Bees provide not only honey, but also other healthy foods. One of them – wax containing more than 300 valuable active ingredients – is now in demand in the home, medical and cosmetic industries. For beekeepers – owners of their own apiary – it is important to receive this product with minimal financial and time costs. This can be done using special equipment.

Of the several types of devices, one of the most successful options is the steam wax melter. A beekeeper can buy it ready-made or make it with his own hands from household appliances that have served their life.

What is the device

For a small apiary, an elementary home-made device is suitable. The device is designed to obtain wax from honeycombs by melting them under the influence of high temperature. The quality of the extracted material depends on the heating method. The wax begins to melt at 65-68 degrees, and the boiling point of water is 100 degrees. The raw material is heated with steam, which is generated in an autoclave built into the device or located nearby.

There are 2 types of steam wax pans:

- consisting of 2 vessels, the smaller one with the raw material is placed inside the larger one, in which the poured water is heated to the state of steam entering through the holes into the container with the raw material;

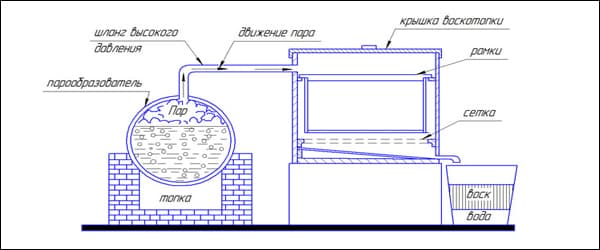

- 2 separately located tanks, in this case steam is supplied through a pipe that can withstand high-temperature conditions.

The melted pure wax flows into a special tray for collecting the finished product. The result is a clean product due to the fact that the honeycomb does not directly contact with water.

Helpful information!

Stainless steel fixtures last longer but are more expensive than aluminum fixtures. When working with them, the risk of getting burned is minimal.

How a steam wax melter works

The simplest device is a metal case, on the bottom of which water is poured. A metal grid or mesh bags with ground raw materials are placed on top. The container is placed on a stove or other heat source, brought to a boil when the water begins to evaporate. The softened wax melted by hot steam passes through a filter that retains foreign impurities, flows into a special tray and is cooled there. The clean wax can then be easily removed from the device.

Advice!

After heat treatment, the discarded honeycomb usually contains pomace containing sufficiently pure wax. It can be removed using special presses.

An alternative design with an external heater, equipped with a pipe for supplying steam to the container with raw materials, placed on special holders. The melted wax enters the lower compartment of the vessel through the filter mesh along the inclined sheet, leaving foreign additives on it. The substance flows down with the water, they are separated due to the difference in density: the liquid remains at the bottom of the tank.

Important!

The tube for draining the resulting product is taken strong, capable of withstanding high temperatures and spacious enough in diameter so that you do not have to clean clogged passages too often.

Types of steam wax pans

Home-made equipment for the processing of crushed raw materials operates on the basis of the principle of a water bath, where there is absolutely no contact of raw materials with liquid. The result is environmentally friendly products, and with additional processing, the merv is completely dried up.

There are 2 categories of devices:

- A gravity device in which the frames are treated with hot steam at atmospheric pressure. At the same time, the water is heated in wood-burning stoves or on electric stoves.

- Pressure plant equipped with a mechanism for compressing the loaded raw materials. This creates a pressure above atmospheric. This effectively increases the yield of the finished wax without an additional press. In fact, the structure is already equipped with a press to reduce the size of the wax firing chamber. The temperature of the water increases due to the heat obtained by the combustion of solid fuel, gas. The use of electrical appliances is possible.

Hand-made production

Due to the high cost of the finished device, beekeepers usually make a steam wax melter with their own hands. Its manufacture from scrap materials, used household appliances is not difficult. Savvy beekeepers adapt metal containers of any volume to the base for melting wax:

- old barrel;

- large tank;

- a large saucepan;

- waste steel gas cylinder;

- case from an old washing machine or refrigerator.

The main condition is that the frame must withstand high temperatures.

Simplest design

An elementary steam structure, the manufacture of which is available even to a novice beekeeper, is a metal container in the shape of a cylinder, to the middle of which water is poured. A mesh container is placed on top of it, fastened with hooks to the edges of the tank. Raw materials to be processed are put there. The vessel is placed on a heat source, brought to a boil. Rising, the steam melts the wax, which flows down and, after cooling the water, solidifies on top of it, without mixing with it.

Frame steam wax melter

The unit of its own work consists of two metal containers that fit one into the other. Through holes are drilled in the lower part of the inner tank, frames made of wood with honeycombs are fixed on the upper edge with hooks. Under the bottom there is a drip tray for the melted wax. In an outer vessel with a lid that ensures a constant temperature, steam is generated and distributed by heating using an insulating material.

The advantage of a home-made steam frame wax melter is the possibility of processing the honeycomb without crushing and removing it from the frame.

Helpful information!

Heating wooden structures disinfects the surface and cleans it from dirt.

From the washing machine

Waste household appliances designed for washing linen are the perfect option for creating a homemade steam wax pot. The 40 liter stainless steel tank is the best kind of collection for raw materials.

Remove the bottom, replace it with a welded steel grate. An aluminum tray is installed in the upper part of the tank for collecting raw materials. Its edges are precisely aligned with the sides of the tank so that the vessel fits snugly on top of the device. Experienced craftsmen use a special support for this. For convenient access of steam to the raw material, small holes are drilled along the edges of the tray.

The finished 2 cm tank is immersed in a large pot filled with water and placed on the stove. Place dry in a tray and cover with a lid. In such a device, you can simultaneously process up to 25 frames. After the end of heating, high-quality melted wax is taken from the aluminum bowl.

External steam generator manufacturing

The hand-made installation of an external portable unit for generating steam is available to the novice beekeeper. It increases the capacity of the wax melter, needs minimal financial costs. The device is a metal container with an opening for filling water and a wide branch pipe for removing steam. The speed and productivity of steam generation is due to double heating (from the heat source and the pipe).

According to the instructions, the equipment is placed on a refractory support above the hearth or gas burner. After the water boils, the evaporated steam flows through the attached pipe into the working area of the wax melter, it condenses in the lower part of the tank. For the stove, they often take a used converted gas cylinder.

Important!

The beekeeper needs to control the water level in the tank.

Using a steam wax melter

In such a device, crushed honeycombs and frames are melted as a whole. For one load, you can get about 10 kg of pure wax from 5 kg of starting material. Having started the device, the beekeeper only needs to monitor the level of loading of the unit with raw materials and change trays for the flow of the resulting product. After cooling, the solidified substance is removed by hand.

Now they are trying to equip the heating boiler with a tubular electric heater, fixed at the bottom of the tank with a thread. Connecting to the network makes the task of the beekeeper easier, eliminates smoke and problems with the preparation of firewood, making fire.

Advice!

After melting, the remnants of the mortar can be melted again by turning it over several times, and at the same time another 25% of the wax can be obtained.

Advantages and disadvantages

The steam wax melter is one of the most important tools of the beekeeper. Melting wax with steam is now a fairly common way to obtain a valuable environmentally friendly product. The advantages of the device are:

- in the simplicity of manufacturing the unit and performing the melting process itself;

- in high efficiency of the output of the finished material;

- in a low content of water in the wax, which increases the quality of the product;

- in effective cleaning of raw materials from impurities and additives in the conversion process.

A significant disadvantage of the device is the serious consumption of electricity or the preparation of solid fuel to create the desired temperature regime. Homemade installations usually lack a thermostat, which often causes the wax to overheat and deteriorate.

A steam wax melter is a necessary tool for a beekeeper to obtain a valuable beekeeping product that brings additional income. It is easy to make it from scrap materials and used household appliances.