If the beekeeper has carpentry skills or is ready to learn how to do it, you can make a beehive with your own hands in your home workshop. Self-assembly will save on investments in the apiary and will give you the opportunity to experiment with the chosen design.

A striking example of such a useful modernization is the increase in the size of the body in horned hives up to 10-12 frames. This is done when there are abundant bribes in the region.

The content of the article

- 1 Basic requirements

- 2 Materials

- 3 Types of bee houses

- 3.1 Most popular models

- 4 Structural features

- 5 Tools and equipment

Basic requirements

To make a do-it-yourself bee hive, you need to take into account the basic requirements:

- the dwelling should be simple in design and convenient to work with;

- reliable protection of insects from dampness, heat and cold must be provided;

- proper ventilation is required;

- in the volume of the hive, the development of the nest (its spacious placement) is taken into account.

As far as construction is concerned, any popular model is suitable. However, when choosing a type of hive, it is better to be guided by the experience of local beekeepers who know well what is best for a particular region and breed of bees.

Materials

Despite the introduction of various modern materials, such as polystyrene, into the beekeeping industry, softwood is still considered the best choice for bee housing.

Tree – environmentally friendly and absolutely safe material with good performance characteristics. It is as close as possible to the natural habitat of bees.

For manufacturing, dry lumber is taken with a moisture content of no more than 15-16 percent. Fir, linden, aspen, pine, spruce and cedar boards have sufficient strength and at the same time softness in processing.

The most expensive materials are linden and aspen. Conifers will be cheaper for the owners, but it is necessary to monitor the quality of drying – fresh boards emit a lot of resin and this adversely affects the bees.

After assembly, the houses are varnished, putty, and then painted with light-colored paint.

You can read:

How to properly color bee hives

Choosing a paint color for a bee hive

Plywood Is another popular type of wood-based materials. It is quite durable and lightweight. However, it does not provide optimal thermal insulation for wintering – and this is an important point. Afraid of precipitation.

Ideal for assembling the inner housings of double-walled models such as Cebro hives. It can be used for store extensions and body sections used in the warm season. From it are collected cores, swarm traps, portable boxes in which you can temporarily contain layering, swarm bees.

Fiberboard, like plywood, does not tolerate high humidity. Can be used for interior walls and store extensions. Making bee hives entirely of fiberboard is impractical. The material is considered unreliable in service if applied to the outer walls.

Styrofoam (PPS) – modern material, actively popularized for use in apiaries. Beehives from it are very warm. Bee colonies winter well, gain strength faster in spring. These characteristics have been positively noted by foreign manufacturers. For example, the famous Finnish bee box models are made of PPP.

The disadvantages of PPP include low weight and fragility. Light houses can be knocked over by strong winds. They are defenseless against attack by rodents and birds.

It is convenient to work with teaching staff in a home workshop. You can read about it here:

Production of beehives from expanded polystyrene plates

Important point: Ventilation must be given maximum attention! If you overlook this, the nests will suffer from mold. And the concentration of water vapor greatly weakens the immunity of bees.

Styrofoam – one of the cheapest materials. Refers to polymers, like PPS. It has a low density – fragile and lightweight. Hence all the disadvantages – instability in strong winds, poor resistance to pests, intolerance to direct sunlight (it is destroyed faster).

Hives from it can be made as an alternative to more expensive houses made of expanded polystyrene (PPS) or polyurethane foam (PPU). But in practice, the operation has shown the fragility of the material.

It is advisable to use foam as insulation. Experienced beekeepers place a piece of styrofoam in the roof cover or use it to close the ventilation mesh on the bottom.

You can also make a beehive with your own hands made of polyurethane foam (PPU)that does not attract rodents. Like any polyurethane foam, it is resistant to dampness, decay, and retains heat well. The main disadvantage is that moisture quickly accumulates in the closed space of the dwelling. Therefore, good ventilation here is a prerequisite for keeping healthy bee colonies.

Types of bee houses

Bee houses differ in design, which depends entirely on the type, size and use of the hive.

A hive is selected taking into account the climatic characteristics of a particular area, the goals of the beekeeper – stationary maintenance or migration, bee breeds, and the strength of honey collection. All these points are well known to beekeepers who have been fishing for decades. Consultation with them is the key to success for beginners.

Hives are the basic equipment for any beekeeping industry. It is impossible to make a mistake in their choice, since changing the type of bee houses is an expensive and time-consuming undertaking.

Most popular models

Manufacturers who produce standard models of various hive systems divide them:

- on single-hull (meaning Dadans with extensions);

- for double-hull (two nest sections plus extensions);

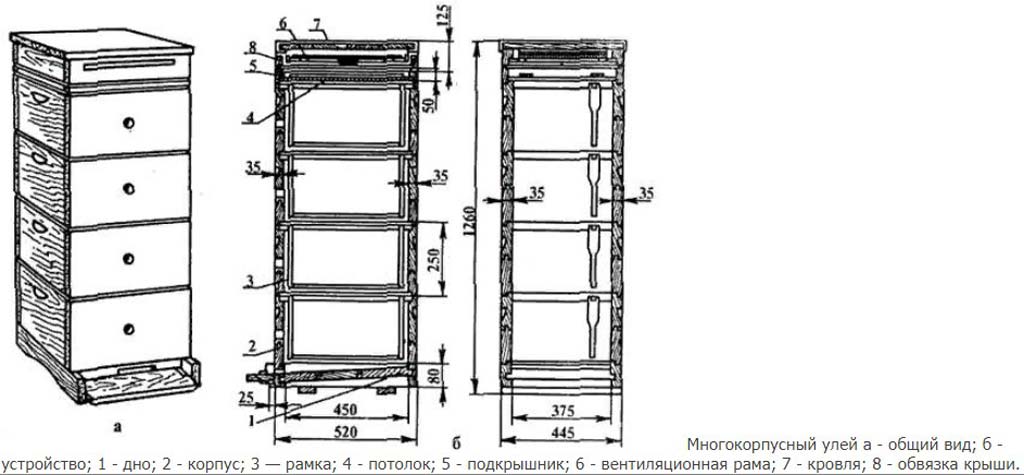

- for multi-hulls (several hulls or 3-4 hulls plus extensions);

- and on sun loungers (with or without extensions).

Hives, in which the development of bee colonies takes place in a horizontal plane, are suitable for stationary apiaries. They are convenient for novice beekeepers – when examining the nests, they are completely visible.

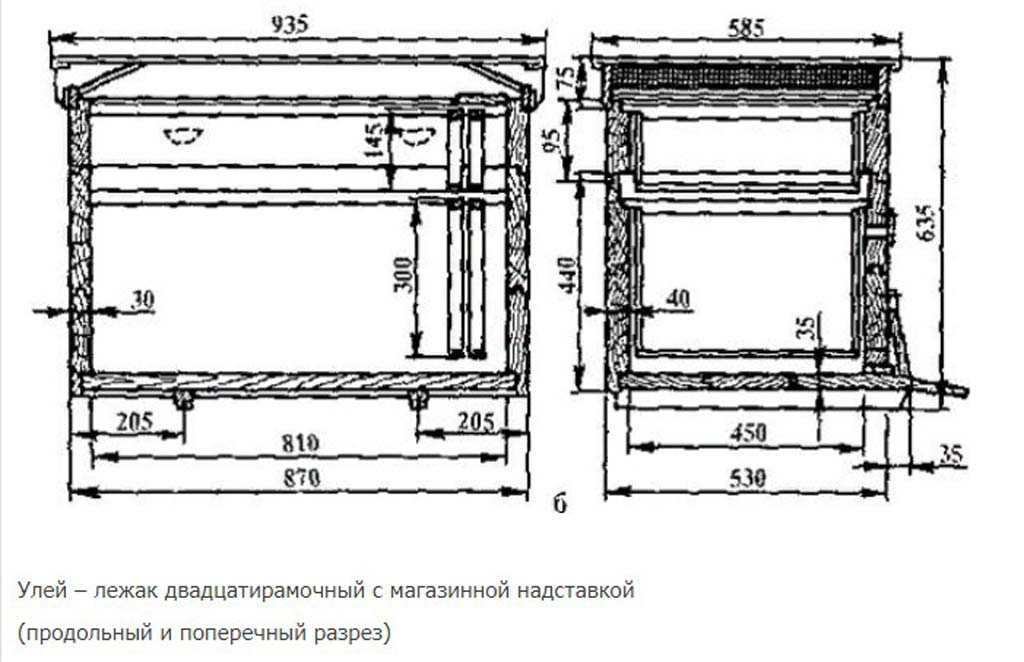

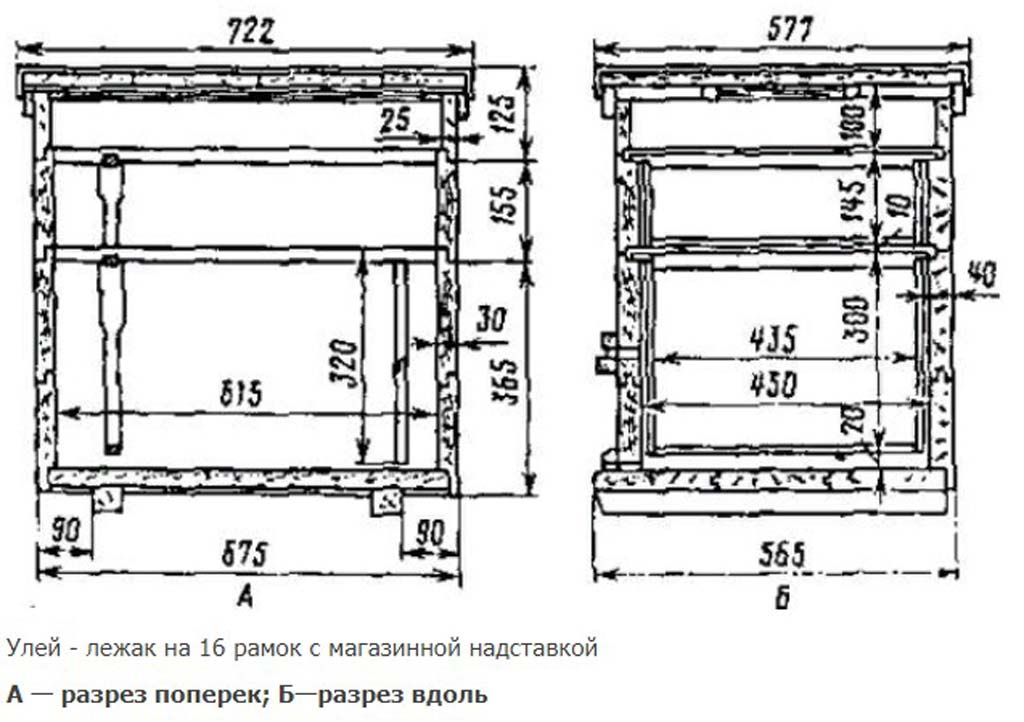

There are several types of sun loungers. A time-tested classic – a house for 20 or 24 frames. Another option is Ukrainian sun loungers designed for narrow frames (inverted by 90 degrees).

Making a beehive with your own hands can be done using the drawings and recommendations in the following articles:

How to assemble a beehive lounger with your own hands

Ukrainian beehive lounger

Plank bed from Fedor Lazutin

Vladimirsky lounger

Beehive 16 frames

The second popular variety is multi-body designs, in which the nests develop vertically. The riser models are also extremely varied.

The classic version is Langstroth-Root’s 10-frame multi-hive hive:

A hive from American beekeepers L.L. Langstroth and A.I. Ruta

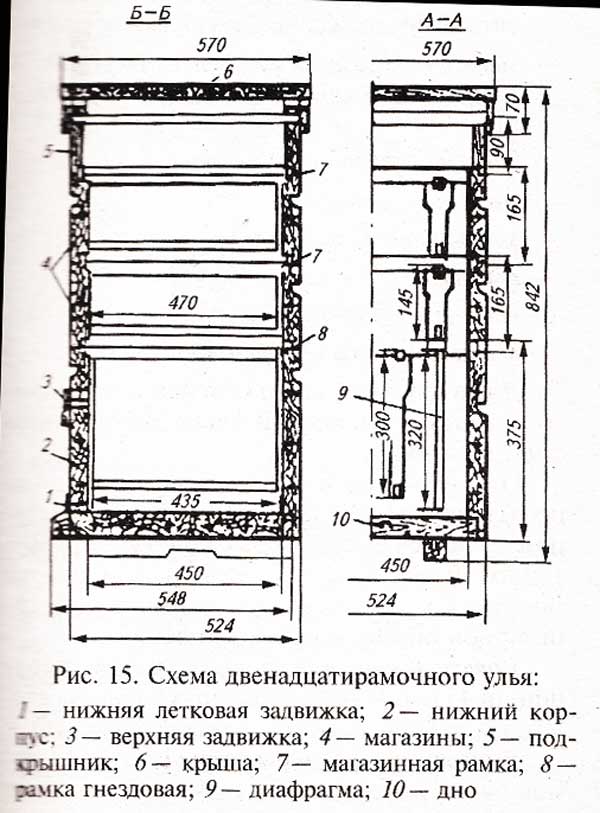

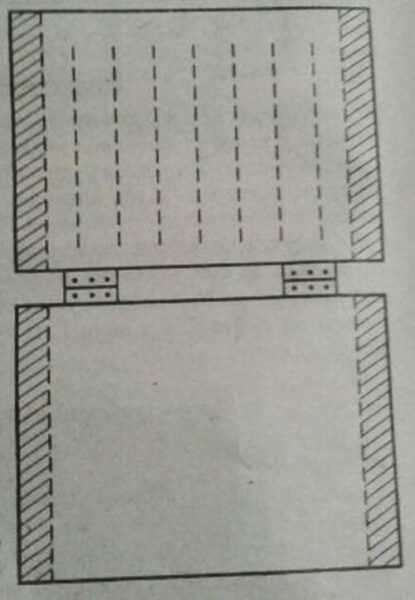

And the most popular risers (verticals) in Russia are Dadan-Blatt hives, assembled from one nest building and two store extensions. If the stores are replaced with a full-sized section, a two-part house is obtained.

You can read how to make a bee hive here:

Dadanovsky hive – features, advantages, manufacturing

12-frame Dadan

Dadant hives for 10 and 12 frames – which is better and why

We emphasize once again that the type of hives is selected based on the honey collection and climatic characteristics of a particular region. Beekeeping practice clearly shows that it is easier to operate with store extensions with half frames than full (nest) buildings.

The extensions are lighter in weight. And when pumping out honey, it is more convenient to free half-frames from bees, print and extract the final product from them. Such honeycomb frames are rejected less often, which allows creating a large stock of them. As a result, pumping can be carried out upon completion of the main flow without worrying about the lack of land.

Drawings of other multihull designs can be found here:

Beehive designed by Mikhail Palivoda (horned)

Beehive designed by Vladimir Petrovich Tsebro

Beehive Boa by Vladimir Davydov

The boa constrictor, in particular, belongs to small-format hives. The size of the honeycomb frame is 280 in width and 110 in height. The body section can be lifted and moved without removing the honeycomb.

Stands (verticals) are actively used in nomadic beekeeping. They take up little space on a platform or trailer. If necessary, the houses can be installed on two or three floors, since the bee colonies that have not yet gained maximum strength are sent to the blooming massifs.

Another interesting solution for wandering is cassette hives, which are similar in design to drawers.… They do not need to be unloaded. Service is performed directly on the platform. Moving along the aisle, the beekeeper puts out the cassettes and examines the bee colonies.

Each nest is fenced from the main space with horizontal plywood partitions. And the cassettes themselves are installed on guide bars mounted on the side walls.

In essence, this is a double-walled structure. The overall outer casing is assembled from 35 mm thick boards. Inside it, cassettes with bee colonies are inserted on the guide bars.

Structural features

It is impossible to make a hive for bees with your own hands without exact observance of the distance between honeycomb frames.

It is recommended to leave a gap:

- 37-38 mm between honeycomb frames (this is the distance from the center of the upper bar to the middle of the frame next to it);

- 7,5-8 mm between the walls and sides of the frames.

Moreover, the thickness of each honeycomb frame is 2,5 cm or 25 mm. The recommendations are correct for any design!

The body sections of most models are assembled by the panel method – the boards are connected into a tongue and groove. The joints are glued with waterproof glue. Usually, two to three boards go to the shield, depending on their width.

Cap may be:

- flat;

- lean-to with a slope back;

- gable with a crest in the middle line.

The backward slope is ensured by strapping – the front part is made higher than the rear one, the sidewalls are cut out accordingly.

Roofing material is used as roofing material (the cheapest and unreliable option), tin or galvanized iron. In the most modern models, protection from precipitation is performed using liquid glass. This coating absorbs noise and will last for many years.

Can be installed under the cover roof liner – warming mattresses are placed here, drinkers, feeders with sugar syrup are installed. During the transportation of bee colonies, a frame is placed here, tightened with a metal mesh, which prevents steaming and death of insects.

Потолок assembled from several separate boards. Sometimes they are knocked down for convenience with special stripes from the slats. In this case, the ceilings are easier to remove and reinstall. The ceiling is installed over the top bars of the honeycomb frames, resting on the seam of the walls.

Bottom assembled from a shield and strapping. Depending on the design, it can be:

- solid – nailed to the walls of the case;

- detachable – freely retractable and replaceable if necessary.

The kit may include two bottoms at once. The deaf is installed for the winter to save heat, and the net is used in the warm season (for example, this is done in horned hives) to enhance ventilation.

Body sections are boxes knocked down from four boards. Folds are selected along the front and rear walls inside them – protrusions are made for hanging honeycomb frames. On the front wall, tap holes are drilled for the free movement of bees.

The body of the lounger is completed with a non-removable bottom, has two admission slots – at the bottom and in the center of the front plane. Can be divided with blind partitions into separate sections for the simultaneous maintenance of two or more bee colonies under one roof. In this case, there will be more entrances.

Must be attached to the body arrival board – bees loaded with nectar and pollen arrive here. This makeshift “runway” is a must for any bee house. It can be solid with a bottom or folding – suspended on hinges along the front wall of the hive. The folding version is more convenient, since the board can be removed for the winter to protect it from mice or during transportation.

An example of mounting a body section is shown in the training video below:

Stores or add-ons by design, they resemble hulls with the only difference that their height will be less. Half-frames are installed here.

For ease of assembly and stability, all elements of the houses have grooves along the outer and inner plane of the walls. In some models, additional mounts are provided – for example, there are “horns” made of bars in Palivoda’s hives.

The package also necessarily includes:

- Diaphragms (plug-in boards)assembled from strips 14 mm thick. They are hung on the folds like ordinary honeycomb frames. Some beekeepers use rubber strips around the perimeter of the insert boards for a tighter fit.

- Dividing grids – used in vertical structures to restrict the movement of queens in the nest.

- Nest honeycomb frames… In individual designs, they are no different from other frames. For example, in Boa constrictors, horned hives, 10-frame multi-hull models (if no extensions are installed!).

- Half-framesused in store extensions. There are types of hives built exclusively on store frames – for example, the Horned and the Boa constrictor.

You can read about assembling frames with your own hands here:

How to make hive frames

Tools and equipment

It is impossible to make a hive of any design without special tools. Having a quality woodworking machine in your home workshop is crucial.

About which model of this equipment you can give preference, read here:

Which machine to choose for making beehives

And this article discusses interesting options for homemade units for working with wood:

Homemade woodworking frame machine

The minimum set of tools that a master needs to have is:

- hammers;

- chisels;

- drill with a set of drills;

- squares, ruler, tape measure for parts measurement;

- screwdriver or screwdrivers for working with self-tapping screws.

In conclusion, I would like to note that homemade hives can be with original dimensions and structural modifications. This is the main advantage of home build. It is no less profitable to manufacture strictly according to the drawings – as a result, you will get a high-quality house that has passed all the necessary tests in practice, but is 4-5 times cheaper than the factory model.