The hive system by professional French beekeeper Roger Delon was released in 1979 and marketed as the Climatstable or Alpine hive. The system came to our country thanks to Yaroslav Batsice, a resident of the mountain village of Rozhev, Lviv region, who got acquainted with the novelty of beekeeping in the world French magazine La Gazette Apicolle.

The design is based on the natural habitat of honey bees – a tree hollow. Therefore, the hive is noticeably narrower than the traditional multi-hull, and the shape of its frame has an original solution.

The content of the article

- 1 Design features and dimensions

- 1.1 Advantages

- 2 DIY assembly

- 3 Domestic modernization – Khomich

- 4 Features of beekeeping

- 4.1 Change of uterus

- 5 In conclusion

Design features and dimensions

The hive belongs to the multi-body small-format type – the horizontal section of the bee nest is noticeably wider than its vertical size. The club for the winter will be formed in much the same way as in the wild, which is considered a plus of the design.

To read:

Small format hives

The dimensions of the alpine hive proposed by Delon are as follows (in mm):

- 300 – width;

- 300 – length;

- 215 – height.

All walls are 30 mm thick. The entrance slot is available only in the lower housing. In front of it there is an original inclined arrival board.

The system is completely devoid of ventilation holes and dividing grilles. The movement of air inside the dwelling occurs naturally. Getting through the entrance, cool air gradually warms up, saturated with carbon dioxide and moisture. Having reached the ceiling, he slowly returns down and goes out.

There is a feeder in the ceiling, which plays the role of air insulation. Thanks to this design, condensation does not form on the ceiling. The cover is flat, equal in thickness to all other elements of the hive.

During the active period of honey collection, the system is expanded by installing additional buildings. The maximum construction height in summer is over 1,5 meters.

Advantages

It is known from beekeeping practice that alpine hives contribute to the rapid development and high productivity of bee colonies. It was noted that even in unfavorable years in terms of honey harvest, nectar and pollen are brought in 2-3 times more than in other hive systems. And bees build honeycombs more readily in the Alps than in the same Dadans.

The system is easy to manufacture and costs the owners cheaper than traditional hives – the wood consumption here will be half as much. In addition, the frames do not need to use expensive tin-coated wire – this design does not require additional honeycomb reinforcement.

The frames, despite their structural features, are strong enough and easily withstand pumping out in a honey extractor. And their reduced size solves the problem with honey harvest during periods of weak flow – bees manage to fill all the combs with honey and do not grow brood on the same frame.

The hive does not require any additional insulation during wintering, except for a canvas made of a polypropylene bag or oilcloth on a fabric basis.

The system is ideal for roaming. The hives are lightweight and compact. The case filled with honey weighs up to 16 kilograms, empty – 5 kg.

Roger Delon invented a special block installation during the wandering. The constructions are placed in one line, four pieces per common bottom, and covered with one large lid. This arrangement allows you to compactly place the apiary on the point, and successfully withstand strong winds.

And the convenience and ease of maintenance of these hives were proven by Roger himself. He single-handedly tended 1 bee colonies at several locations in the Alps.

DIY assembly

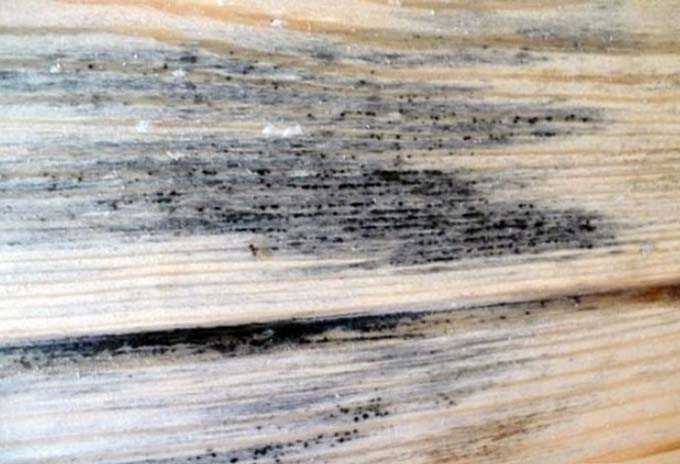

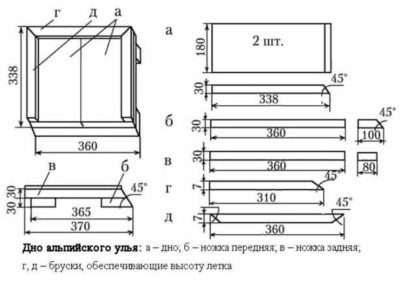

Pine non-resinous boards are suitable for making a beehive. It is recommended to soak the bottom of the alpine hive with linseed oil from the inside, and cover it with aluminum paint on the outside. In the spring, during the cleaning of the bee houses, all the bottoms are replaced with new ones – cleaned and disinfected.

The arrival board has a slope of 35 degrees. It is nailed along the front wall just in front of the slotted tap hole, measuring 300 by 7 mm. The height of the tap hole is set thanks to the trim in the form of plinths stuffed on three sides of the bottom. The bottom rests on two legs.

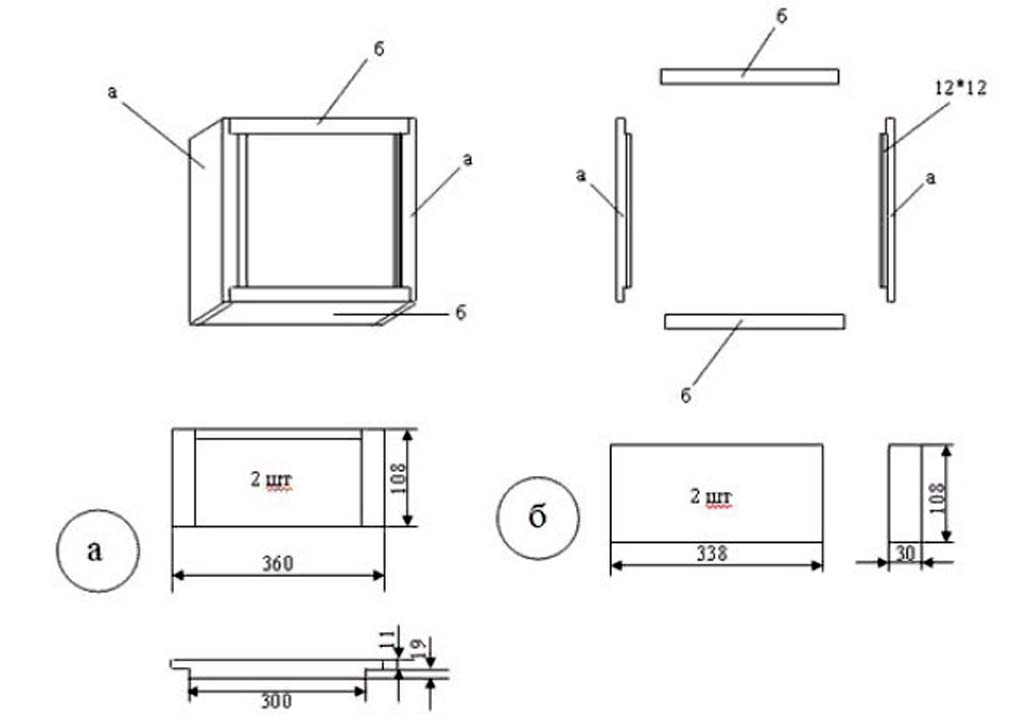

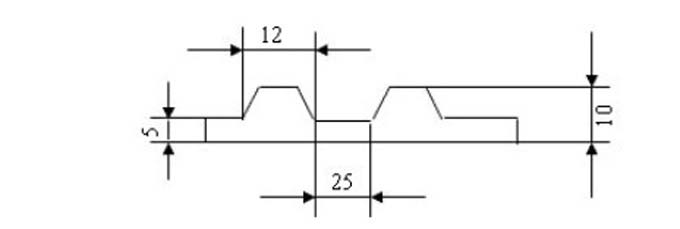

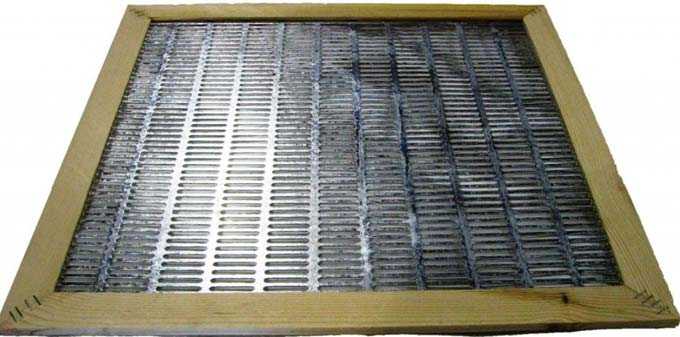

Each body section accommodates 8 honeycomb frames installed on 12 x 12 mm rebates. For the reliability of hanging the honeycomb, metal inserts-combs are placed here.

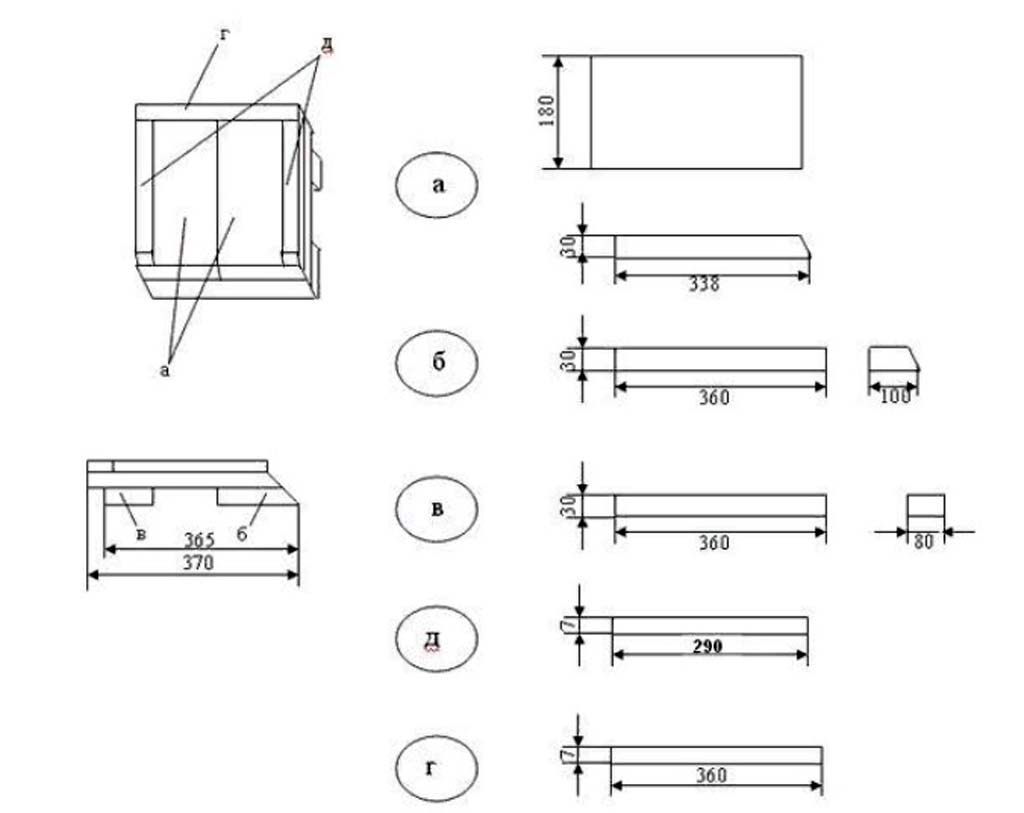

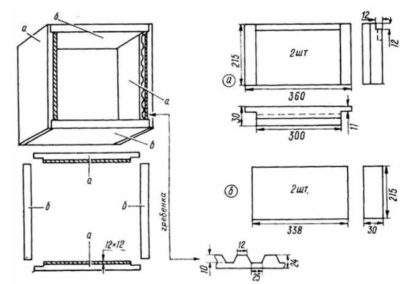

The assembly of the case is very simple. Fir or spruce boards 30 mm thick are mounted in the form of a box. Part sizes (in mm):

- 360 by 230 – 2 pieces;

- 338 for 230 – 2 pcs.

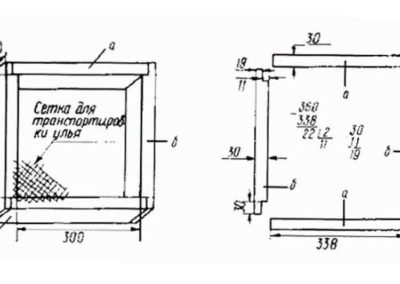

The system includes a universal cassette designed for collecting royal jelly and transporting bee colonies (complete with a net).

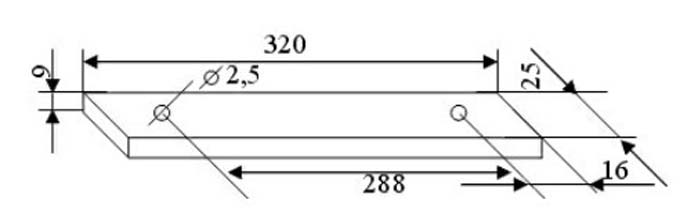

The feeder cover is knocked down from fir or spruce boards impregnated with linseed oil and 5 mm thick fiberboard sheets. From the inside, all surfaces are painted with white paint. The bottom of the trough fits into the grooves of the walls, leaving an 11 mm passage on one side. On the bottom from the side of the hive, slats are sewn to stimulate the laying of propolis. The ceiling is equipped with a small cover.

Dimensions of fiberboard parts (in mm):

- 324 by 57 – small cover;

- 320 by 295 – the bottom.

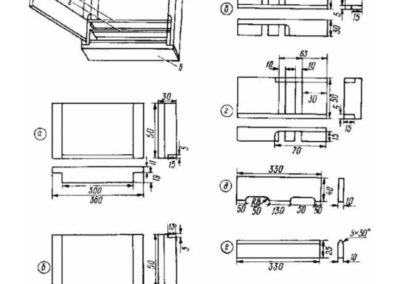

The cover is a sandwich made of two sheets of furniture board, a layer of thermal insulation material and an outer upholstery made of galvanized iron or any suitable roofing material.

Part dimensions (in mm):

- 360 by 360 – 5 mm cardboard (2 parts);

- 360 by 360 – 20 mm insulation glued on top of cardboard with moisture-resistant glue;

- 362 to 362 – roofing material.

The lid is painted with white oil paint on the bottom and silver paint on top.

The ceiling is fixed with a clamping structure made up of four 10mm planks fastened with screws. Plank dimensions (in mm):

- 362 on 35 – 2 details;

- 382 of 35 – 2 details.

For installation in blocks during the wandering, a base is made of two beams, 70 mm thick, 120 mm wide and 1 840 mm long. Such a bottom is attached to concrete racks driven into the ground. The common lid is knocked out of 15mm boards. The finished frame is sheathed with tin with a bend around the perimeter.

Cover dimensions (in mm):

- 1 – length;

- 420 – width;

- 70 – height.

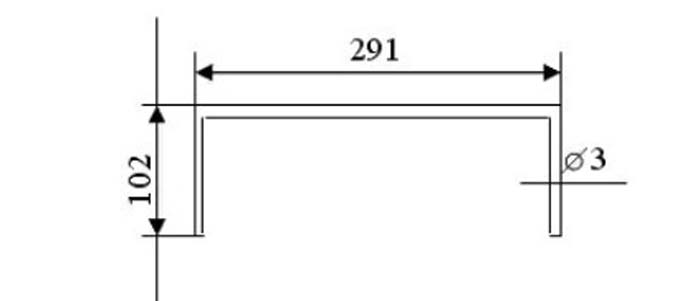

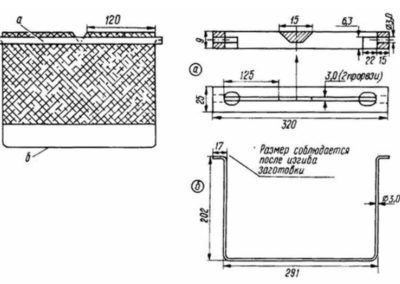

The frame has an original design – it has no side strips and a bottom bar. Around the perimeter in the shape of the letter “P” is installed a black 3-millimeter wire 730 mm long. It is fixed on the upper bar in 3-mm holes specially cut at the ends.

The top bar is made of beech or cherry planks. Its dimensions (in mm):

- 320 – length;

- 25 – width;

- 9 – thickness.

To install foundation on a bar, two cuts are made 100 by 3 mm.

Alpine hive blueprints:

Domestic modernization – Khomich

A small change in the design of Delon was made by our compatriot from the Penza region, Vladimir Khomich, who actively recommends this system to local beekeepers.

The 108th frame alpine hive is known in Russia as Khomich’s hive. This beekeeper practices the placement of the Alpines on a mobile platform. Each hive in the summer is assembled from 10-12 body sections, containing eight honeycomb frames.

However, the dimensions of the case have changed – instead of 215 mm in height, 108-mm sections are made, in which the so-called Khomich’s wire frames by 102 mm fit.

They are mounted from a pine bar and 3-mm wire 488 mm long, installed U-shaped in the end holes of the bar.

Bar dimensions (in mm):

- 320 – length;

- 25 – width;

- 9 – thickness.

This design of honeycomb frames allows you to inspect two bodies at once from below and from above, without removing the honeycomb.

Dimensions of body parts (in mm):

- 360 on 115 – two details;

- 338 on 115 – two details;

- height 108;

- 12 by 12 – folds.

In the figure: a – walls in front and behind; b – sidewalls.

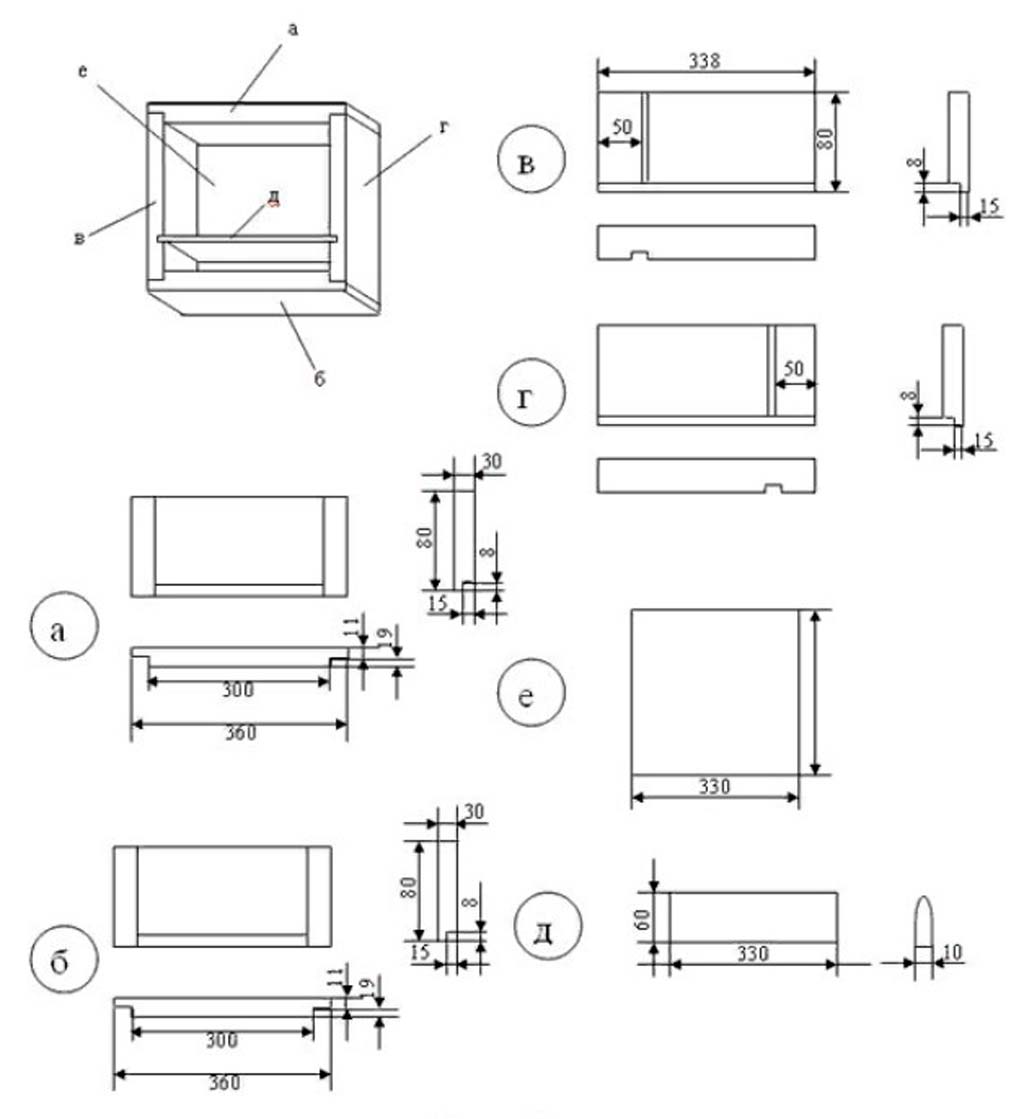

The Delon feeder is complemented by an internal float cut to the dimensions of the compartment with a 15mm hole in the middle. This part allows you to add syrup, excluding its souring, and also serves to prevent the death of bees.

In the figure: a – front wall; b – back wall; в – wall to the left; d – wall on the right; d – partition; e – bottom, mounted from fiberboard.

Separators for honeycomb frames are metal combs installed on the folds.

The bottom has an adjustable tap hole, which increases in the summer by moving the structure forward relative to the bottom. The dimensions of the tap hole in width are 300 mm. The height depends on the season and the shift of the hulls: 12 mm in winter and 20 mm in summer.

The bottom drawing is shown below:

In the figure: a – bottom flap; b – front bar-leg; в – back bar-leg; d – plinth-strapping for the organization of the taphole.

Features of beekeeping

One of the main problems of the migration of bees to the alpine systems is associated with the protracted adaptation of insects to new living conditions. The transition period takes an average of a year, or rather, one summer.

In the hive, you can plant a swarm, layering or a full-fledged bee colony.

If we are talking about a family, it will be easier to restrict the housing in an already used dwelling to the dimensions of an Alpine. Then the Roger Delon or Khomich section is installed directly on the frames. When the bees have rebuilt one body, the second is substituted. And with the beginning of oviposition, the third – in the gap between the first and second sections.

At the final stage of the resettlement, the bottom of the alpine is installed and the old hive is removed. The family continues to live in the same place, but in a house of a different design.

In the fall, the nest is reduced to two hull sections. The foundation drawn by the bees is placed in storage. Nests with a completely open entrance hibernate.

In the spring, with the beginning of active flowering of plants, a third section is installed under the two overwintered sections, fully equipped with land built last year. This technique allows you to induce the uterus to more active worming.

The fourth hull section is placed between the two upper ones when a stable honey flow occurs. Here the bees must rebuild the foundation, after which the fifth section is installed under the uppermost body.

As soon as the fifth body is filled with honeycombs, the sixth is installed – in the cut between the third from the bottom and the fourth section. That is, the uterus is restricted and the swarm instinct is controlled. Brood frames will only be in the three lower sections.

Change of uterus

The replacement of old queens is carried out by the swarm instinct. When changing, you do not need to destroy old females! It is enough to cut the slot on the body, and install the cassette at the very bottom.

Bees stretch queen cells. After that, the body section is separated from the hive and taken to an apiary for mating queens with breeding drones.

The fertilized “queen” is returned to the nest together with the body, in which oviposition begins, by placing it under the upper honey section. A quiet change takes place, and the bee colony is strengthened by brood just before the main flow.

After the end of honey collection, bee colonies live in three buildings until late autumn (the release of the entire brood and the formation of a club).

In conclusion

Roger Delon’s hive system has shown itself well in the Russian climate. This small-sized hive is prized by many beekeepers who are not afraid to experiment. It has been noted that even the most vicious families relocated to the Alps become calmer and more peaceful over time.

In terms of internal dimensions, the Alps are close to the design of Prokopovich and the straw hives of Kullandy. Beekeeping in them is as productive and natural as possible.

But good results are achieved by beekeepers with experience, who have already practiced keeping bees in multi-hull systems, and are ready for financial investments at the first stage of modernization of the apiary using Delon’s technology.