In industrial beekeeping, dividing grids are an indispensable element of hives, without which the withdrawal of breeding queens and the organization of honey collection cannot do. Similarly, this equipment is used in amateur apiaries.

The author’s idea for the creation of the first lattice belongs to François Hubert. It was also used by the Ukrainian beekeeper Prokopovich. And with the light hand of Ghaniman, a beekeeper from Brazil, the invention began to be used all over the world.

The content of the article

- 1 Role in the hive

- 2 Of what do

- 3 dimensions

- 4 Correct installation

- 5 Product care

- 6 How to make yourself

- 7 What is used for?

- 7.1 Difficulties in use

- 8 How to use in multi-body systems

- 9 How to use in sun loungers

- 10 How to use in double hull systems

Role in the hive

Long-term observations of the life of bees have allowed research beekeepers to discover an important feature of insects – honey storage cells, regardless of whether they are bee or drone, will be placed in a nest above the perga and brood zone. Honey cells in any hive are most observed in the upper corners of the honeycomb frames.

This natural instinct of the bee colonies is successfully used to produce honeycombs filled exclusively with honey. That in the future facilitates its pumping out – young growth is not destroyed, the product is obtained without foreign impurities.

When setting up several enclosures or store extensions, separated by a bee space that never deals with combs, strong colonies will always store their honey stocks above the brood nest.

By using, in addition to such vertical division, the installation of a dividing grid, an effective limitation of brood is obtained in the hive – the uterus no longer penetrates into the upper body sections, and the honey cells remain clean from laying eggs and ready for honey collection.

Of what do

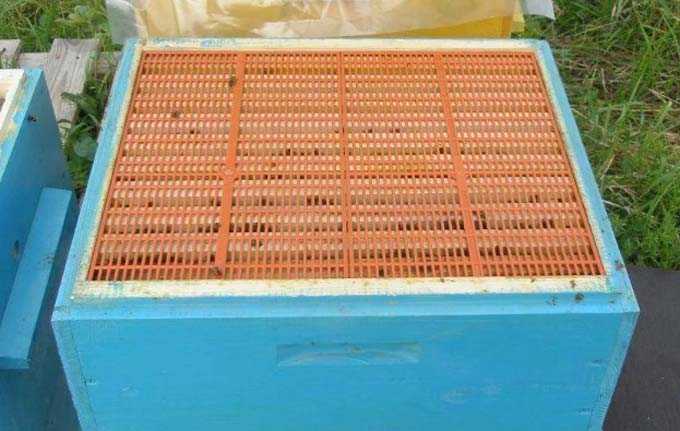

The grilles are manufactured in three versions:

- from perforated metal plates – an outdated option that can only be found in apiaries with old equipment;

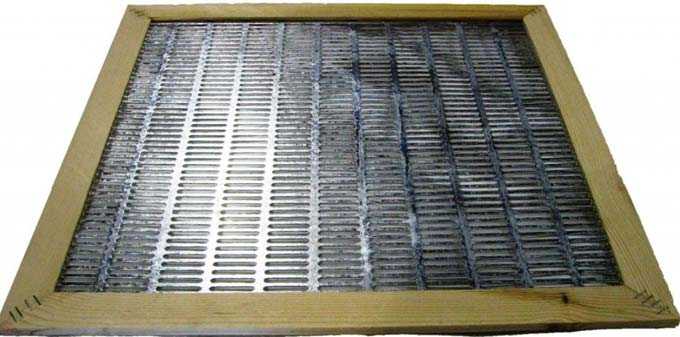

- made of wire – the most practical and safe products for bees, despite the considerable age of the invention;

- from polymers – a modern version of inventory, most often found on the market and actively advertised in stores.

dimensions

The design of the lattices is based on the size difference between the members of the bee colony. Queens and drones are always larger than worker bees. To keep them in a certain area of the nest, it is necessary to install a separator with lattice holes from 4,1 to 4,5 mm – these are the dimensions that manufacturers adhere to.

The lattice does not interfere with the free passage of worker insects into the brood zone – life in the nest proceeds naturally without any changes or disturbances in its development.

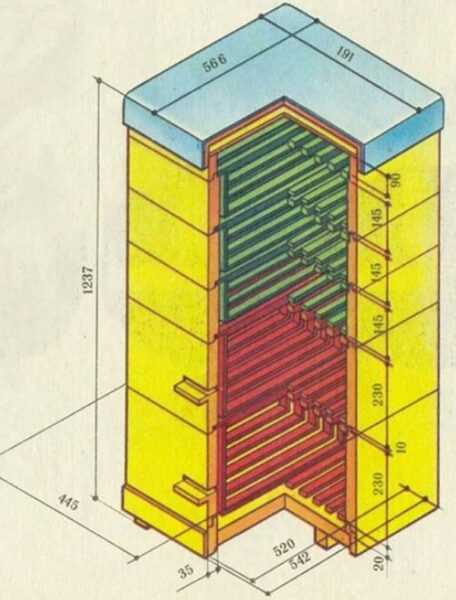

Modern lattices have collapsible mechanisms that allow you to adjust the dimensions to the dimensions of the hive body. The external dimensions of the product of the universal sample are 448 by 432 mm.

Correct installation

Lay the lattice in such a way that its slots are along the streets!

In 12-frame Dadans, the length of the universal product coincides with the dimensions of the hive, and the width of the structure needs to be slightly moved apart, leaving a small gap of about 2,5-3 mm. Likewise, the separator is installed in multi-body systems.

The dividing lattice for 10 frame hive fits close to the walls of the case – there are no gaps between the two parts of the product, but first it must be broken off along the seam. You can purchase a special model for this type of hives with dimensions of 420 x 495 mm, made of plastic. It costs about 150 rubles.

But the most important thing during installation is to maintain free space above the frames for the passage of bees. This distance is about 0,8 cm. If it is not there, the bees glue the lattice with propolis to the bars – the separator is deformed when removed and stops working to restrict the uterus.

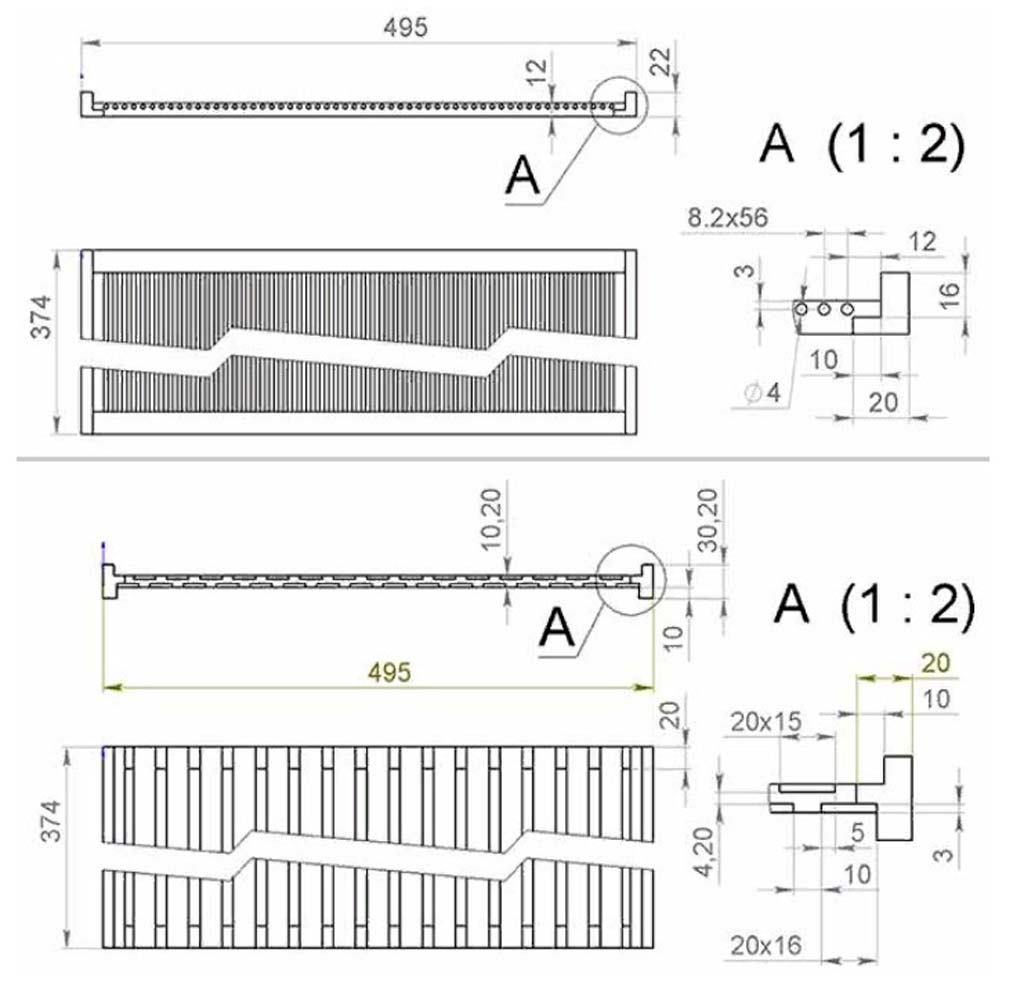

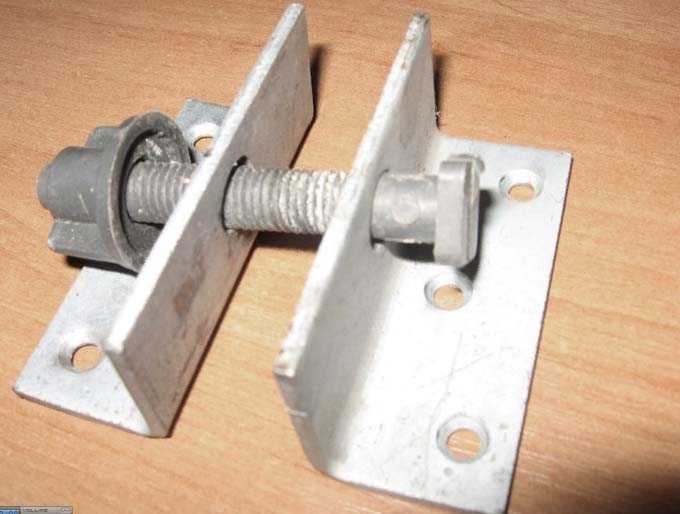

To solve this problem, a strapping is made for the hive dividing grid. Any suitable material can be used – wood (slats, bars), metal or plastic strips 3 mm wide.

Lattice thickness 3 mm. When making a strapping from wood, folds are selected on the blanks for this size. The finished strapping height is about 24 mm. There are folds along the outer perimeter for the installation of the body sections. The length and width are selected in accordance with the dimensions of the hive.

The harness is assembled using self-tapping screws. Holes are pre-drilled in the grate and small nails are hammered. They do not need to be cut, but folded on the opposite side so that the grill is held securely.

Product care

During operation, the gratings are covered with wax and propolis. A hairdryer is used to cleanse them. The products are removed from the hives, laid on paper and gently warmed up – the wax flows down.

The method of cleaning with a hairdryer is not applied to thin plastic models due to possible deformation! It is necessary to roll them up and take them out into the cold. At low temperatures, wax and propolis become brittle, which facilitates quick cleansing.

With the correct installation, there will be no excess wax on the gratings, since the bees will not begin to build up the bridges between the body sections. Correct installation means:

- observance of the bee space between the bodies (the distance between the top and bottom of the frames in adjacent sections) is 0,8-1 cm;

- as well as installation by holes along the streets.

How to make yourself

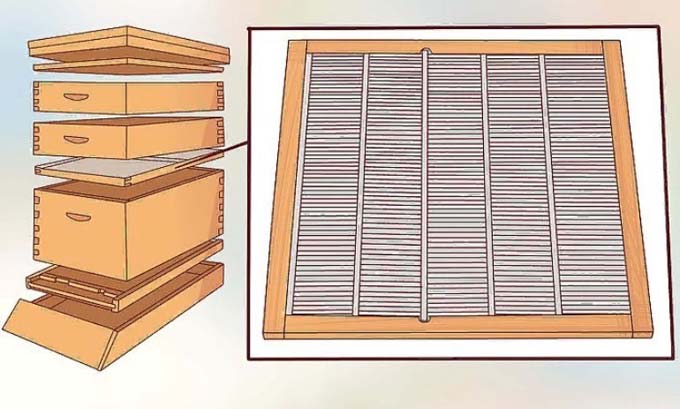

Below is a drawing for DIY manufacturing:

For work you will need:

- a coil of thick wire or metal rods;

- boards for making strapping;

- carpentry tools;

- nails and rivets for assembly.

On the finished frame, markings are made for rods or wire in increments from 4,1 to 4,5 mm. Then the rods are fixed with nails or rivets (more convenient to use).

Alternatively, the workpieces can be welded with a welding machine onto a pre-prepared strapping from a metal corner.

What is used for?

In modern beekeeping, this equipment is used:

- to hatch larvae of the same age;

- to separate the brood and honey zone of the hive during honey collection;

- to obtain high-quality comb honey;

- to hatch a new queen bee while preserving the old one for this period (the grafting frame is installed behind the separator);

- for double-queen keeping of bee colonies;

- for the production of royal jelly;

- for planting a swarm (the lattice is installed on the entrance for catching queens).

Difficulties in use

With careless and improper use, wire products can be deformed, and made of plastic can break.

Metal models made from plates have sharp edges of the holes, which injure the worker bees – insects damage the legs and wings.

In addition, there are plastic grilles on the market with exactly the same disadvantage!

It is necessary to purchase one product and test it in practice. In this way, it is easy to select a suitable manufacturer. High-quality plastic should not break easily. It bends well, has no sharp cuts along the edges and in the cells.

How to use in multi-body systems

The grille allows:

Contain two queens. To do this, the hive is divided into two sections – in the upper one lives a layering with a young “queen”, who requires a mating flight, and in the lower one, an old uterus is working. After mating of a young female, the lattice is removed, while the old uterus is removed – the families are united at the beginning of the honey collection.

Fight the swarm instinct… For this, the upper entrances are closed, all queen cells are cut out, and the working queen, together with the open brood, is isolated in the lower body.

Lattices in multi-hull systems help out beekeepers with meager bribes and a poor honey base, allowing them to control the brood zone and storage of bee bread.

To read:

Breeding a home apiary with swarms

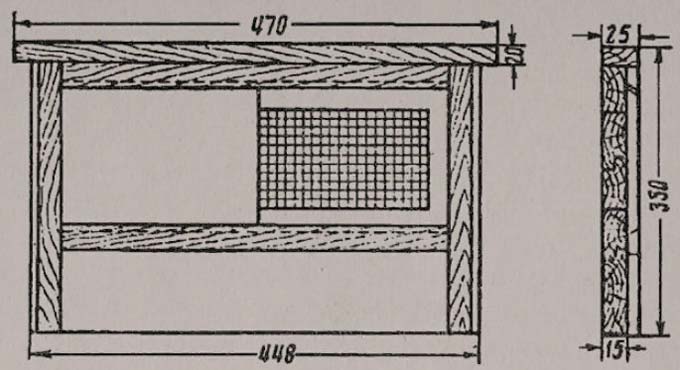

How to use in sun loungers

In horizontal hives, the uterus also has the habit of moving around the nest, sowing in the most inappropriate places for the beekeeper. As a result, it is almost impossible to obtain pure marketable honey!

During periods of bribe, the “queen” is limited to four brood honeycombs – the nest is divided into two sections with separate entrances.

Moreover, the lattice itself, based on beekeeping experience, must have a special design. This is a blind diaphragm with rubber seals around the perimeter, equipped with a barred window in the center.

A canvas is attached to the divider from above with a stapler so that the bees do not build honeycombs here. After the end of the bribe and the pumping of honey, the lap is removed from the mounts – the separator is removed from the nest.

How to use in double hull systems

By double-hull systems are meant 12-frame Dadant-Blatt hives, equipped with two hives or one hull with two magazines.

The use of a dividing grid in double-hulled hives allows you to obtain pure marketable honey, including honeycomb. For this, the nest is separated from the magazine extensions.

The holes located above the level of the divider are kept open (except in cases of swarming!) So that the bees themselves choose a more convenient path and do not pass through the holes of the lattice again.