The acquisition of new hives when expanding the apiary is one of the most tangible expenses for the family budget. It is not surprising that many beekeepers strive to produce bee houses with their own hands.

In this case, a high-quality woodworking machine for making beehives will help to facilitate the task. The Internet offers many options for such equipment, mounted at home, often from scrap materials. For more discerning owners who can afford a factory model, the compact machines of the Belmash company are suitable.

The content of the article

- 1 Where to choose

- 2 Factory-made machines

- 2.1 Technical specifications

- 2.2 Possibilities and features of operation

- 3 Homemade machines

Where to choose

If this is your first time choosing a machine for your home workshop, pay attention to the following points:

- The technical characteristics and capabilities of the equipment – the maximum length available for workpieces, depth of holes when drilling, width and depth of planing.

- The type of bed – the cost of the machine will directly depend on it. Cast bed models are more suitable for machining large parts. Accordingly, they are more expensive, as they are intended for large-scale production. But equipment with a welded bed was originally designed for small or medium-sized workshops – its price is relatively low. Medium-sized workpieces can be processed on such a machine.

- The assortment on the market. The more models a manufacturer has, the easier it is to make a choice when buying.

Factory-made machines

As an example of a universal woodworking machine, we will consider the Master-Universal 2 500E.

This is a compact unit that successfully performs several functions: sawing wood up and down, planing workpieces, drilling, milling. It is equipped with an electronic unit that is able to start the equipment even when the voltage in the mains drops (admissible minimum 160 volts). A special adapter is responsible for removing the chips.

The package includes a temperature switch, a ruler, two knives, a saw and planer table, spare parts for right angle sawing. Also, the product is supplied with personal protective equipment – glasses and a mask.

Additionally, you can purchase from the same manufacturer:

- thicknessing attachment;

- a clamping device that facilitates planing;

- work table complete with adjustable legs.

The price is about 20 rubles. On the secondary market from 000 rubles. The machine is certified according to GOST. The manufacturer gives a one-year warranty on it.

Technical specifications

When assembled, the machine weighs 61 kilograms, which allows it to be easily transported or moved within the workshop.

An asynchronous motor with a capacity of 2 watts, protected from overheating and adapted to start at an underestimated voltage in the mains. The maximum number of revolutions is 500 per minute. There is an emergency shutdown – in case of malfunctions, the machine can be stopped in a matter of seconds.

A stop with a scale helps to lay the workpiece on the table at the desired angle, which allows for high machining accuracy. The stability of the equipment is ensured by dampers on the support legs and a wide base.

Other important features:

- knife width 250 mm;

- saw blade thickness 1,8 mm;

- cutting depth up to 100 mm;

- the smallest slice height is 3,5 mm;

- dimensions of the milling table – 370 x 200 mm;

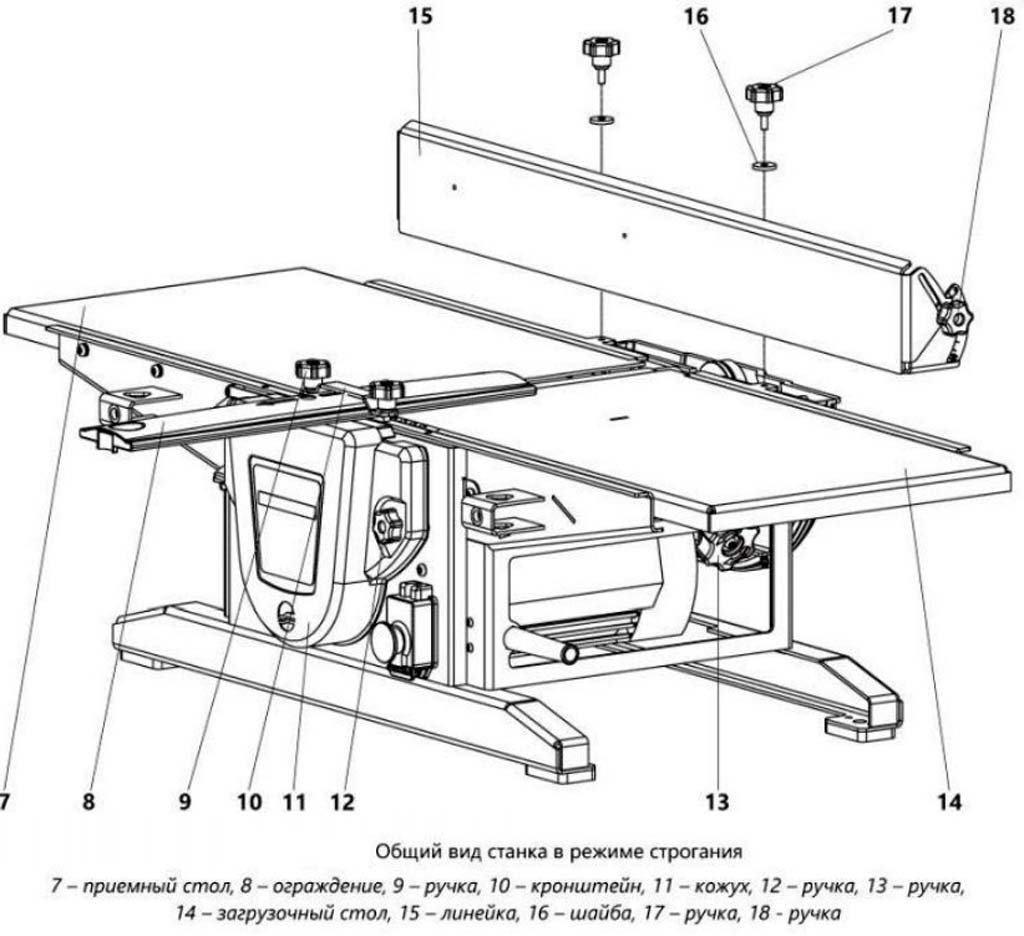

- planing table dimensions – 882 by 318 mm;

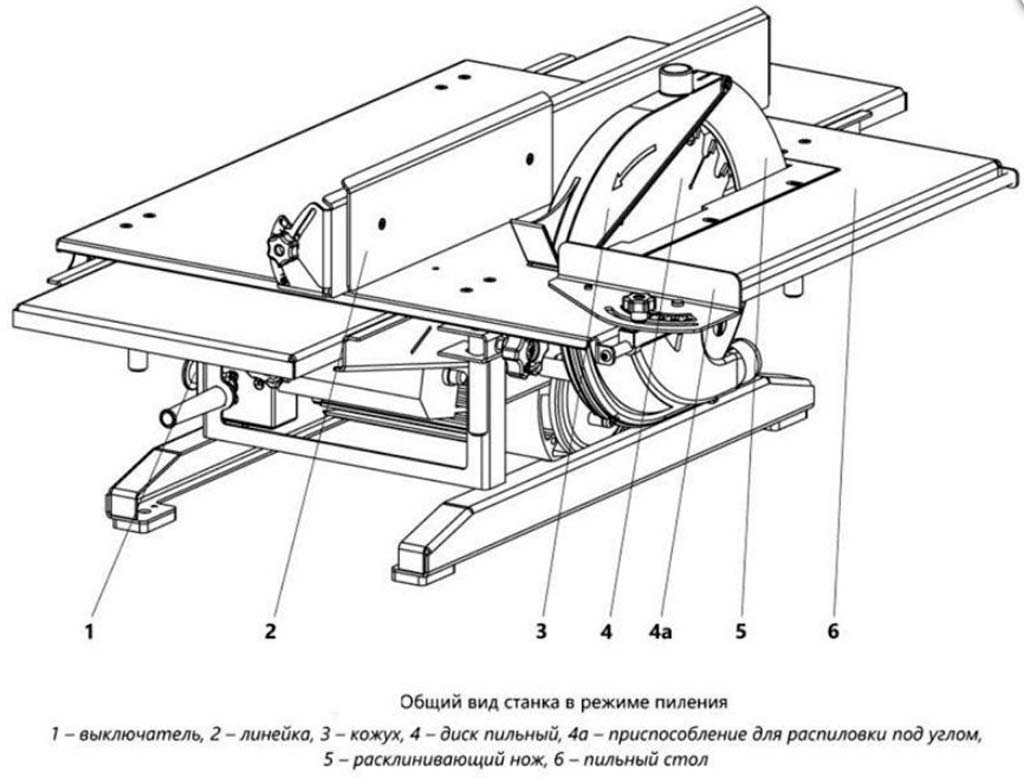

- sawing table dimensions – 750 x 510 mm.

Possibilities and features of operation

The specified model is the most powerful in its line. It is intended primarily for domestic use. It is connected to a single-phase power supply. The power supply must be protected with a 16 amp rating.

According to home craftsmen, the machine does an excellent job of sampling quarters, which facilitates the production of hives.

You can saw boards both across and along the wood fibers. For rip sawing, there is a special guide fence that allows you to precisely set a certain depth.

Planing of three types is available: along the edges, at an angle, along the edges. For the convenience of performing this operation, the unit is equipped with a clamping device.

A separate table is intended for sawing a wide overhead, which is installed, if necessary, above the planer plane. The sawing plane is easily adjustable in height – it is easier for the master to control the protrusion of the saw above the plane of the workpiece, which allows cutting even sheet materials.

Machine overview:

Reviews of this model are controversial. There are complaints about the unreliability of the bed, overheating of the engine. On the other hand, this is one of the budget options available at a price to novice beekeepers.

For some craftsmen, judging by the same reviews on the Internet, the machine worked without problems for 4 to 8 years. They emphasize that a lot depends on the person who works with the equipment. In some cases, the unit is operated for an eight-hour working day without overheating of the electric motor and other problems.

Homemade machines

As noted above, the Internet is replete with video reviews of homemade woodworking machines. Many of them are universal in their technical capabilities.

Below are vivid examples of such equipment.

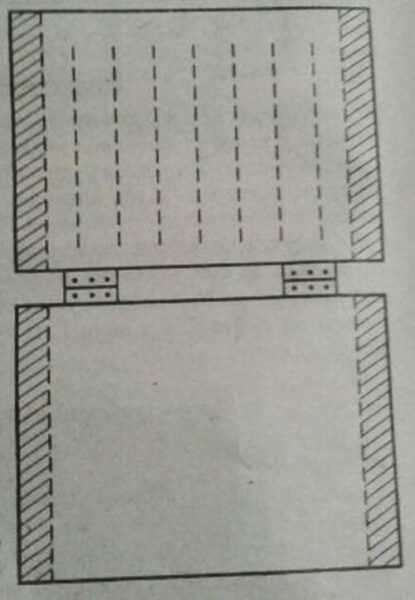

Here the master emphasizes that he uses cutters for metal. The smaller one is suitable for sawing folds intended for setting frames in the hive. A large one with a width of 12 mm is used for sawing external grooves, on which a body or a liner is then placed.

In this video, the master explains in detail what tools he uses in the manufacture of bee hives. And he also describes his homemade machine – the most important, in his words, the equipment in the home workshop.

The unit is designed for four operations: planing, sawing, milling and using a planer to fit the workpiece to the desired size.

Which model – factory or homemade – you choose will depend on your financial capabilities. Many home-made samples of this equipment are practically in no way inferior to machines assembled at the factory.

You can watch video reviews of other homemade mechanisms used by beekeepers here: Homemade woodworking machine for frames