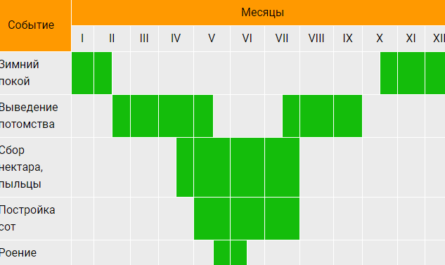

The need to transport heavy inhabited hives is due to the move of the apiary or seasonal work carried out on it. For example, bee houses must be taken out of the winter house in the spring for the insects to fly for the first time. Or the apiary will have to go in the summer to migrate. In the fall, again, we will be settling in the winter quarters. Also, the apiary cart is indispensable for pavilion beekeeping – with its help feeders are delivered. In autumn, this is about two three-liter containers for each family. And on small carts you can transport honey frames.

Another important device is the scales, which are used by the beekeeper to control the development of bee colonies. They can also be assembled by hand.

The content of the article

- 1 Cart classification

- 2 Homemade apilift

- 3 Homemade cart

- 4 Homemade scales

Cart classification

By design features, they are distinguished:

- ladders and carts proper for working with them;

- lifts or apilifts.

Working with a ladder is as follows. A ladder welded from corners is attached to the truck.

The dimensions of the ladder must correspond to the trolley so that it does not slip down when loaded.

Loading is done like this:

The first stage.

The second stage.

The third stage.

The fourth stage.

When loading in this way, maneuverability plays a decisive role – the trolley must move easily inside the truck body. This can be achieved by improving its design.

In principle, loading work can be handled independently if the cart is built on the principle of a lever – there are no additional handles or structural bends in it. Such a “lever” is convenient to use both horizontally and vertically.

In this case, it is important that the axis (support) is as low as possible, that is, closer to ground level. The height of the entire cart is approximately up to the shoulder level of a loader.

Important: It’s better not to be too zealous with the length of the handles, since the elongated version reduces maneuverability. But at the same time, they should be straight and long enough for ease of use.

An inclined platform with steps that allow the loader to rest is used as a ladder. Many beekeepers give preference to just such a loading, deliberately refusing to use the lift.

And this is the very way of loading onto a car body or a trailer. A lever (that is, a straight-line design) facilitates the passage of each step. The essence of the steps is to give rest to the muscles of a person. After all, it is the fatigue of the beekeeper that makes it difficult to rearrange the hives.

Working with a trolley with curved handles and a classic ladder without steps. But it is worth noting that the weight of the bee houses in this example is small and the height to the trailer platform is also small.

The second loading option is the use of an uplift. This is quite expensive equipment, which determines the independent manufacture of such a modernized cart by folk craftsmen.

The universal store model has an adjustable grip, that is, you can transport different types of bee houses, barrels and other containers. But there are restrictions on the lifting height and weight of the load (usually up to 150 kg).

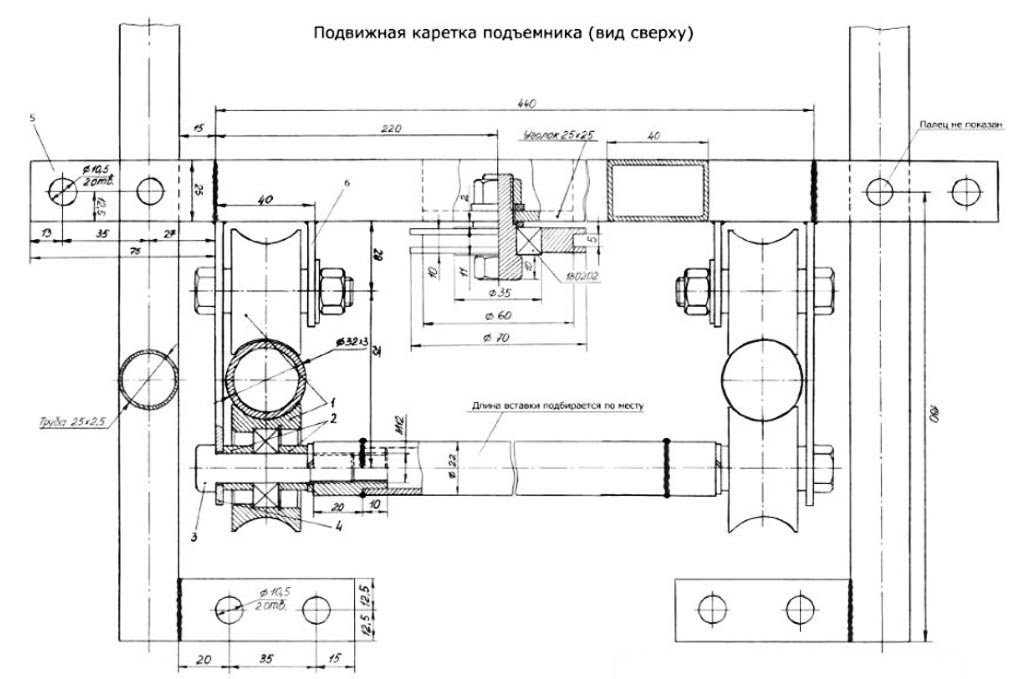

Such equipment is assembled from two frames mounted on one axle with wheels. Includes lever with cable, forks and clamp bracket. A special screw allows you to adjust the loader, adjusting it to different sized loads.

Apilift is brought to the hive. At the same time, the lever is raised up. The bracket is adjusted with a screw – the gap between the bee house and the lift should not exceed 5 mm. Then the handle is lowered – the lever tightly grips the load. The hive rises to the height by means of a winch.

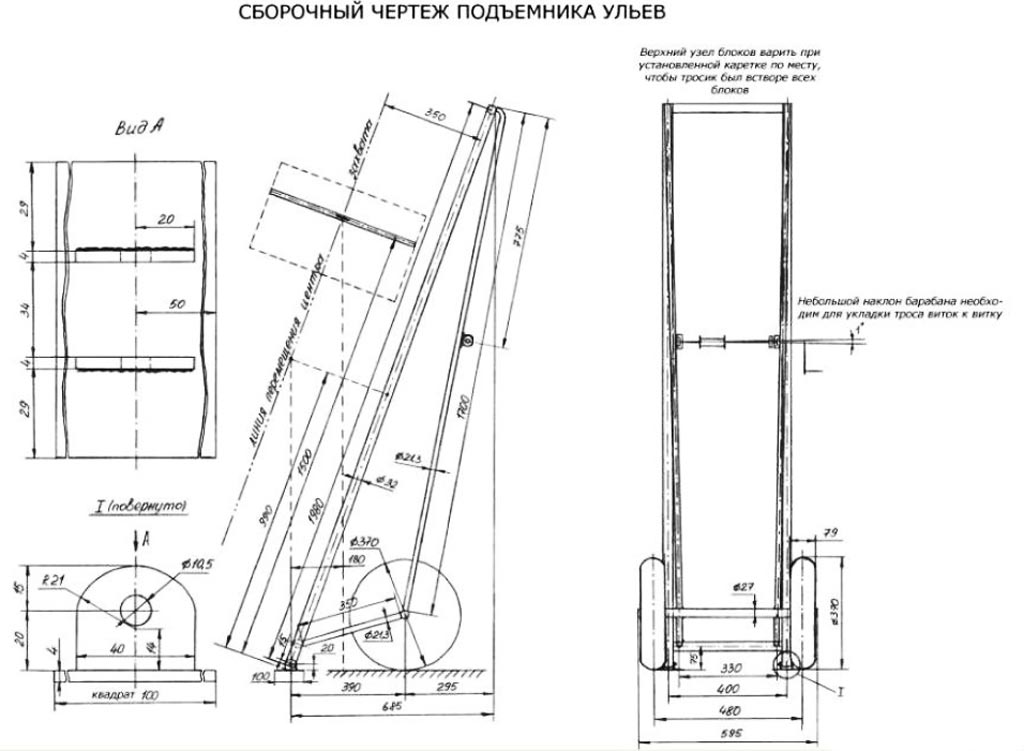

Homemade apilift

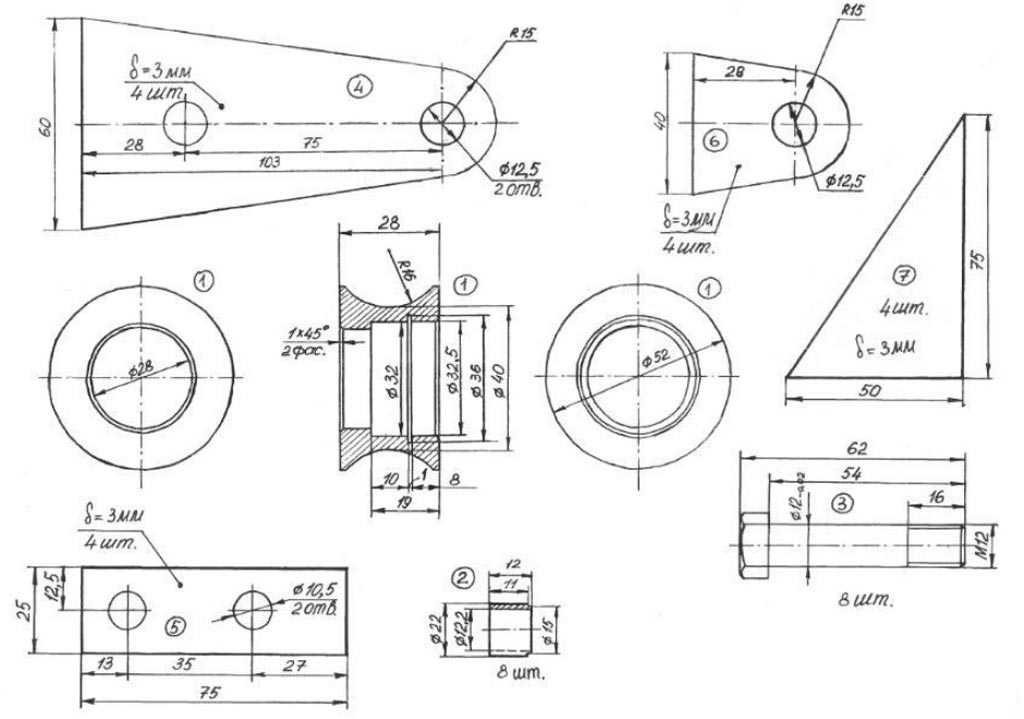

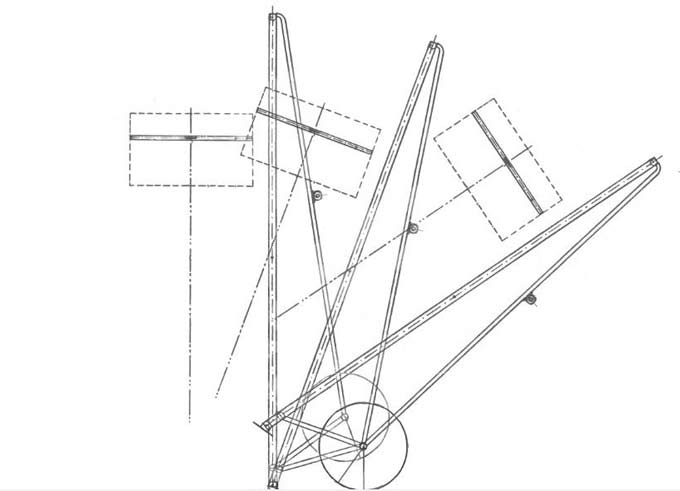

Drawings for the manufacture of the lift – the idea belongs to Igor Sidorov:

You can make such a convenient device with your own hands only if you have the appropriate experience, all the necessary tools and equipment, in particular a welding machine. The assembly is carried out in several stages: the carriage, the lifting mechanism, the frame are mounted. Installing a mechanical drive facilitates trolley control.

Another option is a homemade model with a screw handle.… It looks like this:

Assembly features:

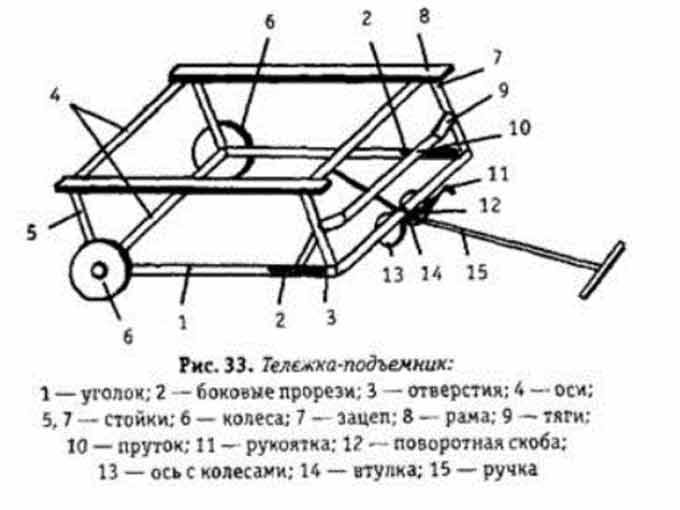

- The lower fixed frame is U-shaped. Axles equipped with strip metal posts are attached to this base.

- The movable frame is welded from corners and mounted on four separate posts.

- The rods are attached to the front risers, in turn, welded to the rod. The rod moves freely in the grooves of the lower frame (the basis of the structure).

- The front wheel axle has a hub welded to the handle. The axle is mounted on a pivot bracket in front of the handle using a bolt and a nut.

The device works simply. Rotating the handle, they achieve such a position so that the bee house is above the stand (the movable frame is at the same time lowered). Then the hive is transported, the cart is placed between the racks, and by turning the handle I set the house in a new place.

Homemade cart

Here are some ideas for making simple shopping carts.

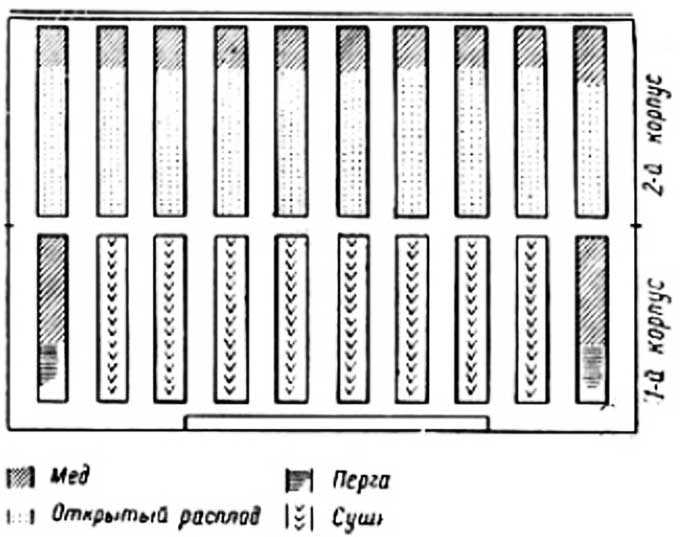

This model is suitable for transporting honey-filled four-body hives.

And this model was welded without any drawings on the basis of an old stroller, using corners and fittings. On such a structure, 16-frame hives can be transported without problems. The second model (left) is designed for transporting flasks.

Model from the tutorial. On a well-rolled road, such a structure can withstand a load of up to 300 kilograms! Unfortunately, we do not have exact instructions for assembling it.

You might be interested in: Do-it-yourself carts for transporting beehives

Homemade scales

As for weighing beehives, craftsmen also offer several design options.

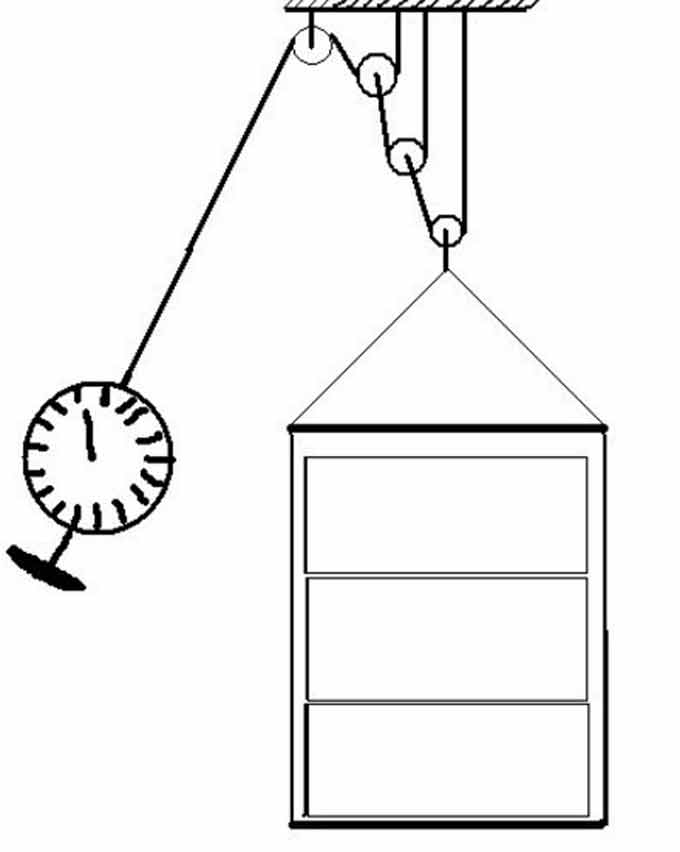

The easiest way to use a harness is assembled from blocks, steel cable and weights.

Weighing error up to 100 grams. It can be set by multiplying the accuracy of the scales by the number of blocks used.

A more difficult option is to use a strain gauge design:

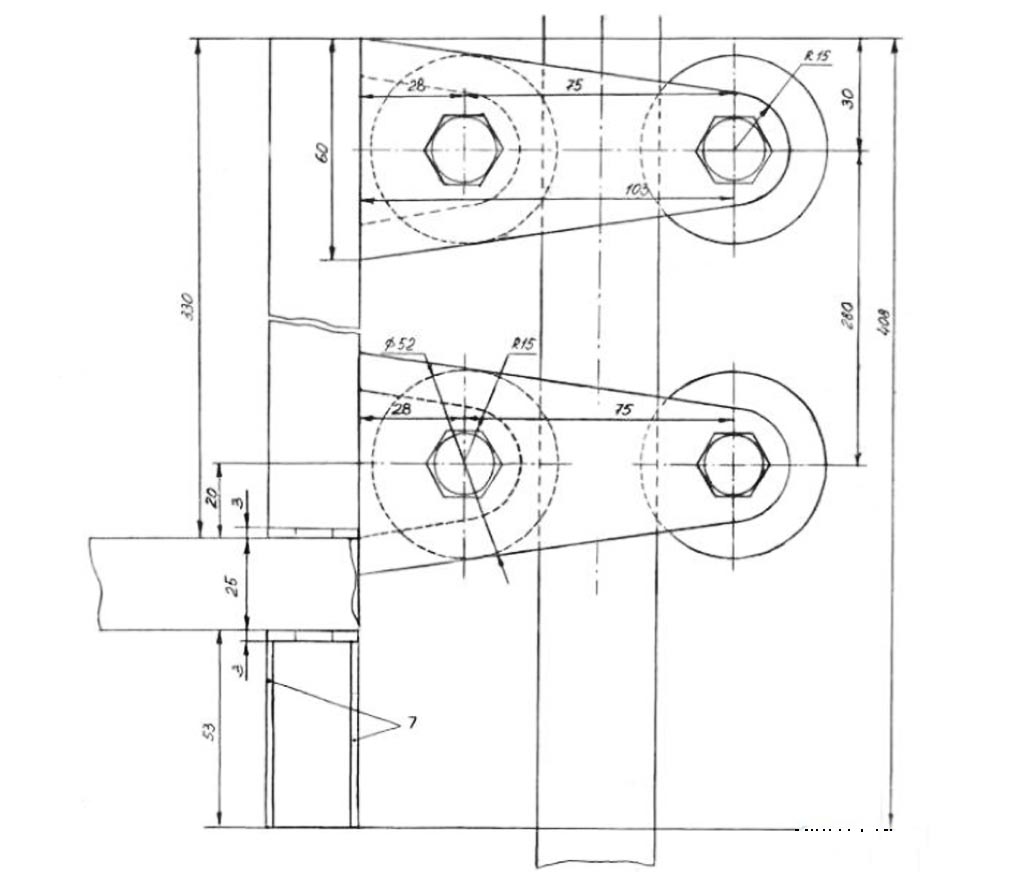

The lower part is stationary, a sensor, an electronic unit and a power button are mounted to it. The block and the button are brought out and fixed in a convenient place (in the photo this is the position in the front left). The load cell is a duralumin plate with three wires.

The upper movable part rests on the levers. It is fastened to the base with two springs.

A frame from a corner with four bearings is mounted to the base using 4 screws.

A nut is welded to the frame, into which the handle is then screwed. It can be used to raise the scale together with the lower frame by 2 centimeters.

For weighing, bars with a height of 5,5 cm are installed under the bottom of the bee house. Alternatively, they can be part of the structure of the bottom of the hive. The balance can be inserted into the gap thus obtained. Then you need to press the start button – zeros will appear on the display (auto-zero will be set). Further, by rotating the handle, the hive is lifted and weighed. Then the handle rotates in the opposite direction – the scales get rid of the load.

All bearings work synchronously – it is impossible to drop a hive with a flat bottom. A rise of 2 cm is carried out in twenty turns of the handle.

The basis of the design is an ordinary Chinese scale in a metal case, equipped with one load cell (glass models have four sensors – they are not suitable), 340 mm wide. For example, a model like this would work:

With the help of these self-made apiary scales, assembled by yourself, you can weigh all the hives at the point one by one and write the results obtained in a separate table. As a result, knowing the weight of empty bee houses, it is possible to accurately determine the weight of bees and collected honey.

It should be noted that beekeepers dislike electronic scales precisely because of the need to go to the autoloader. That is, the balance must be unloaded at the start of weighing. However, in the presented self-made model, this problem is solved literally by turning the lever, which is quite convenient in practice.