On large apiaries and on farms with multi-hull bee houses, a trolley for transporting beehives is indispensable. This is a must-have device that significantly facilitates the care of the apiary.

Often, the cart is assembled from scrap materials, because the main thing here is not beauty, but functionality and affordability. A self-made device is capable of performing all the functions inherent in an expensive factory-made apilift.

The content of the article

- 1 Trolley with lifting blocks

- 1.1 Installation procedure

- 2 Trolley with threaded lift

- 2.1 Installation procedure

- 3 General purpose trolley

- 3.1 Installation procedure

- 3.2 important points

- 4 In conclusion

Trolley with lifting blocks

We have already touched upon the mechanization of work in an apiary – we examined a homemade apilift and several models of carts developed by folk craftsmen.

This article can be found here: Trolley and scales – important homemade beekeeping products

Today we will continue the topic and consider other do-it-yourself carts for transporting beehives.

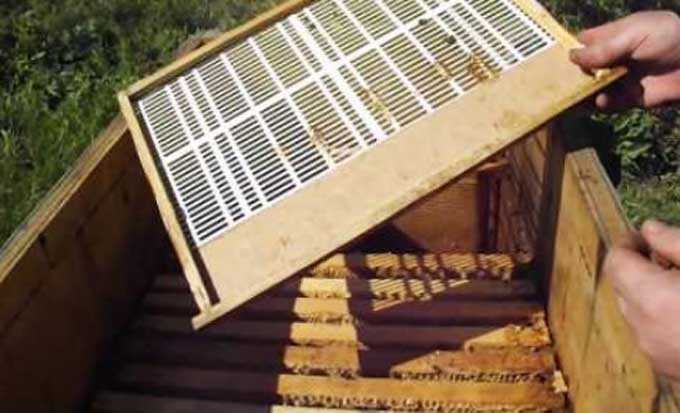

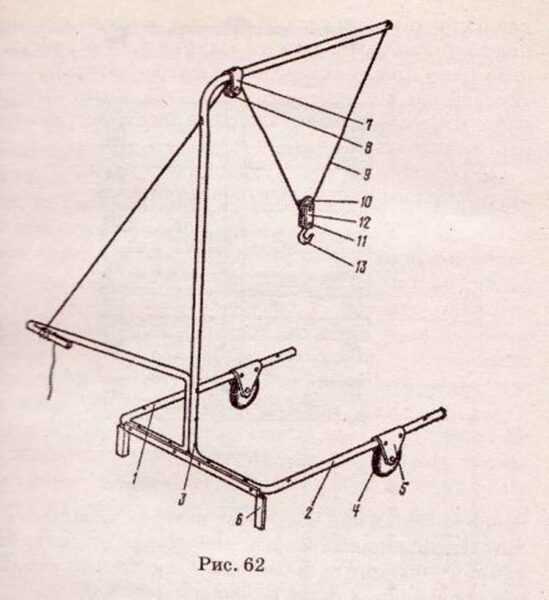

The trolley, equipped with lifting blocks, is mainly designed to move a set of frames… But we put it in the first place here, as a convenient means of mechanization for working with multi-body structures.

This device does not move the whole hives, but it makes maintenance of the hives much easier. The time for replanting nests is reduced, since wedge-shaped bars can be abandoned. A set of honeycomb frames can be easily transferred from one body section to another.

To do this, the cart is brought closer to the bee hive in such a way that its hook is strictly in the center of the roof, and the wheels go in on both sides of the house. After that, the taphole insert is removed, and the device is installed through the taphole slot on the bottom of the house. The cover is removed and the frames are raised by rotating the handle. Then the gripper installed on the weight hook is gently inserted under the shoulder tabs.

Honeycomb frames are suspended when changing bodies. They are lowered at the same time by removing the gripper rods. The handle of the mechanism is transferred to a horizontal plane – the pushers release the honeycomb, and they, under the weight of their weight, sit tightly on the folds. The freed body section is taken away on the same trolley.

Installation procedure

At its core, the mechanism is the simplest lifting device assembled from ropes and blocks. To lift something will require a force that is half the force of gravity of this load. The employee, losing in distance, wins in strength as a result.

Trolley with threaded lift

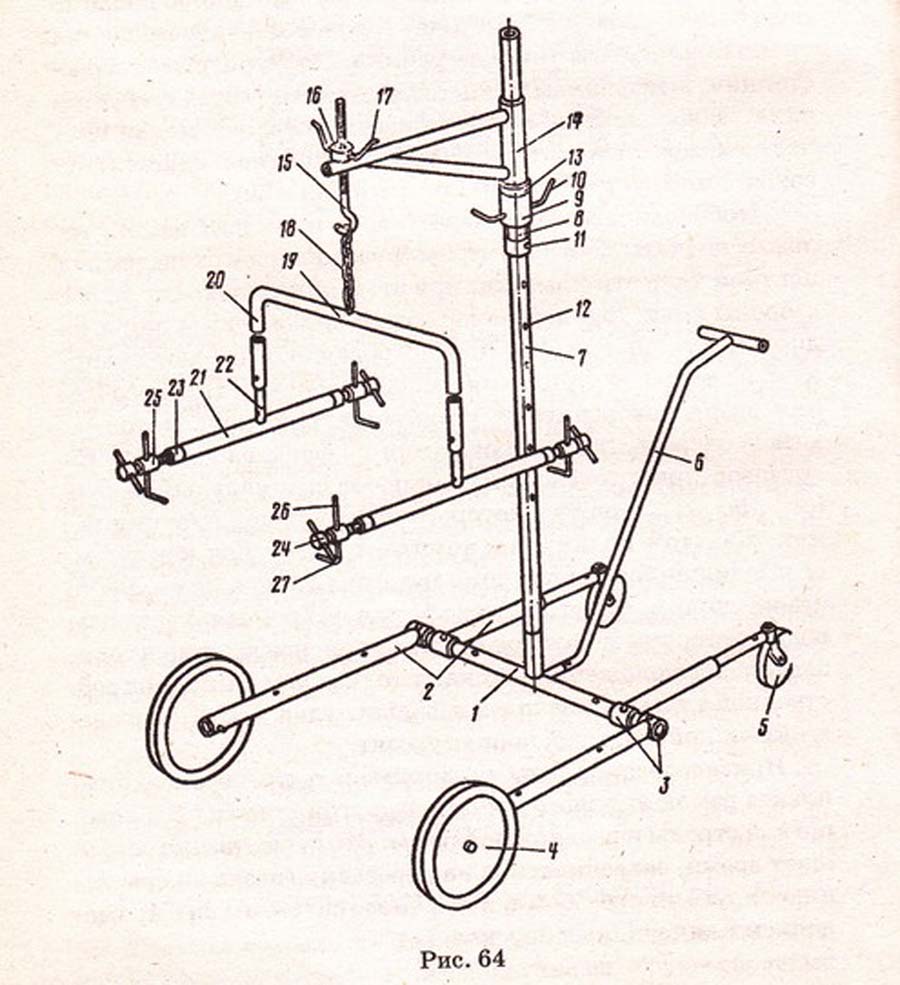

And this hive cart is closer in functionality to the classic apilift. It is adapted for convenient transportation of bee houses.

For transportation, the device is brought closer to the bee house, making sure that the wheels are on its sides, and the grip is above the roof.

Then the gripper bracket is lowered to the plane of the cover due to the rotation of the lifting rack coupling nut. In this case, the hook is at the top in the extreme position. After that, the horizontal rods are brought in, making sure that the clamps are below the plane of the bottom of the bee house. Through the holes, the clamps are additionally fixed with cotter pins.

Further, the clamping elements are wound under the bottom and clamped with wrenches. The swivel boom is lifted with the help of the coupling nut – the house is carefully removed from the detachable bottom, transported to a new place, and lowered onto a support prepared in advance. Then the clamps are released, and the transport mechanism is disconnected from the house.

Installation procedure

The mechanism is assembled according to the drawing as follows:

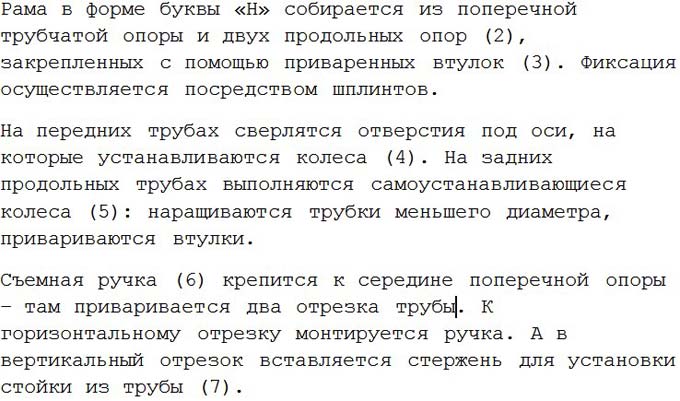

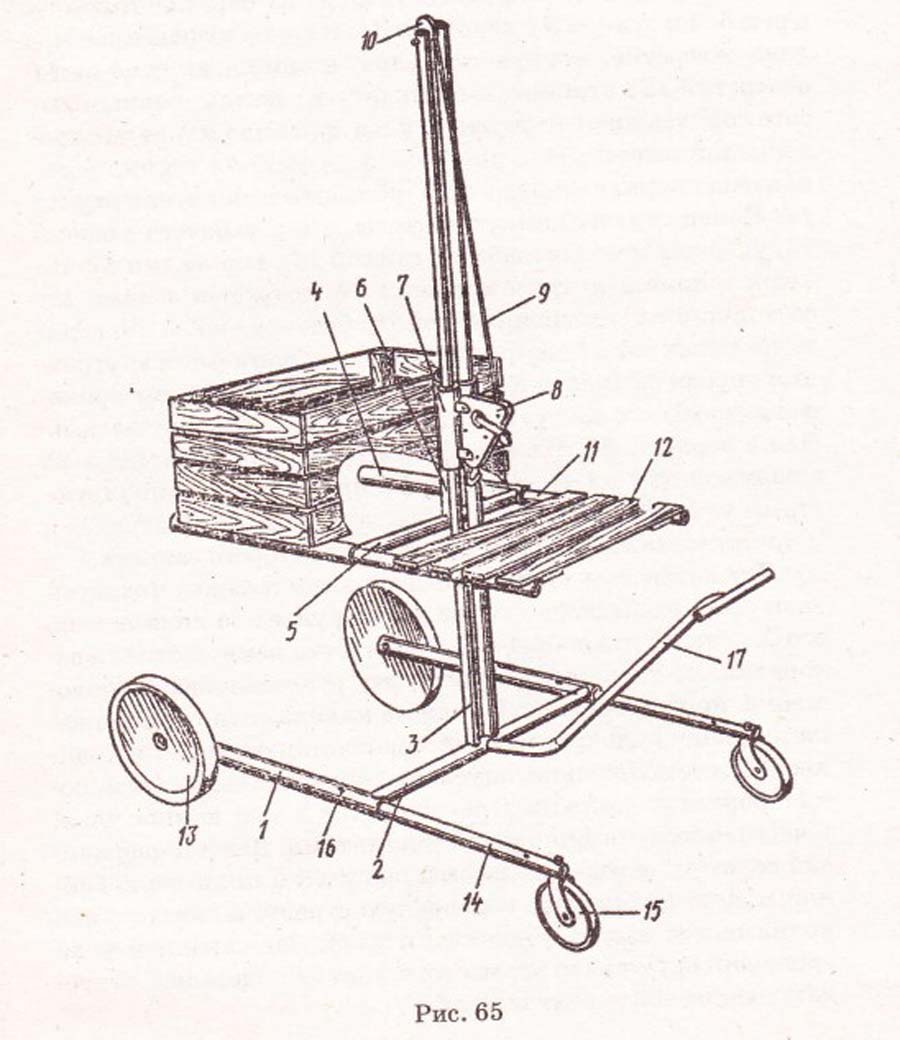

General purpose trolley

A homemade hive cart of this type can be used to lower bee houses or other cargo into a basement with steps..

To do this, lay 2 wide boards on the steps, equipped with guides made of bars (selected depending on the track – the width of the assembled transport mechanism). And a ladder is placed on the frame of a homemade hive cart, onto which a lifting fork with a load is lowered. The winch is removed from the mountings, the end of the cable is tied on the frame cross member close to the anchor point of the rack.

Then the winch is fixed with a strong stop (for example, a metal peg, a large tree, etc.). And then, by rotating the handle, the loaded cart along with the hives is lowered into the basement. After unloading, the device is pulled upward by a winch.

In a similar way, bee houses are moved to attics. The rope is thrown over the block, suspended at a point suitable in height for lifting loads. Then the second hook is attached to the cable. The lifting fork must be at such a level relative to the plane of the frame that, having rolled the cart to the lifting point, it can be easily pulled upwards together with the hive.

As a hanging block, resourceful owners use a roller from the rack of a home-made mechanism!

Installation procedure

A do-it-yourself hive cart is assembled using the following drawing:

important points

The dimensions of all parts of a homemade trolley with a lift are selected based on the dimensions and model (variety) of the hives available on the farm!

The weight of the beekeeper is also taken into account, which will be lifted on the ladder (12) installed on the inner telescopic pipes (11) – this is a kind of working platform.

It is important to take into account the maximum lifting height and dimensions of doorways in all buildings where the hives will be transported.

In order for the load fork to drop to the floor, its vertical stand is made slightly longer than the coupling tubes – it is extended by the radius of large wheels.

The fixture uses a single drum hand winch. It is attached to four brackets, which are fixed to the coupling with a weld. In this case, the bolts pass through the holes for fastening the cover.

You can adjust the tubes prepared for the coupling by cutting them along. If the tube does not fit, it is squeezed. And with an excessive gap, on the contrary, they distribute a little. Then, in the places of cuts, the tubes are tightly applied to each other and welded.

It is advisable to make the stand detachable. For this, the pipes are cut 15 centimeters above the frame level. Places of cuts are pressed in with metal rods. Then pipes of any suitable length can be put on them.

In conclusion

The costs of materials and all components for making the cart will be minimal, which makes this type of homemade products extremely attractive for beekeepers.

The owners get a convenient mechanism for transporting bee houses. And in the case of a trolley equipped with a lift, there is also a multifunctional platform for renovating buildings, spraying the garden, shaping tree crowns in spring, and other home gardening.