Frame beekeeping replaced frameless bee keeping in the middle of the XNUMXth century. Prior to that, the main working unit of any apiary was a log hive – a “domesticated” tree hollow that served as a habitat for wild bees.

The content of the article

- 1 A bit of history

- 2 Deck and modern beekeeping

- 3 Log beekeeping and its principles

- 3.1 Advantages and disadvantages

- 4 Structural varieties

- 5 Frames in the deck

- 6 Collapsible design

- 6.1 Assembly

A bit of history

There is not a single historical synonym for the word “deck” when applied to an apiary. So, a hive in a block of wood in Russia was called “bort”, “duplyanka”, “duplyak”, “one-tree hive”. By this term, beekeepers defined the trunks of living trees, specially hollowed out under a hollow and inhabited by swarms.

Small portable beehives were called “small beehives” – decks, bodies, dugouts with honey and foundation, which were tied to tree trunks as bait for wandering swarms.

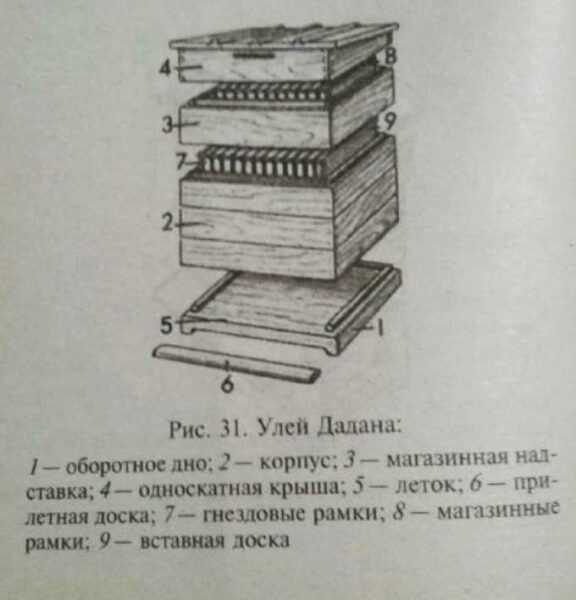

That is, a beehive is a primitive bee hive in a hollow of a tree or in a block, a block, devoid of the frames familiar to a modern beekeeper. This is the design with which the Russian frameless beekeeping began, in the future giving way to modern hives such as Dadan or multi-hull Ruth.

To some extent, Japanese beehives and houses constructed by the French Abbot Varre can be considered analogs of the Russian log deck. The development of beekeeping in different regions of the world followed almost the same path – domesticated bees were settled in housing that most closely resembled the natural habitat in the forest.

Read more on this topic:

Japanese hives – construction and other features

Abbot Emile Warré and his frameless hives

Deck and modern beekeeping

Whether or not to choose a deck as a beehive for organic beekeeping is up to the apiary owners. But before making this decision, it would be nice to answer a simple question – what is an apiary for?

There can be only three answers here:

- The person starts a profitable business. Everything in his farm must meet modern standards – this is the basis for the production of commercial honey on an industrial scale.

- The owner decided to get closer to nature and get some sweet treats at the same time. In this case, only surplus honey, if any, will appear on the farm.

- A beginner needs honey exclusively for himself, his family, relatives and guests. He is not going to sell it. This option represents a cross between an industrial and an organic (eco-) apiary.

The deck is only suitable for small hobbyist bee farms, as shown in the last two examples. And then, if the beekeeper does not secretly dream of earning money in his backyard apiary! In this case, loungers will be useful – the most “lazy” hive systems that do not require a special application of physical forces, or houses assembled according to the Dadan-Blatt design.

Industrial production is based on the operation of multi-body Langstroth-Root systems, which can bring maximum profit, but require additional manpower.

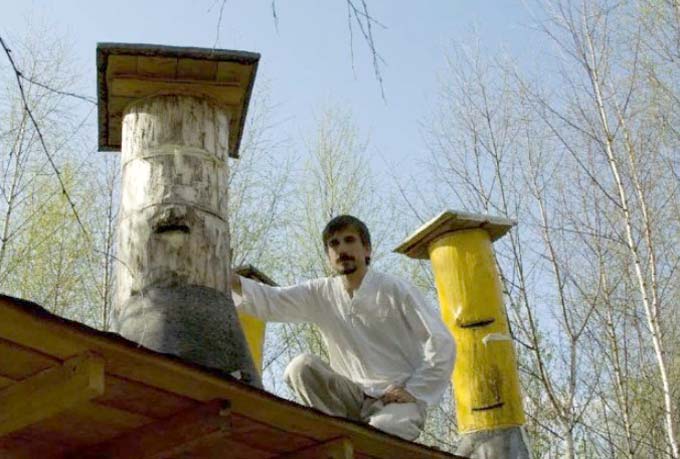

This is how the decks used by the Larionov family look like:

Such hives do not take up useful space – they are placed on the roof. Does not require human intervention. And the owners cost a penny.

Log beekeeping and its principles

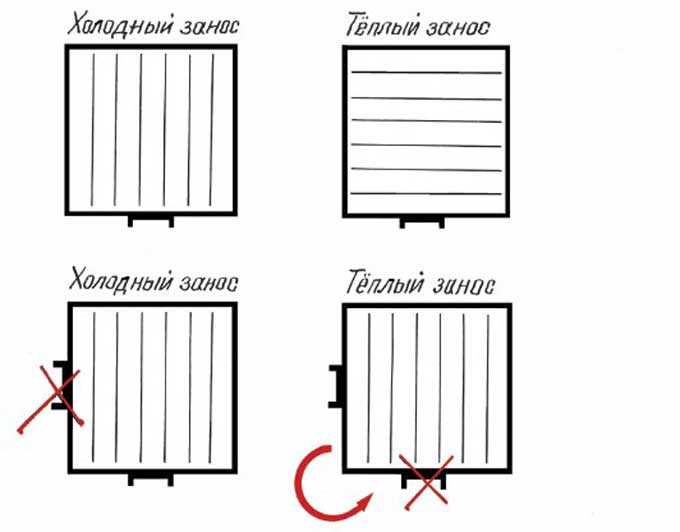

The philosophy of beekeepers, based on the principles of ancient Russian beekeeping, is based on non-interference in the life of bee colonies.

And this means:

- lack of frames with stretched wire and foundation;

- the installation of a wooden cross-piece in the dwelling (the same principle of arrangement for Japanese hives and, with minor features, for Varre’s hives);

- non-interference in the life of the nest until the moment the honey is pumped out – the bees themselves build honeycombs, regulate the amount of brood, collect nectar;

- providing pets with a large deck, with a margin for the development of the bee colony.

Andrey Yakimov, relying on these principles, has developed his Vladimir lounger for 32 frames. The author believes that it is as close as possible to the structure of the deck, although it is equipped with frames for the convenience of the beekeeper’s work.

Read on the topic:

Vladimirsky lounger

Advantages and disadvantages

With all the naturalness of log beekeeping, this technology has its drawbacks:

- obtaining honey in sufficient quantities is possible only for 2-3 years of family maintenance;

- weak nests winter poorly, not having time to gain strength before the onset of cold weather;

- it is difficult to fight infections and parasites in hives;

- insects can live in one deck for a maximum of five years – then the beekeeper will have to remove the pets and general cleaning in the house;

- in the summer heat, the honeycomb inside the dwelling can break off – bees die, the harvest is lost;

- it is difficult to select honey – you need an assistant and good protection from attack, since insects behave more aggressively than in ordinary frame hives;

- the quality of the commercial product will be average, because the bees deposit nectar in the same cells where the brood was previously (which is clearly visible on thematic videos).

We have already mentioned the advantages of decks. This is ease of maintenance, low cost of houses, significant savings on artificial foundation and frames.

Structural varieties

It is quite simple to assemble a hive log with your own hands – I hollowed out a dry tree trunk, drilled a hole just above its center, equipped a lid – and this is where the work is completed. The Russian beekeepers acted exactly according to this algorithm.

Having populated the swarm, they waited for the completion of the honey collection, destroyed the pets and took all the honey for themselves. Such beekeeping is far from the modern principles of an organic apiary, based on a humane attitude towards bees.

It is, of course, possible to understand our ancestors. They did not know exactly how the bee colony lives. And the construction of the decks itself was not very convenient – it was extremely difficult and dangerous to extract honey, because the bees fiercely attacked the violator of their borders.

Nowadays, the equipment of the beekeeper has become better, and the design of the old board has been noticeably improved.

There are two designs that are quite suitable for an eco-apiary. It:

- a deck equipped with frames … in spite of all the requirements of frameless beekeeping;

- and a collapsible deck, arranged according to the principle of a multi-body hive.

We will consider their manufacture with our own hands in more detail.

Frames in the deck

The use of honeycomb frames in log beekeeping was typical for the beginning of the XNUMXth century. This period was transitional – beekeepers abandoned the traditional border in favor of frame structures.

Such a hive is assembled as follows:

- A poplar or pussy willow with the thickest trunk is chosen. The tree falls down and a workpiece 1,5-2 meters long is cut from it (flat part of the trunk).

- After high-quality drying, the log is dissolved in half along the length on the sawmill. The core is selected from the inside. Both parts of the log are fastened with screws.

- Under the ceiling, honeycomb frames are installed in one row – from 5 to 10 pieces, depending on the thickness of the trunk. There will be a brood zone – the holy of holies of the hive, in which the beekeeper intervenes only when absolutely necessary (for example, he changes the queen or old combs in the spring). In the same part of the log, bees accumulate food reserves for the winter.

- Above the nest, insulation is carried out and a cover is installed from trimming a log – a circle 20-30 cm thick.

- In the back of the hive, two hinged doors are made – through the upper one you can inspect the nest, and through the lower one take honeycomb frames with ripe marketable honey. A similar idea was implemented in the hives invented by the Ukrainian beekeeper Prokopovich.

A variant of the same model is a construction of vertically installed boards 40-50 mm thick, fastened with iron hoops (like a barrel). There is a removable bottom and a lid equipped with a bar handle for ease of use. Inside, crosses or frames are installed – at the discretion of the beekeeper.

Such systems are inconvenient to transport. And, of course, it is impossible to control the state of the bee colonies, as in any other deck.

Collapsible design

The following model has much in common with the developments of I.S. Kullandy and V.F. Shapkin.

For work you will need:

- angle grinder;

- hand tools, including axes;

- electric drill and plane;

- milling cutter;

- chainsaw with tire attachment.

The nozzle is made independently from a square pipe with a cross section of 25 by 25 mm. To fix it in a 50 cm long bus, two 8 mm holes are made:

- the first 35 cm from the toe;

- the second is 10 cm from the first hole.

The nozzle itself is welded from nine pieces of a square pipe 15 cm long and one 12 cm long.On a short segment and the two nearest to it, two 8-mm bolt holes are made (the distance between the fasteners is 10 cm). And to the seventh segment, counting from the tire, a handle from an angle grinder is screwed.

Together with the saw, the attachment rests on a 60 cm high stand made of 20 mm pipe. The support is welded to a 10 mm thick plate having several holes with a diameter of 4-5 mm around the circumference.

During the processing of workpieces from the outside, the support is attached through the plate with self-tapping screws to the end of the block.

And this is how a device with a similar design works. In the video, a Chinese craftsman uses a movable support mount in the deck using a hole drilled in the workpiece – and processes the body section from the inside in a matter of minutes:

A simpler, but laborious way is to dissolve the blanks into two parts and hollow out the core by hand using an ax, and then assemble the body parts with self-tapping screws and clamp them with metal rims.

Assembly

For manufacturing, dry, not rotting wood is taken – willow, aspen, linden with a trunk thickness of 45-50 cm. Suitable for a windbreak.

The inner diameter of the hive should be between 22 and 35 centimeters. The wall thickness is approximately 70-80 mm, which will smooth out daily temperature fluctuations. The height of each vertical section is 30-33 cm.

Bees hibernate in two rounded enclosures, as Varre advised. One such case can hold up to 12 kilograms of honey – this is the standard for any small-format hive, for example, an Alpine or Boa.

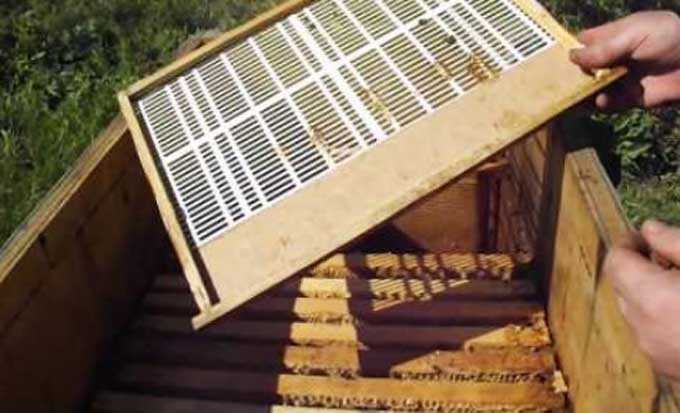

In each case, circular folds measuring 12 by 12 mm are hollowed out from the inside along the upper cut. They serve as a support for the guide rulers at the top – here they put 6-7 pieces of slats with a section of 10 by 10 mm, on which strips of wax are attached. In the lower sections, the crosses rest on the folds.

One rail is installed perpendicular to all the entrances. For this, holes of a suitable diameter are drilled in the walls. A rail is introduced into them – its ends by 1,2-1,5 cm will protrude from the outside.

All of the listed honeycomb holders are easily removed from the housings for cleaning and disinfection.

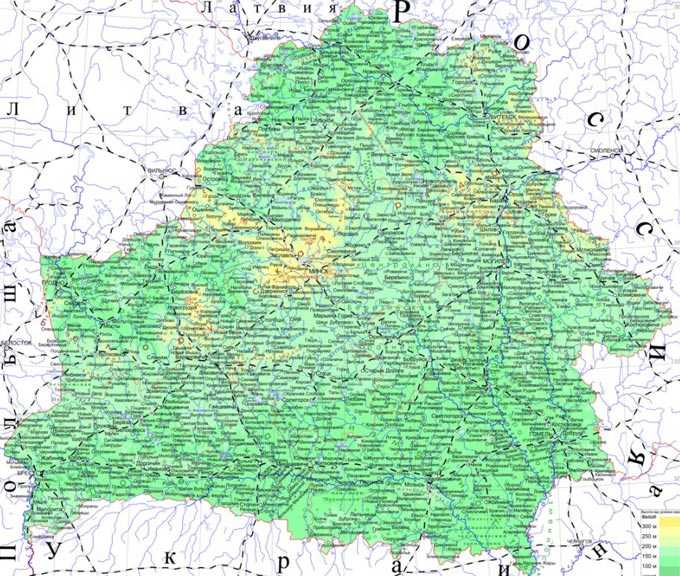

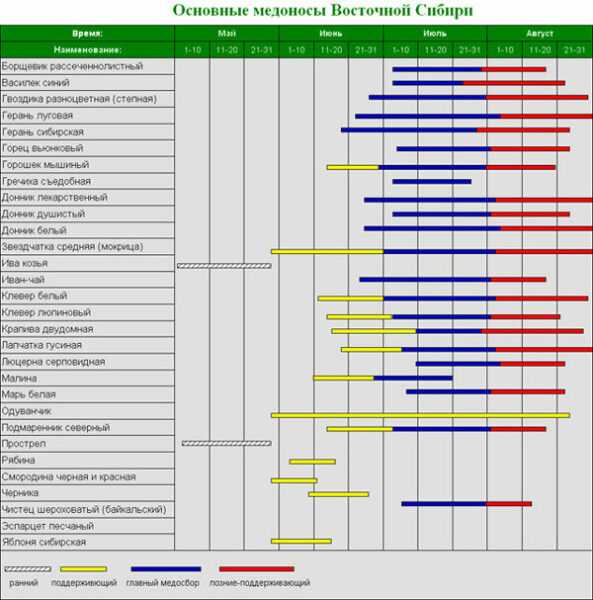

The number of body sections is selected based on the honey base of a particular region. For example, two hulls are enough to land one large swarm.

The holes are drilled in each body section and have a diameter of 30 mm. Unused holes must be plugged with a self-tapping stopper (screwed in from the side and does not allow the plug to fall inside). The arrival shelf is selected from the outside with an angle grinder – a 125 mm disc is used.

As a cover, a cone made of galvanized sheet is used, pressed onto the headrest. But it is inconvenient when hanging the hive in the trees – for such conditions a flat “cork” (a cut from the same log) is best suited – a headband without a pointed cover.

In order for the cover and headgear to stand steadily, they are additionally fixed on the upper body using punched tape and self-tapping screws. A canvas made of natural fabric is spread under the cover over the guide rulers.

Formwork plywood with a thickness of 20 mm and a size of 440 x 440 mm plays the role of the bottom. The hatch in it is cut out with a jigsaw along the diameter of the hive, and then the part is covered with a layer of drying oil and painted. The bottom is attached to the door hinge, and closed with a latch.

Family inspection is carried out from below through the hinged bottom. To realize this, it is necessary to weld a support from a metal profile or pipes. The top of the stand is a table top with a hatch mounted on a frame with dimensions of 450 x 450 mm. The height of the legs is 50-60 cm.

If you use thin fittings, the stand will vibrate from the wind and the touch of the beekeeper! Therefore, for reinforcement, corners are used, welded diagonally from all four sides.

The stand can be replaced with a corner support, with which the hive is suspended from a tree. The support is bolted to the bottom frame, and to the tree using self-tapping screws with a diameter of 8 mm or more.

It is noteworthy that you can choose a deck only from the inside, leaving the bark outside. The appearance of such beehives smells of antiquity – they look spectacular and unusual. And inside there will be a comfortable dwelling with the same diameter of all collapsible elements.