Beeswax is a natural beekeeping product containing about 300 nutrients. It is used in folk medicine, in the cosmetic industry, and in other fields. Beekeepers engaged in the processing of bee products have the opportunity to obtain foundation on their own using a special device. The design is easy to do with your own hands.

It will work just as well as the finished one bought in the store. In modern beekeeping practice, different types of wax melting devices are used. One of the most demanded is a solar wax melting pot, made according to drawings by hand.

Principle of operation

The work of a home-made device is based on heating the raw material to the melting point with minimal costs and quick results. The solar wax melter uses the resources of the sun. This method is more profitable than using steam and furnace devices. It is practical, does not require energy consumption to obtain valuable environmentally friendly raw materials. In the solar wax melter, it is rational to process only high quality raw materials:

- residues of wax;

- ready-made honeycombs on frames from a beehive;

- water-wax emulsion.

The equipment is made from various materials, the most effective type is glass.

Helpful information!

One bee colony gives up to 7 kg of honeycomb wax per year.

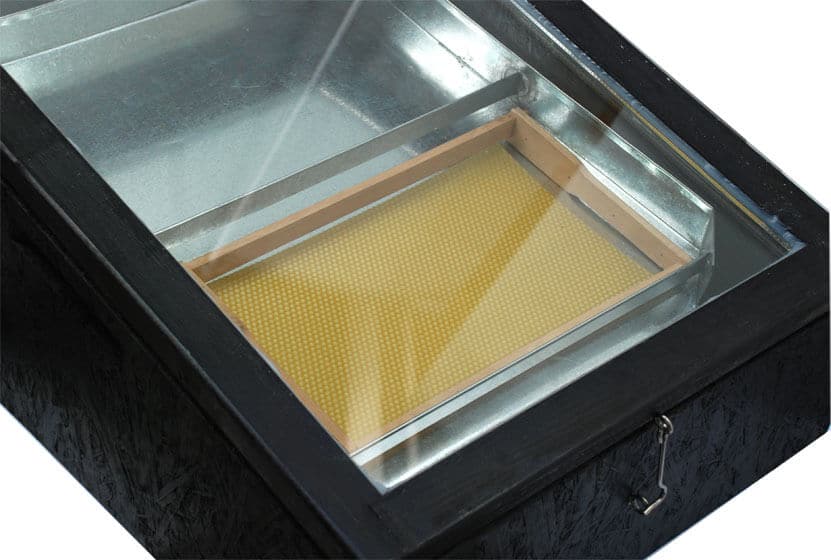

To ensure the required temperature, the device, painted black, is installed in an open place, accessible to direct sunlight. Melting is carried out in summer on clear weather days. The honeycomb removed from honey is placed under a glass surface, which heats up to 75-85 degrees under the influence of sunlight on hot sunny days. The air temperature under the glass rises to the point where the wax melts.

The pure product in liquid form begins to flow down the sloping surface into a special tray for collecting raw materials, and the darkened old honeycomb interspersed with fragments of pollen and cocoons lingers on the wire mesh. The grate can be easily cleaned of filtered residues, after which the appliance is ready for use again.

How to make a solar wax melter at home

The design of the device is simple, compact, and mobile. It can be made from materials at hand. Using a rod, the device is placed on a cross-piece placed on a support. This ensures that the module rotates in accordance with the direction of the sun’s rays and maintains the desired temperature regime.

Tools and materials

For the hand-made manufacture of a solar wax melter, you will need improvised materials and tools that almost every craftsman has:

- saw;

- a hammer;

- screwdriver or screwdriver;

- nails, screws, screws;

- boards;

- plywood.

Advice!

It is recommended to dull the nails slightly to avoid cracking the board. You can just hit the edge with a hammer.

Often, beekeepers use worn-out window frames made of wood or parts of old furniture for the manufacture of a wax pot.

Drawing

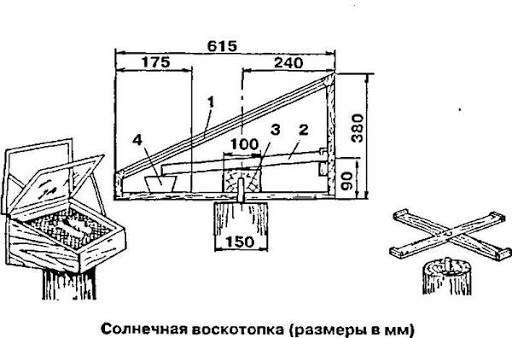

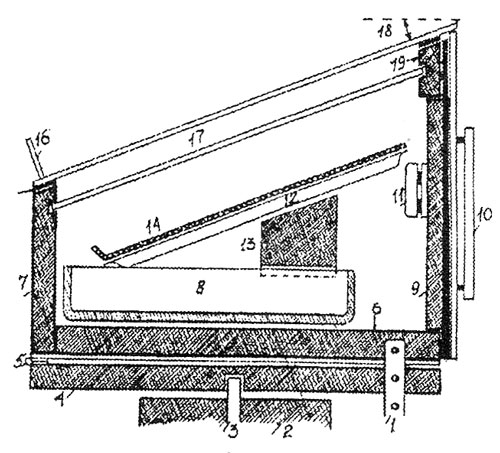

1 – metal support plate; 2 – support; 3 – metal rod; 4 – support board-shield; 5 – window hinges; 6 – bottom with insulation; 7 – wooden case; 8 – trough; 9 – detachable and attached wall-door; 10 – handle; 11 – magnetic latch-lock; 12 – tray; 13 – bar for adjusting the angle of inclination of the tray; 14 – mesh drainage; 15 – cloth sealant; 16 – control rod; 17 – ceiling with glazed air thermal insulator; 18 – angle of inclination of glass and tray; 19 – upper rear jumper bar.

Before creating a homemade device, you must complete its scheme in accordance with the dimensions of the wax baking sheet and the container for the finished product. Therefore, first they acquire or make do-it-yourself basic containers. Based on their parameters, the dimensions of the case are determined. Details for the wax melter are carefully measured so that there are no gaps and cracks in it. Otherwise, there will be losses of useful substances.

The structure consists of the following main parts:

- wooden case;

- glass frame;

- pallet for raw materials;

- tray for the finished product.

After selecting all the parts in accordance with the drawing, you can start working.

Instruction for manufacturing

To create a rectangular frame, take boards of the required size with a thickness of 12 mm.

- To increase the angle of the sun’s rays, we build up the longer side with another board of the same width. The wax melting device will rest on it.

- The bottom is made of plywood and reinforced from below, leaving a small gap. It is covered with a sturdier board for better stability of the tray.

- To install the pallet, two slats are nailed to the plywood bottom. The prepared parts are connected with nails or screws.

- A thin strip fixed in the corner of the bottom will give stability and stability to the horizontal position of the tray.

- On the sides of the case, 2 corners are fixed with screws to avoid involuntary movement of the wax container.

- The resulting frame is covered with a piece of glass, and a hinged lid is attached with the help of hinges. At the final stage, set: a baking sheet for placing honeycombs; tray for melted pure high-grade wax (“kapanets”); wire mesh for filtering raw materials.

The resulting structure is installed on a crosspiece and a stand.

Important!

When installing and working with the wax melter, you must comply with safety requirements.

Using

Ready-made industrial wax melters are usually used in large beekeeping farms. There, raw materials are processed on a large scale. Homemade devices are suitable for processing a limited amount of wax in small apiaries. They allow you to minimize the cost of their manufacture and modernize the design.

When examining an apiary, the beekeeper:

- removes wax build-ups on the tops of honeycombs;

- cuts off protruding parts;

- rejects used and damaged frames.

The convenience of using a solar wax melter in an apiary is that the raw materials do not need to be stored for a long time. While waiting for processing, a moth may start in it.

Often, beekeepers use a device to melt dry directly within the frame: it is placed in the unit without cutting out the wax. It is completely thawed out, and the frame is disinfected under the influence of sunlight and high temperature.

Pros and cons of solar wax melter

Creating a device from drawings is easy for the wizard. It only takes a few hours. A productive unit melts from 3 to 4 kg of wax per day – it processes raw materials obtained from 4-5 dozen bee colonies. It provides high quality, environmentally friendly products. Its advantages:

- structural reliability;

- high performance;

- lack of impurities in the resulting product;

- ease of maintenance;

- free use of solar energy;

- melting immediately after receiving the raw material.

The solar wax melter has very few disadvantages:

- the seasonal nature of the operation of the device;

- conditionality by weather and climatic conditions;

- waste residues from the processing of old honeycombs;

- systematic cleaning of the pallet and wire mesh from waste.

A valuable beekeeping product – wax – beekeepers can get using a simple homemade device. The solar wax melter, which uses free energy, helps to obtain an environmentally friendly, high-quality product.