Disputes about the size of the frame do not subside until now, because labor productivity and the profit of the apiary directly depend on them. They also affect the size of the bee housing and the choice of the type of hives.

The fateful congress of beekeepers in Russia adopted uniform standards in 1918, making small-format hives something forbidden and unpopular. Although such systems are successfully operated in other countries, small-format beekeeping is still viewed with great skepticism today. The general opinion is formed by the long-term practice of using the Dadan-Blatt and Langstroth-Root hives – the same “standard beekeeping systems” recommended at the beginning of the last century.

The content of the article

- 1 What is MFP

- 1.1 Problems of using MFP

- 1.2 Why Small Format Systems Are Good

- 2 Notable designs

- 2.1 Udav

- 2.2 Alpine

- 2.3 Krylatsky

- 2.4 “Amur”

- 2.5 “Force”

- 2.6 Henda

- 3 In conclusion

What is MFP

There are a lot of small-format bee dwellings. These are both well-known systems such as the alpine hive, and handicraft developments of domestic beekeepers. Which sometimes offer very original solutions, such as altering Dadanov or Rutov into 8-frame structures of a small-format type.

They are united by one common feature – the internal dimensions of the nest are approximately 1,5 times smaller than the standard one. The width of honeycomb frames ranges from 300 to 350 mm. In horizontal section, such a nest is close to the natural size of a bee club.

Problems of using MFP

It is extremely difficult for beekeepers “small-sized” to find the necessary information on the maintenance of bees – in our country there are no scientific works, reference books, practical developments in this area.

Lack of experience is a major problem with small format hive systems. Each of the enthusiastic beekeepers follows an experimental path, acting at their own peril and risk.

Why Small Format Systems Are Good

The MFP hive has a number of advantages, the most important of which is the ability to operate with entire cases. And the weight of the body sections will be really small. What makes such hives a good choice for beekeepers with disabilities – elderly people, women, adolescents.

Other positives are:

- More successful wintering due to the reduced height of the nest, which is important for the northern regions.

- Convenience when pumping out commercial honey. If you use standard frames, in conditions of weak flow, both honey and brood will be placed on them at the same time. Such a problem is not observed when reducing the size of the honeycomb – the bees have time to fill the entire frame with nectar.

Notable designs

Having separated into a separate branch, beekeepers “small-sized” began to develop different designs of hives. But here, too, it was not without controversy! The leaders were beekeepers, whose perseverance and skill testified in favor of the invented design. Lesser known design combinations are less widely used and have earned less popularity.

Udav

Boas are one of the most popular small-format solutions. They are multi-body systems assembled from 10-11 sections. The height of the hive during honey collection reaches 1,5 meters.

The yield of honey from one bee colony is 50-60 kilograms. The weight of a full-length frame is about 0,8 kg. Commercial honey can be sold as a honeycomb.

You can read more about the design here:

Beehive Boa by Vladimir Davydov

Its main advantages:

- light weight;

- ease of manufacture;

- ease of maintenance;

- the possibility of assembling lumber from waste – cuttings with a length of 30-40 and a width of 13-15 cm are used;

- minimum equipment – the system is assembled from the bodies, the lid, the combined bottom, the dividing grid and the lap (oilcloth on a fabric basis).

Alpine

This multi-body design was designed by Roger Delon. Internal dimensions 360 by 230 millimeters. Frames are assembled from one bar and wire. The length of the bars is 320 mm. The keeping of bees in such hives is practiced by the Russian beekeeper Khomich. Detailed drawings of the Alpines belong to his authorship.

Beekeeping in alpine hives is as close as possible to the natural needs of bees. Insects rebuild honeycombs themselves in the same way as in decks, Japanese hives, and Abbot Warre’s systems.

The adaptation of the bees to the new system is a major design problem. Insects learn to build combs without artificial foundation during one season – during this period the beekeeper accumulates their stock. From the second year, when ready-made combs are used for expansion, the hive will start to make a profit.

The selection of marketable honey is made when 5 hulls are filled with nectar. Bees hibernate in two body sections.

Krylatsky

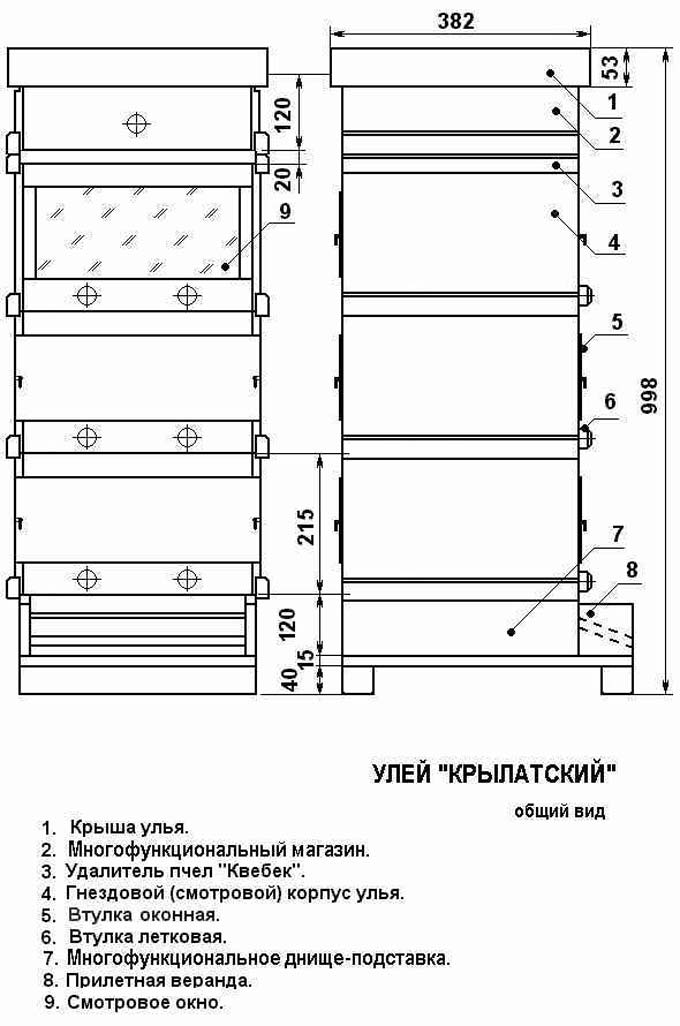

The idea for the construction of this multi-body, foldless hive belongs to V.P. Kuryshev. The main feature is the presence of viewing windows with bushings on the housings. Thanks to this, 40 hives in the apiary can be quickly examined in just 30-40 minutes.

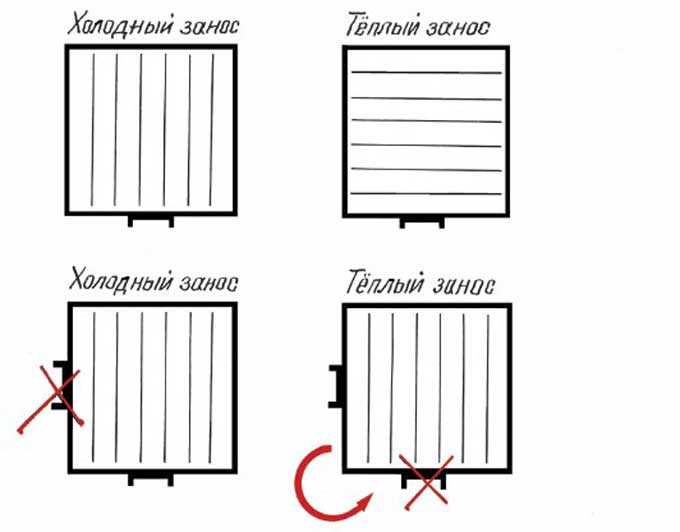

The height of each case is 215 mm. There are two tap holes for organizing a cold and warm drift (installation of honeycombs perpendicular or parallel to the tap hole). Two walls are made of glass or polycarbonate, which allows visual control of the nests without interfering with the life of the family.

Weight when fully loaded with honey is up to 20 kg. The empty case weighs 3 kg. The hive is completed with five body sections. Roger Delon honeycomb frames are used – with a wire perimeter.

You can additionally install one magazine, which is half the height. The store extension is used for obtaining sectional honey, placing a warming pillow or drinking bowl, withdrawing queens, drying frames after honey pumping.

Bottom with high subframe space and removable mesh tray. There is a tap hole of 300 x 7 mm. An electric heater can be installed instead of a pallet.

The cover is flat with a strapping of rails. It is pushed onto the upper body.

“Amur”

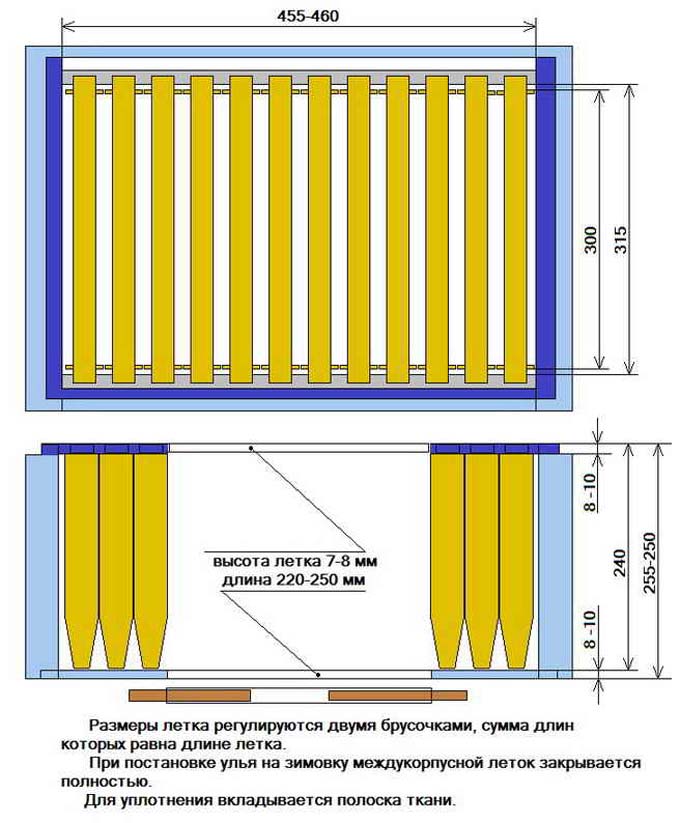

This experimental hive, similar in design to the Udav, was proposed by Yuri Priyma from the Amur Region. But the frames here are narrow, twice as high as the Udavov ones – 240 by 300 mm.

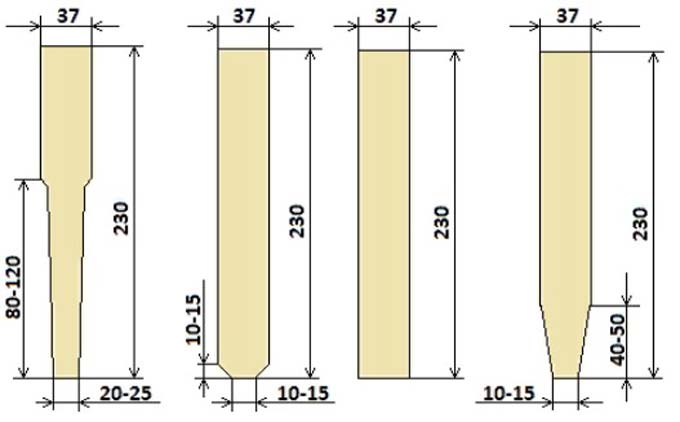

In this case, the honeycomb frame can have a different shape of the profile of the side bar.

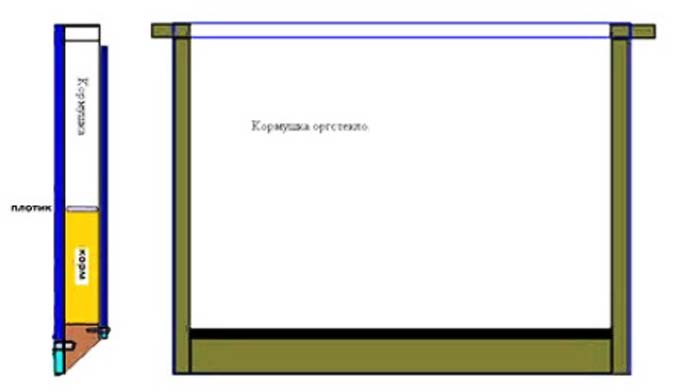

Feeders are mounted from bars 25 x 25 mm, 5 mm plastic or plexiglass. In terms of dimensions, they are equal to the Amur honeycomb frame. From the side of the honeycomb, one of the walls of the trough is made lower by 3-3,5 cm, which makes it easier for the bees to access. A “raft” made of a wooden plank floats inside.

Case dimensions: 245 in height, 315 in width. The length is selected depending on the number of used honeycomb frames plus 1 mm allowance for each frame. You can set an even number of honeycombs – from 8 to 14 pieces.

This hive is ideal for the Far Eastern bee population seeking to build combs between adjacent enclosures, connecting them together.

It is completed with 3-5 body sections, a liner, a cover, a bottom with an inclination, a dividing grid and a lap made of a polypropylene bag or cloth on an oilcloth basis. The connection of the bodies is folded.

It is made from sawn timber waste – scraps of bars and even dry firewood, according to the frame technology proposed by Lazutin. Foam is used as insulation. The thickness of the bars for the frame is 40 by 30 mm. Waterproof plywood is suitable for interior cladding.

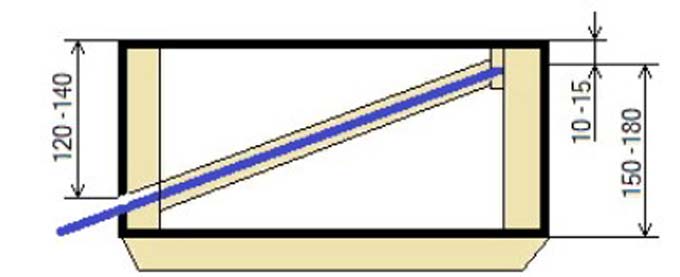

The underframe space has been increased to 12-14 cm. The floor is inclined, made of plastic cladding panel and installed on guide rails. It is easily cleared of dead wood without removing it from the hive.

The cover is made according to the classic scheme – a board made of boards, strapping.

“Force”

A hive of this design is suitable for the northern and central regions of Russia. One Sila hull can be used as a double core. For this, a diaphragm is installed in the middle, as well as a bottom with a partition and overhangs in opposite directions.

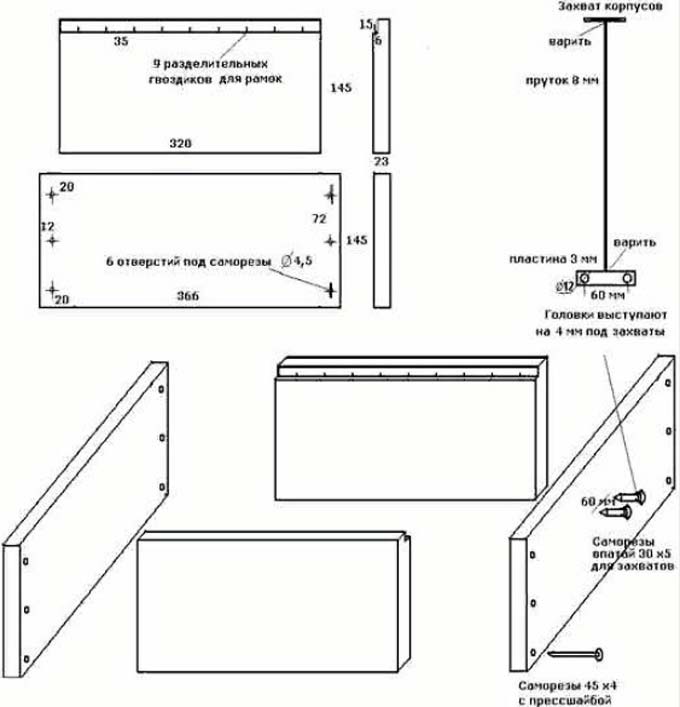

The body is assembled from 150 mm boards 25 mm thick. Internal dimensions 320 x 320 mm, height 145 mm. The side joints are fastened with self-tapping screws with press washers. A notch with a diameter of 13 mm is drilled on the front wall.

Folds measuring 15 by 6 mm are located on the end sides from the inside. The frames are set at a distance of 35 mm, which is 2 mm less than the standard. One body contains nine honeycomb frames.

Outside the side walls, two self-tapping screws are screwed in to install the grips (analogue of handles).

The cover is flat, made of plywood. The sub-roof is equal in size to the body. On the end walls it has four ventilation holes with a diameter of 25 mm, closed with a fine-mesh metal mesh.

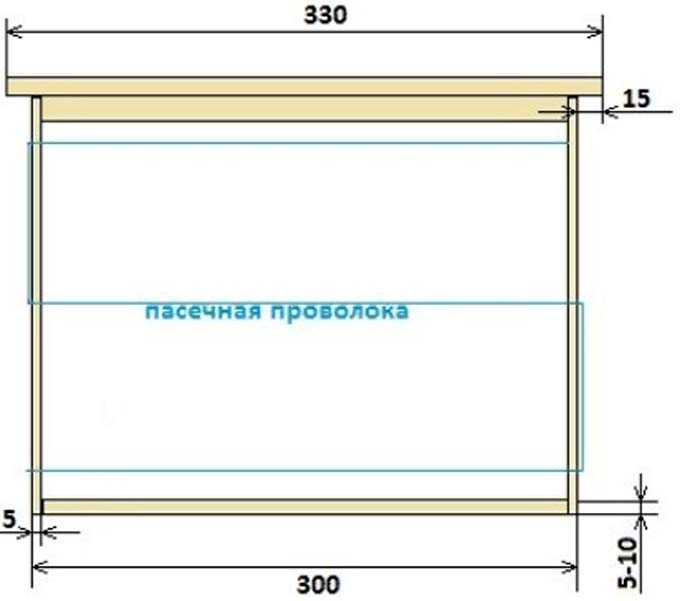

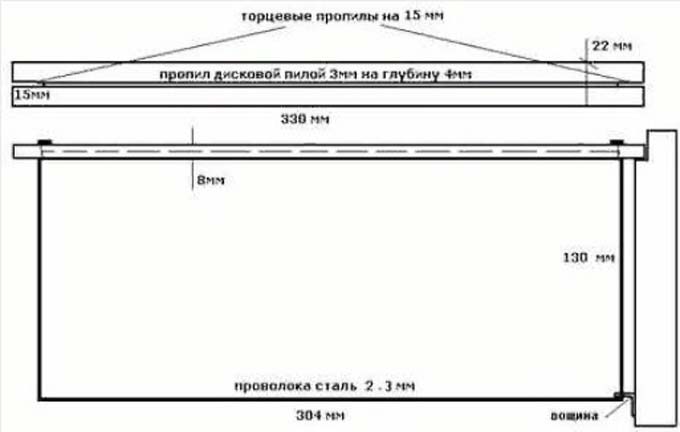

A honeycomb frame is an upper bar 330 mm long, 22 mm wide and 8 mm thick, complemented by a wire perimeter. The recommended wire thickness is 2-3 mm.

To fix the foundation in the bar, a longitudinal cut with a depth of 4 mm is performed. The wire is also installed using cuts – 15 mm grooves are made at the ends of the bar. To prevent the foundation from sagging when rebuilding the honeycomb, it is additionally reinforced on the bar with drops of wax.

During the adjustment, the bees attach the frames to the end walls of the hive. To remove the honeycomb, you must cut off the wax lintels with a sharp knife! Then, using a wire hook in the form of tongs, they are removed for pumping.

Henda

Hand’s multi-hive hive is designed for the production of sectional honey. The honeycomb frame used here is 450 mm wide and 125 mm high. Moreover, the upper and lower bars have a small width (21 and 12,5 mm), making it easier for the beekeeper to visually monitor the state of the frames.

Each body is equipped with 8 honeycomb frames closely adjacent to the hive walls – the space on the side of the honeycomb is completely blocked for the passage of bees.

To obtain sectional honey, I place four sections in each of the honeycomb frames, equipped with wooden gratings for uniform alignment of the honeycomb. For this reason, only six frames with installed sections are included in one body.

The honeycomb frames are removed through the hinged side wall, which opens at the top (the bottom remains stationary).

Up to six enclosures can be installed in total. Wintering takes place in two hull sections.

The bottom is mounted from a flap, on which strapping bars are stuffed from three sides. In this case, the entrance gap is obtained in front of the entire width of the hive. The arrival board is also located here.

The cover is flat, assembled using frame technology. Inside there is a straw mat insulation. The hive is protected from precipitation by white-painted sheet metal.

In conclusion

In the beekeeping industry, everything is interconnected! Choosing the “right hive” is only half the battle. Climatic and weather conditions, peculiarities of a particular area, cultivated bee breed, conditions of its keeping – all these are factors that are the key to success … which, unfortunately, no one can guarantee to a beginner.

It is not so important which hive system was chosen – small-format or standard. The main thing is the skills of the beekeeper. After all, any beekeeping technology is based solely on knowledge and experience. This means that it requires skill acquired over the years.