This design of bee houses is intended for areas with abundant honey collection. The multihull hive is shaped like a tree hollow – the natural home of wild honey bees.

The apiary, consisting of such houses, is quite consistent with the natural habitat. That has a positive effect on the profitability of the beekeeping industry.

The content of the article

- 1 How the hive works

- 2 Advantages and disadvantages

- 3 Dimensions and assembly features

- 3.1 Frame dimensions

- 3.2 Dimensions of the entrance

- 3.3 Bottom dimensions

- 3.4 Ceiling, liner, cover

- 3.5 Acceptable errors

- 4 Conclusion

How the hive works

The bee house is formed in two versions:

- from five to six full-fledged buildings;

- of three buildings and the same number of store extensions designed for storing honey.

Each of the enclosures accommodates ten frames of the standard size for the design – 435 x 230 mm (43,5 x 23 cm).

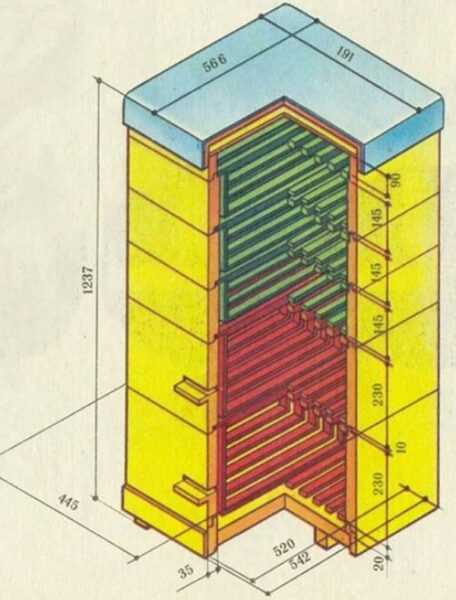

This is how the assembled structure looks like:

The main details here are:

- bottom;

- housing;

- the shops;

- ceiling;

- roof liner (used for insulation);

- cap.

During wandering and transportation, the system is fixed with special fasteners made of metal bands or locks that prevent accidental disconnection.

And the revolving detachable bottom allows you to change the subframe space (basement) depending on the season – in winter, the height is lower.

Advantages and disadvantages

In operation, the design is quite simple. It is easy to assemble and disassemble. All elements are interchangeable, that is, housings and magazines, if necessary, can be rearranged from one hive to another.

When transporting such narrow hives, more are placed in a row than houses of other designs. Inspection of frames is easier here – less free space is required. The magazine top is noticeably lighter than the 12-frame Dadant.

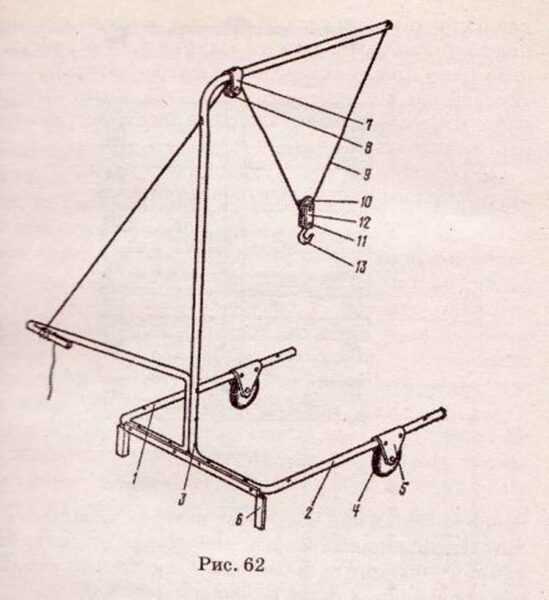

The disadvantages include the large weight of each individual case, fully loaded with frames. Beekeepers with such houses work in pairs or use lifts.

The multi-hull design is not suitable for beginners who are just mastering beekeeping and go out to inspect the apiary alone.

Dimensions and assembly features

Hive bodies are assembled from soft woods. The recommended building material thickness is 3,5 cm (35 mm). Details are connected in a quarter.

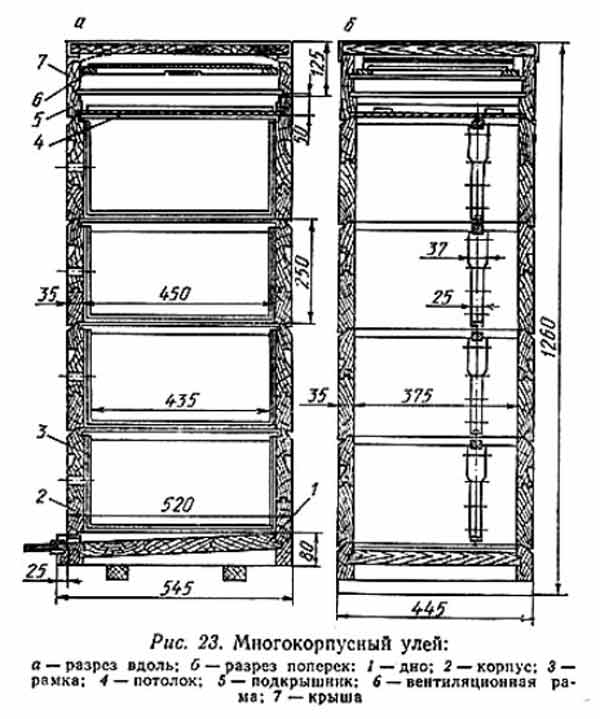

Below is a drawing with a cut along and across the frames:

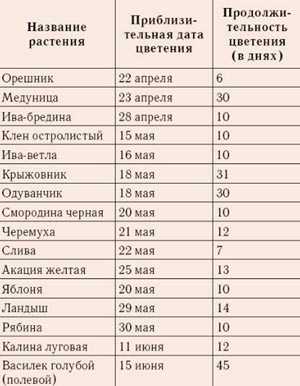

Internal dimensions of the cases (mm / cm):

- 450/45

- 375/37,5

- 250/25.

At the top and bottom, folds are selected along all the walls, allowing you to connect the structure together. Dimensions: 1,8 cm wide and 0,5 cm high.

Folds for hanging honeycomb frames are made only along the inner part of the end walls. Dimensions: 1,1 cm wide and 2 cm high.

External dimensions (mm / cm):

- sidewalls – 496 / 49,6 length and 250/25 height;

- front and back – 445 / 44,5 lengths and 250/25 heights.

Outside, in the upper part of the sides, a recess is made in the form of a shell. These are kind of handles that make it easier to carry structural elements.

Frame dimensions

To make nesting frames yourself, the following dimensions (mm / cm) must be taken into account:

- bar at the bottom – 415 / 41,5 lengths, 20 / 2,0 widths, 10 / 1,0 thicknesses;

- side strips – 220/22 lengths, 37 / 3,7 wide at the top and 25 / 2,5 wide at the bottom, 10 / 1,0 thick;

- bar at the top – 470/47 lengths, 25 / 2,5 widths, 20 / 2,0 thicknesses;

- hangers in the lower part of the upper bar – 10 / 1,0 thickness, 27,5 / 2,75 depth.

The ventilation frame has the following dimensions (mm / cm):

- side strips – length 470/47;

- front and back walls – 375 / 37,5 lengths;

- the thickness of the slats is 20 / 2,0.

By design, this is a strapping with a packed metal mesh having cells of no more than 3 millimeters.

It is used when transporting bee houses, as well as for enhancing ventilation or isolating insects during periods of processing agricultural land with chemicals dangerous to their lives.

Dimensions of the entrance

The lower tap hole is cut along the entire length of the front wall of the hulls. Its width is adjusted using a special slide.

The upper entrances are drilled along the front walls with a slight upward slope to avoid rain flowing in downpours. Diameter 2,5 cm. Height from the top edge of the wall 12,5 cm. Placement in the center. If necessary, the hole is closed with a sleeve.

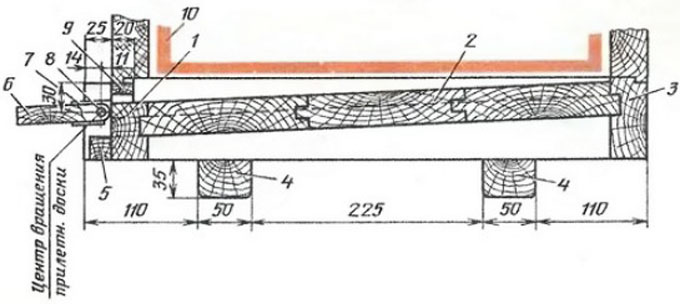

Bottom dimensions

The bottom is in the form of a flap with a slight slope from the rear rail to the front rail (1:23).

It is a detachable element that can be easily replaced when needed. There is a ledge in front, to which a folding arrival board is attached by means of hinges. Along the perimeter of the shield boards, they are edged with a strapping. The thickness of the boards is the same as that of the body – 3,5 cm.

Dimensions including strapping (mm / cm):

- 445 / 44,5 wide;

- 520/52 lengths;

- legs made of bars – 50 / 5,0 wide, 35 / 3,5 heights;

- insert for adjusting (resizing) the tap hole – 20 by 20 mm.

Ceiling, liner, cover

The roof of multihull structures is flattened to facilitate tiering during transportation. From above, the lid is trimmed with tin.

Dimensions (mm / cm):

- plank strapping – 105 / 10,5 width, 24 / 2,4 thickness;

- shield – boards 2 cm thick;

- rebate on the lower part of the walls – 15 / 1,5 depth (for installation without a liner).

Liner dimensions:

- outside – 520 by 445;

- from the inside – 450 by 375 millimeters.

Ceiling – 490 by 400 by 10 (49 * 40 * 1,0 cm).

Acceptable errors

Failure to comply with the dimensions of the multi-body hive during assembly is a gross mistake! For example, exceeding the gap between the wall and the side frame leads to the construction of honeycombs here, and its reduction causes the gap to be sealed with propolis.

Permissible deviations from the scheme:

- small parts – no more than 0,5 mm;

- large elements – no more than 1,5 mm.

The gap formed above the bars of the honeycomb frames, subject to the assembly scheme, makes it easy to install each subsequent body – the bees remain intact during the expansion work.

Conclusion

As practice shows, multi-body designs are easy to use. Whole bodies can be manipulated when forming new nests, expanding them, pumping out commercial honey.

Colonies gain strength by the time the flow begins and are more productive than other hive designs. But at the same time, practical skills and strict adherence to the terms of nest expansion are required from the beekeeper.

More about keeping technology: Multi-hive hives – secrets of keeping bees