The design of this multi-hull bee dwelling is striking in its compactness – the Boa hive, proposed by Vladimir Davydov, is disassembled into small in size and light in weight hive. It is the weight and dimensions that are of decisive importance for many beekeepers when choosing the type of hive for their apiary.

The boa constrictor is not the most common construction among domestic beekeepers. However, such a dwelling can be made by hand, like any other more popular type of bee hives.

The content of the article

- 1 Structural features

- 1.1 Advantages

- 1.2 Possible disadvantages

- 2 Dimensions and Drawings

- 2.1 Framework

- 2.2 Selection of drawings

- 3 Features of keeping bees

- 3.1 Beehive boa constrictor beekeeping

- 4 Beehive boa constrictor hatching

Structural features

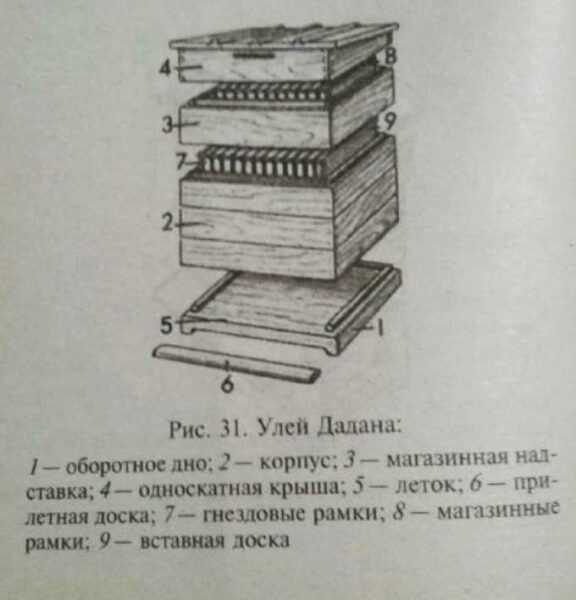

The multi-housing house from Vladimir Davydov belongs to the small-format type – it accommodates a honeycomb frame, which is a quarter less than the most common Dadanov one. That is, the size 280 x 110 is used here, instead of the usual 435 x 300 millimeters.

Accordingly, when nasching, the standard foundation has to be cut into four equal parts and only then inserted into the boa frame.

The small dimensions of the main building element of the hive make it possible to eliminate the use of wire. The foundation is simply inserted into the special cut made on the upper bar. It is extremely convenient – practicing beekeepers know how much effort and time it takes to pull the wire and wax in the classic way.

In addition, the wire sags during operation, and if it is inaccurate and improperly pulled, it damages soft wood, leading to damage to the honeycomb frames.

You can verify the complexity of the process yourself by reading the relevant articles on our website:

How to impose frames – using effective homemade products

We pull the wire correctly – homemade products for working with frames

Each body section of the hive accommodates 9 small honeycomb frames. When filled with honey, the body weight reaches an average of 12-13 kilograms.

The house is well ventilated thanks to the ventilation hole located in the center of the ceiling and tap holes in all buildings. And the fight against ticks is facilitated by the basement space, equipped with a pull-out tray – here you can install an anti-tick net.

Advantages

The advantages of this type of hive include:

- low weight of body sections;

- small area of honeycomb frames – bees master them faster even with small bribes in nature;

- there is no need to use warming pillows – a comfortable microclimate is easily established in the house (realizing this, the author of the idea deliberately abandoned the roof cover);

- there is no need for cores – queens can be removed directly in the main hive;

- the presence of a lower tray facilitates the removal of dead bees in the spring and ticks during treatment with acaricidal preparations.

There are no problems during the bribe period with the hive. The body sections can be easily removed and carried to the pumping point. And in each holder of the honey extractor, two honeycomb frames are placed at once.

The absence of wire allows you to sell high-quality comb honey – it has a marketable appearance, is well cut into pieces. Fresh foundation is installed in a matter of seconds – it is enough to thread a quarter of a sheet through the slot in the top bar. There is no foundation waste.

The interchangeability of all structural elements is also important – the beekeeper can freely operate with frames and bodies, without thinking about the size. At the same time, the help of a partner is not required – each section weighs little and can be easily moved, carried, rearranged together with honeycomb frames.

Possible disadvantages

The disadvantages of the design can be attributed, rather, to the peculiarities of keeping bees in the Boas, rather than to serious shortcomings.

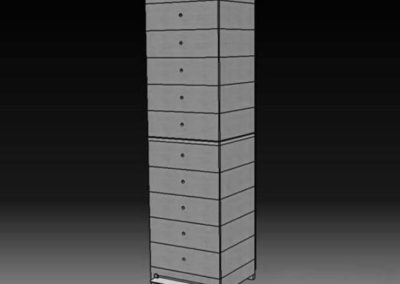

The hives are unstable due to their high height – they are assembled from 8-10 hulls, but at the same time they take up little space on the transport platform for migrating and in the winter house.

A nest for the winter is formed not in one or two buildings, but in four or five. This is the specificity of beekeeping in Boa, which will take some getting used to.

When assembling the hive, you need to tinker with a lot of details, since there will be really a lot of cases, unlike the same Dadans. However, this does not require knocking down and gluing the shields for the walls, which can be safely attributed to the advantages of this model.

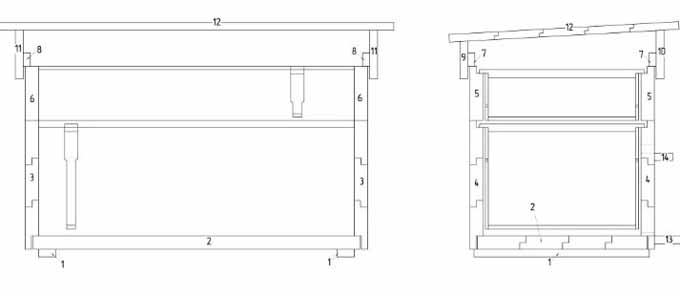

Dimensions and Drawings

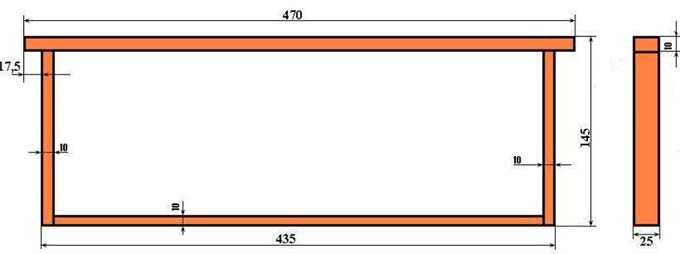

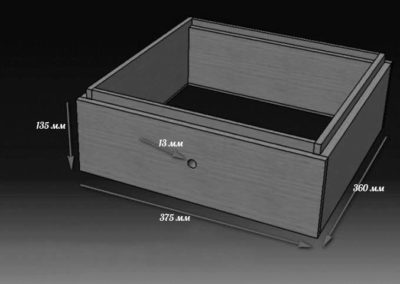

The dimensions of the boa constrictor hive are as follows (in mm):

- front and side walls – 375 lengths, 135 heights, 30 thicknesses;

- sidewalls – 340 lengths, 135 heights, 30 thicknesses;

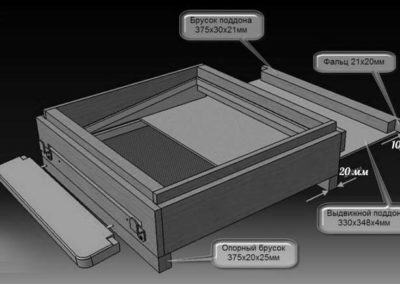

- bottom: front and rear harness 375 length, 90 height, 30 thickness; side piece of strapping 340 lengths, 90 heights, 30 thicknesses;

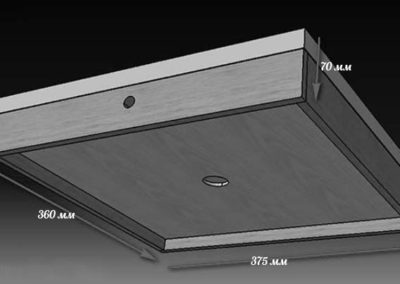

- finished cover – 375 x 360 x 70 mm height;

- cover sides – 342 lengths, 65 heights, 20 thicknesses.

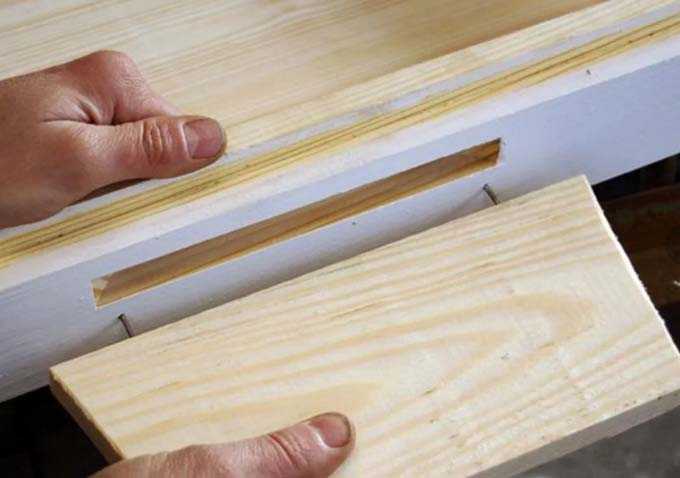

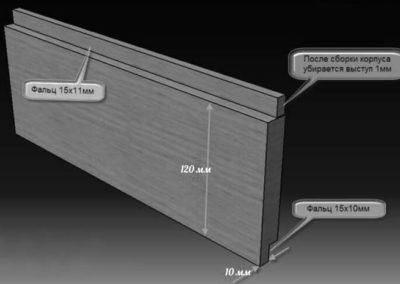

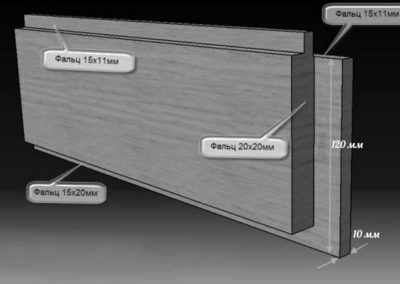

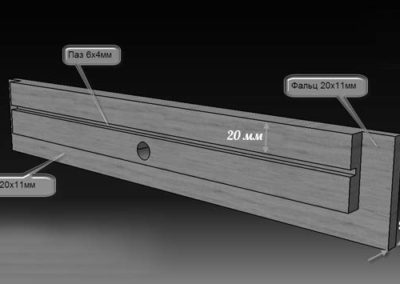

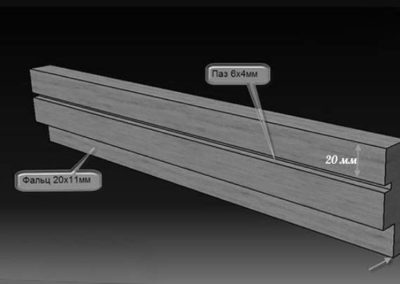

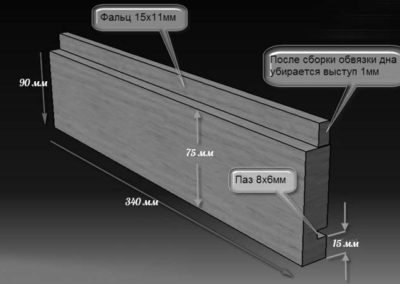

The main difficulty during assembly is the presence of multiple grooves and folds. For example, on the back (front) wall of the hull sections, you need to make four selections:

- from the bottom inside – 15 by 20 mm (for installing the section);

- at the top outside – 15 by 11 mm (also for firm positioning of the body when assembling the hive);

- on the sides – 20 by 20 mm (groove for mounting housing parts);

- top inside – 15 by 11 mm (shelf for installing honeycomb frames).

On the sidewall of the case, an outer fold is made at the top with a size of 15 by 11 mm and an inner fold at the bottom – 15 by 10 mm.

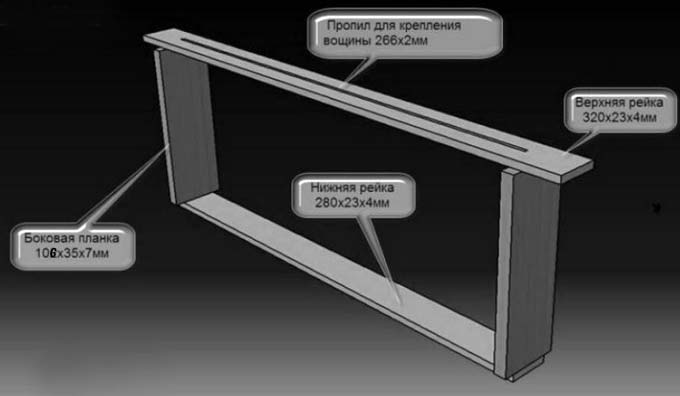

Framework

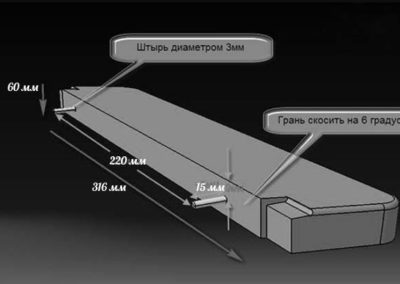

For the manufacture of honeycomb frames, the bars are blooming. Workpieces are cut from the rails obtained. Their dimensions (in mm):

- rail at the bottom of the sotoramka – 280 by 23 by 4;

- sidewalls – 106 by 35 by 7;

- rail at the top – 320 by 23 by 4;

- cut the top lath – 266 lengths, 2 widths.

In finished form, we get the Udav standard – 280 by 110 millimeters.

Selection of drawings

Beehive boa constrictor with your own hands – see drawings in the gallery below:

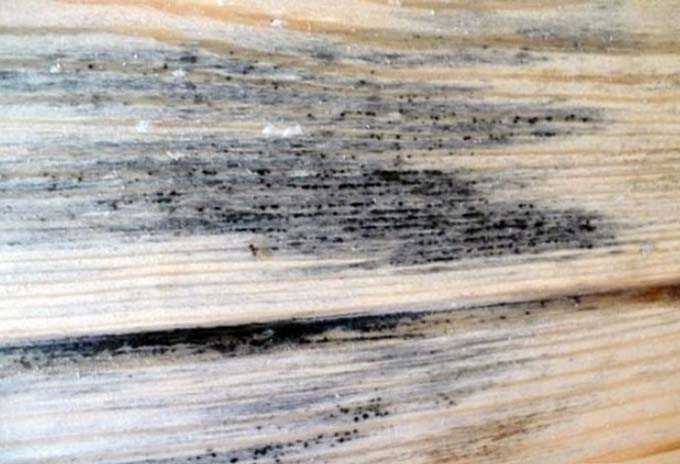

For manufacturing, dried boards with a thickness of 35 to 40 millimeters are used. The assembly is done in a quarter. The joints are additionally fastened with self-tapping screws.

The video below describes in detail the manufacture of body walls:

And also a selection of folds and quarters:

In the front wall of each hull section, a tap hole with a diameter of 13 mm is drilled. Handles are cut out on the sidewalls for easy portability and work with the hive.

Combined bottom. Its back wall slides out together with a plywood tray. A mesh insert is inserted at an angle through the tap hole. The entrance is 335 mm wide. The movement of the liner is carried out due to the grooves made on the side bars of the strapping.

Detailed manufacturing of the bottom is discussed in the video review:

The cover has an interesting design solution in the form of a central ventilation hole and a round taphole in the front wall of the harness. If necessary, the tap hole, which has a diameter of 13 mm (as in all cases), is closed with a plug.

This element of the hive is assembled according to the panel principle – there is a gap between the upper and lower sheet (ceiling), into which a heat-insulating material is installed, for example, a piece of foam with a size of 335 by 318 millimeters. The insulation is pressed against the ceiling – plywood inserted into the grooves of the strapping bars.

The manufacturing technology of this element is discussed in detail in the video:

Features of keeping bees

For the Boas, the classic technology of keeping in multi-housing dwellings is used, but taking into account the peculiarities of their design.

This hive has one important feature – when rearranging small-sized bodies, its nest does not have time to cool down even in cool spring weather.

Beehive boa constrictor beekeeping

As noted above, wintering is carried out in 4-5 hull sections. In the spring, the pull-out tray of the bottom is removed and cleaned of accumulated debris, dead bees. You can also replace it with a clean one, postponing the disinfection of the dirty bottom for a more convenient time.

Then the condition of the nest is assessed – its potential in the form of brood, the health of the bees, and the availability of sufficient food. Usually, the two lower sections are removed, which are already empty before the onset of stable heat.

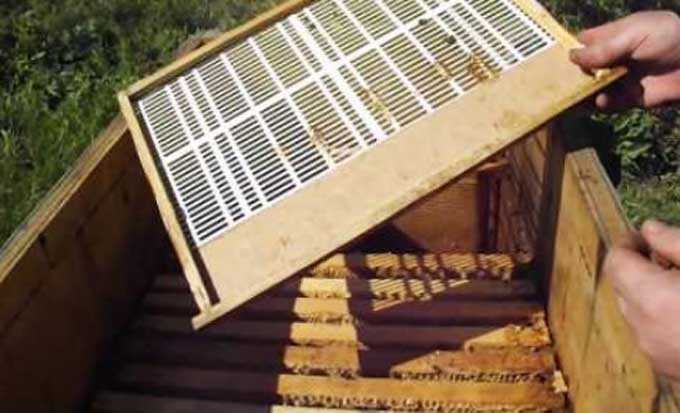

The first expansion is performed 7-10 days after the fly-by – a body section, complete with foundation, is installed against the nest. A dividing grid is placed under it. By this time, the first bribe should appear in nature. Then they follow the traditional expansion scheme – rearranging the buildings exactly like in other multi-housing houses.

You can read more about this technology here:

Multihull hives – the secrets of keeping bees

Expansion is always carried out ahead of the development of the strength of the bee colonies – so that there is a reserve in the volume of the house. This technique helps to avoid the emergence of the swarm instinct.

In the process of honey collection, empty or bee-filled hull sections are removed from the bottom. Ripe honey is selected from above. For wintering, pets are left in the lower sections of 6-8 kilograms of high-quality sealed honey (this is the volume of two buildings).

Beehive boa constrictor hatching

The small size of the honeycomb frames and the multi-body design facilitates the hatching of queens in the Boas

For this, a bottom cover is used, which has the dimensions of a conventional body section, but reduced in height. Plywood is installed here as the bottom, and a tap hole is made in the harness, to which a board for the arrival of insects is attached.

Note: If you make a window in the center of the plywood sheet and pick it up with a metal mesh, the bottom cover will allow you to connect two bee colonies without any problems. After the bees get the same odor, the separator is removed – a painless union takes place.

Sequence of work:

- The body is divided in half. Each of the compartments is equipped with two honeycomb frames with a closed brood and a fistulous brood (or unsealed brood), as well as one feeding frame with honey. You can substitute one foundation, so that later you will not be mistaken with the time of its installation – less effort will be spent on tracking, it will be easier to prepare for a transplant.

- A lid-bottom is placed on top and the same operation is repeated for the next body – dividing in half, issuing brood, mother liquor.

- You can get up to 8 “queens” (two per body) from one hive. In this case, the tap holes of each section are rotated 90 degrees – they are directed in all directions of the world.

- After the queens are hatched, the resulting families can be planted in new hives, or combined into one – it all depends on the tasks set by the beekeeper.

The advantage of the Boa Constrictor is that it avoids the use of core beehives. For comparison, in Dadans the same method of withdrawing “queens” is not applicable due to the small number of bees involved in the process.

In conclusion, I would like to note that the Boas are an ideal choice for those beekeepers who value, above all, the compactness of the houses and the low weight of individual structural elements. With regard to productivity, an average of 50-60 kilograms of marketable honey is obtained from one bee colony. In our opinion, these are rather modest figures for amateur apiaries.