for beekeepers who focus on sustainable honey production. Beekeepers using framework systems will find it more difficult to experiment – they are accustomed to a different work organization. True, it is possible to evaluate the construction of Abbot Warré even from one beehive installed on a point.