Feeders for rabbits are an integral part of creating favorable and comfortable conditions for domestic rearing and keeping animals. Equipped with properly made feeders, cages help simplify care.

- Varieties of homemade feeders

- Requirements and materials for self-made feeders

- Step instructions

- Cup constructions

- Hopper constructions

- Feeding troughs of the groove

- Feeding troughs on the advice of practitioners

- Instructions from Maslyakova

- Instructions from Zolotukhin

On large furry specialized equipment is installed on the farms, but if it is a home farm, you can significantly save If you know how to make a rabbit feeder with your own hands.

for rabbits

Varieties of home-made feeders

Do-it-yourself feeders can significantly save time while ensuring proper nutrition of animals, create the necessary sanitary and hygienic conditions in the cages, and also reduce feed costs.

The average domestic hare approaches the feeders 30 times daily.

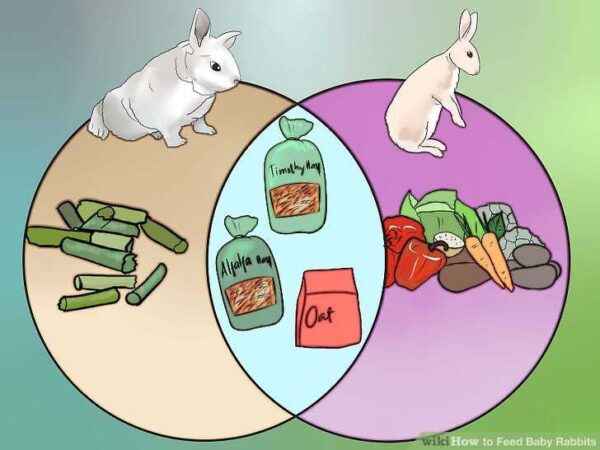

The ready-made manual and self-made automated feeders intended for feeding eared pets are divided into several main types:

- You can take a regular bowl as a bowl for rabbit food . This cellular inventory looks quite aesthetically pleasing, only it is not practical. Rabbits often overturn them with the available feeds, because they either remain hungry or require replenishing them again and again, spending more feed than usual.

- Mushroom-shaped feeders are used for grass and hay. Reviews of rabbit farmers speak about their practicality, they are the most convenient types of equipment, but you often have to monitor such devices and replenish them in a timely manner.

- Groove structures serve as containers for concentrated feed and root crops. Among the advantages of their farmers indicate the ease of access of animals to feed, and with a large accumulation of rabbits.

- Tin bunker feeders are more suitable for bulk mixtures and granular feed. Such feeders prevent animals from scattering feed and trampling them with their paws. The bunker feeders for rabbits (banks) are replenished once every few days, depending on the size, therefore they are suitable for those rabbit breeders who are not ready to devote a lot of time to feeding animals.

- Cup metal, clay and concrete feed devices are suitable for bulk or granular mixtures and can also be used in the form of drinkers. It is these types of equipment made of tin that are most often used on large farms.

It is important to remember that feeders and automatic drinking bowls for rabbits should be convenient for animals and most importantly as safe as possible. For example, a rabbit feeder is galvanized or made of tin and does not oxidize and the water in it remains clean for a long time.

If the farmer plans to breed fluffies with a constant increase in livestock, it is best if the rabbit cages and feeders are made large initially . In large cages for the convenience of the eared, you can install drinkers and feeders from the bottle. The installation scheme of such equipment is as simple as possible: drinkers from a bottle are suspended on one side of the cage. To strengthen such products, you can use metal hooks or fishing line. If fishing line is used, some hay can be placed as a sealant.

Requirements and materials for self-made feeders

When making a decision to make a feeder for rabbits themselves, it is necessary to take into account that the future design should:

- be roomy to avoid frequent replenishment of its feed,

- can be easily installed during operation and removed from the cage during cleaning,

- be safe when using animals, without sharp corners and protrusions that rabbits might get hurt,

- be accessible to animals and provide her order when they use feed,

- to prevent rabbits from getting their body parts, for example, paws,

- to mount out of direct sunlight.

A custom made rabbit feeder can be of different types of material. Suitable for this:

- thin tin and metal profiles,

- galvanized iron,

- wood, including plywood, bars and plank,

- plastic or plexiglass, including household items, for example, a plastic bottle and cups,

- slate.

Among the auxiliary materials that you need for the manufacture of do-it-yourself feeders for rabbits, wire, glass and rods, which are designed for sheathing the installation sites of feeders. As tools, prepare scissors for cutting metal, a drill with drills, pliers, a hammer with nails, a ruler with a pencil.

Step-by-Step Instructions

The technology of each type of rabbit feeders is similar to each other and does not cause difficulties in the implementation by hand.

Cup constructions

Decorative cup feeders do not require much effort, because all that is needed in this case is containers with smooth edges. In order to prevent rabbits from overturning these containers together with the feed, all that needs to be done with such a feeder is to properly fix it on the cage. To do this, feed cups are caked with wire for the holes made in the edges, either for the protruding parts, or for the bottom. In addition, they can act as a drinking bowl. Among the disadvantages of cup feeders is the inconvenience of cleaning when fastened to a cage. If you install bowls and cups in a recess (pit), they will eventually be filled with garbage.

Hopper constructions

For the independent manufacture of different types of hopper feeders for rabbits, wooden ones are required sheets that are subsequently upholstered in tin.Instructions for the manufacture of hopper devices for feeding include:

- measurements on sheets of iron and plywood in accordance with the dimensions according to the drawing,

- cutting according to the marked contours of parts, which include bottom, two side walls, front and back of the structure and the bearing crossbar,

- bending manually cut parts along the lines marked in accordance with the drawing,

- fastening tin sheets to plywood,

- collection of all parts into a single bunker structure.

A simplified version of the manufacture of a bunker feeder for I rabbits can be seen in the photo and video:

- on the basis of the paper layout is made according to the size of the drawing cutting of components from galvanized sheet with a thickness of 0.4-0.7 centimeters,

- cut the parts are bent, holes for fastenings are drilled into them,

- the components are assembled into a single structure and fastened with rivets.

As an original idea, some farmers propose building a bunker structure for feeding rabbits and rabbits from an ordinary plastic sewer pipe or canister.

Groove feeders

Groove rabbit feeders are designed for cereals, root crops and hay, they are made of either wood or metal. The standard sizes of such automatic devices are 50 centimeters one meter.Do-it-yourself mounting technology of a wooden structure involves:

- 6 boards for the longitudinal (two) and end (four) walls,

- connection at an angle of two identical parts for the end faces until equilateral a rectangle, as shown in the photo,

- fastening the long sides at an angle.

You can make the groove feeder yourself either from tin or galvanized.

Practical feeders

In the design of the animal feed, some rabbit breeders can use the advice on how to make the rabbit feeder itself.

Instructions from Maslyakov

Farmer E. Maslyakov has his own drawing of a bunker feeder for rabbits, which is based on a sheet of galvanized iron.According to its technology:

- according to the drawing dimensions on galvanized sheet or tin, the outline of two side walls, a lintel, an internal wall and a carrier for support by rabbits are made,

- accessories are cut and bent, as shown in the photo,

- holes are drilled at the joints of the structural parts, a number of holes are made in the bottom so that small debris falls out of the feeder,

- the components are joined together with rivets.

Many users have noted the convenience of such a makeshift design: bu Maslyakova nkra feeding trough for rabbits provides the opportunity to fill different feeds at the same time. two wooden sides. For them:

- the sides are cut out of wood according to the scheme, as shown in the photo by Zolotukhin,

- on a galvanized metal sheet or sheet metal, bastings are made and it bends according to them in accordance with with a drawing,

- with the help of screws and nails at the feeder, wooden sides with metal billets are assembled with wooden blanks, as shown in the photo by Zolotukhin,

- the device is mounted in the door, a grid is inserted into its frame, as shown in the video by Zolotukhin.

Among the advantages of using a feeder according to the Zolotukhin method – l Learning to save cell space.