Beekeeping, regardless of its size, requires the repair of old or the production of new hives, frames, portable boxes, swarm traps. Someone chooses the path of permanent investment or reinvestment – investing in the purchase of the listed products. Others are creative – they make everything with their own hands, getting a lot of pleasure from carpentry work.

A homemade machine for making frames for beehives is just the type of equipment that every beekeeper should have on the farm. Of course, assembling such a homemade product is possible only with sufficient possession of the necessary skills.

The content of the article

- 1 Work specifics

- 2 Examples of homemade machines

- 2.1 1 Videos

- 2.2 2 Videos

- 2.3 3 Videos

- 2.4 4 Videos

- 3 In conclusion

Work specifics

Theoretically, you can cut out blanks for frames using a saw equipped with a fine-toothed blade. Some craftsmen use an electric jigsaw. With its help, individual parts are cut. But these are all half measures.

The woodworking machine significantly speeds up and simplifies the work. The frame is made in literally two or three well-adjusted movements.

Of course, the rotational speed of the saw blade of the machine requires special attention to safety from the home craftsman. It is necessary to concentrate completely on filigree work. Only in this case you can count on success in manufacturing and safety for your health.

You might be interested in:

How to make hive frames

The following points are worth paying special attention to:

- A homemade machine should be grounded in the same way as any high-quality factory model of this type.

- Its dimensions are selected depending on the needs of the owner. There are well-known cases when a bulky “grandfather’s machine from the village”, perfectly working on a stationary basis, cannot be transported to another apiary.

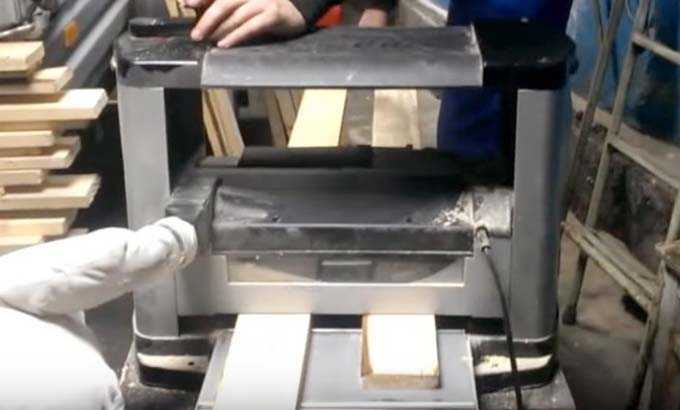

A good alternative in this case would be a small household machine, for example, such as in this photo:

Obviously, you will have to focus on the dimensions in the manufacture of homemade products, if we are talking about its free transportation or movement within the workshop.

Examples of homemade machines

The network contains many options for making a homemade machine designed for the production of beehive frames. Craftsmen willingly share their ideas in short videos, however, without providing detailed assembly instructions. Often the viewer has to rely on his own ingenuity and knowledge available in his luggage.

Team . made a small selection of such video reviews to inspire my readers and give them interesting creative ideas.

1 Videos

This woodworking machine uses a three-knife drum with a blade width of 250 mm. The feeding and receiving table are made of 8 mm thick sheet steel. A single-phase motor with a factory-assembled capacitor of 2,2 kW at 2 rpm (manufactured in Mogilev, Belarus) is used as a drive. It can be ordered from the online store.

The motor is mounted on an 8 mm sheet steel table. The drive is assembled from two pulleys – 80 and 110 mm, on which the belt of the KAMAZ generator is put on. The launch is carried out through a magnetic starter. The equipment is designed for the production of honeycomb frames and hives.

2 Videos

And in this version, the master made an additional table made of marine plywood, resistant to moisture and stress, which covers the jointer. You can buy plywood from boat repair companies.

There is an easy-to-use device for cutting strips, bars.

3 Videos

Below is a simple planer sawing machine, the bed of which is assembled from a 40 x 40 mm corner. To make it you need:

- 4 corners 450 mm long;

- 9 corners 550 mm long;

- 2 corners 270 mm long;

- hairpins M12;

- nuts;

- washers;

- a drum purchased at a flea market;

- knives purchased from a hardware store, 200 mm long;

- 2 strips for the electric motor;

- 2 planing tables 300 mm long and 220 mm wide;

- 1 sawing table 600 mm long and 220-230 mm wide.

Note: Tables can be not only iron, but also wooden, textolite.

For the assembly order, see the video suggested by the author:

Disadvantages of the design: the machine is not adjustable, and prolonged operation of the unit can lead to loosening of the bed nuts. Undoubted advantages: low cost and simplicity.

4 Videos

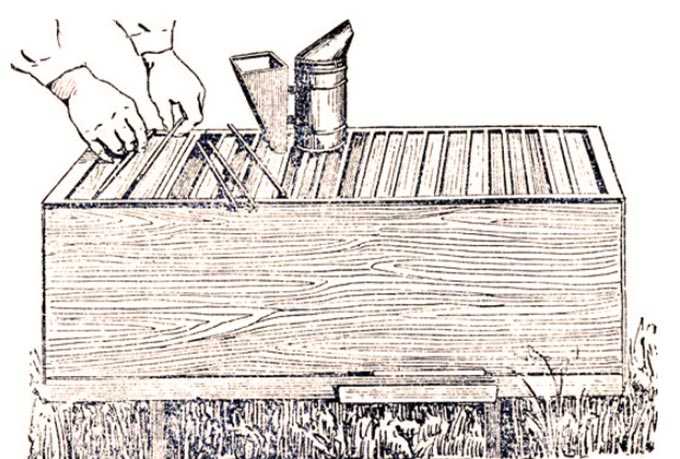

And this is a multifunctional and very compact machine, equipped with a planing table with a difference between the receiving and feeding sides of 6 mm. The length of the table is calculated in such a way that a third of the side bar can be freely measured along it during processing. Drilling holes for the wire is done using a special template.

In conclusion

These are interesting solutions offered by folk craftsmen for home-made machines designed for the manufacture of frames and beehives. What kind of creative idea to implement is entirely up to you.

Depending on the model, for the manufacture of individual parts of the machine, you will need milling, turning, and welding equipment. Or you will have to seek help from the appropriate specialists.

An alternative to homemade products is the Master-Universal 2500E from the Belmash company. It is a versatile woodworking machine that has the function of drilling, sawing, planing and milling with a finger or disc milling cutter. As a drive, an asynchronous electric motor with a capacity of 2,5 kilowatts is used, which can be easily connected to a household power supply. A work table is required to set up the machine.