Loungers are a kind of bee houses in which the development of the nest proceeds along a horizontal plane. Unlike risers – multi-body structures, the expansion and build-up of the strength of the bee colonies occurs not by installing the next tier, but by adding new frames horizontally.

The sun beds are considered to be easy to maintain and therefore suitable for novice beekeepers. The main advantage is that the beekeeper is relieved of the constant lifting and moving of weights. When fully loaded, such a hive weighs more than 50 kilograms. However, to pump out the honey, only separate frames have to be lifted.

The only difficulty is problems with weight and dimensions during the wandering. For this reason, nomadic beekeeping farms prefer other, more compact types of hives.

The content of the article

- 1 Basic views

- 2 24-frame with extension

- 3 20-frame with extension

- 3.1 Housing

- 3.2 Bottom

- 3.3 Liner and cover

- 3.4 Letkovye slots

- 3.5 Shop

- 4 Choice of materials

Basic views

Under the name sunbeds, several varieties of the classic design that look like a chest are sold on the market. Beehive lounger is:

- Houses for 20 frames with standard Dadanov frames, measuring 435 by 300 (43,5 wide by 30 cm high). They are readily used by beekeepers from Ukraine.

- Houses for 24 frames with the same dimensions, widespread in Ukraine.

- Houses on an inverted or narrow-high frame, having a width of 300 and a height of 435 mm. They are often called Ukrainian sun loungers.

- Houses for 16 Dadanov frames or Belarusian hives, which are necessarily used with store extensions. According to the technology of keeping bees, they are close to double-hulled or Dadanov hives, and cannot be fully considered as sunbeds.

- Houses for 32 frames are an innovation in beekeeping, better known as the Vladimir beehive. Nowadays, there is no unanimous opinion among professional beekeepers about the benefits and benefits of such a content of honey bees.

In the article we will touch on the classics of sun beds – beehives for 20 and 24 standard frames, which do not cause any controversy and doubt among beekeepers. And houses on a narrow-high frame, as a kind of generally recognized classics, we will consider later.

24-frame with extension

Houses of this type can be used to keep two colonies at once, separated by a blind diaphragm (plywood divider). With abundant honey collection, one magazine can be installed on a standard half-frame (435 x 145 mm). The disadvantages include high weight when fully loaded with honeycombs.

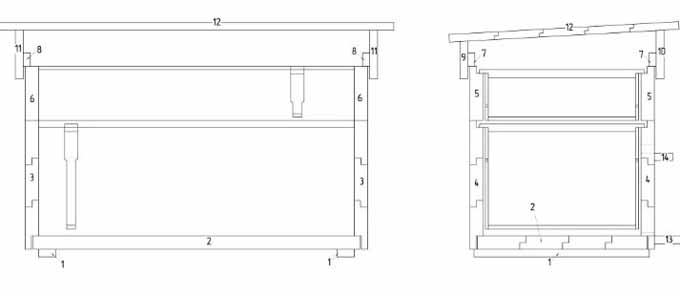

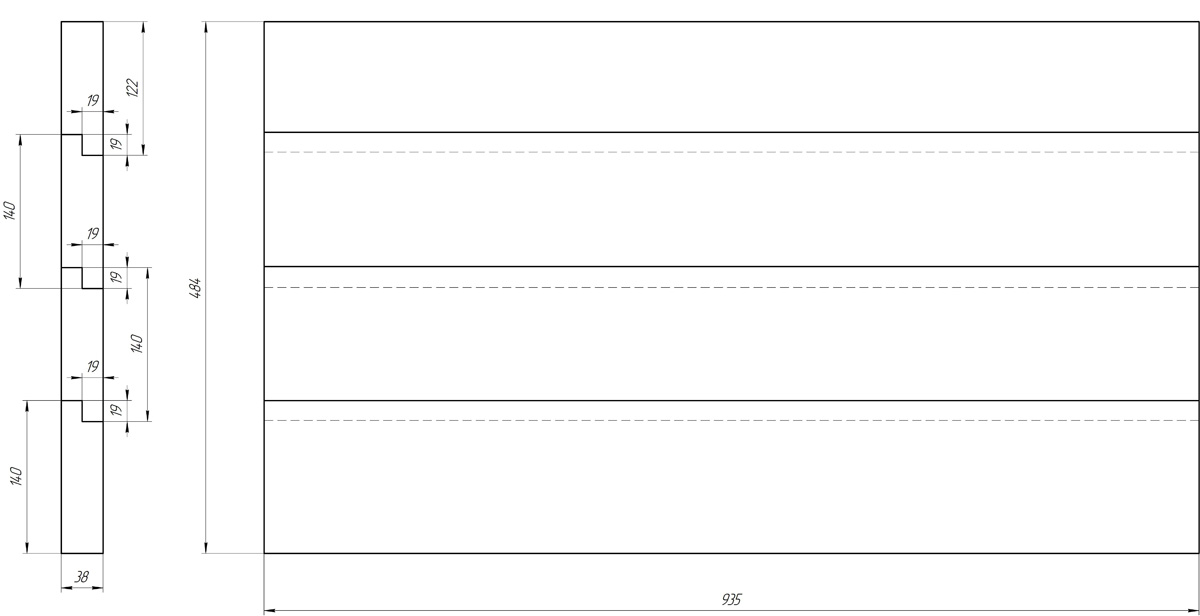

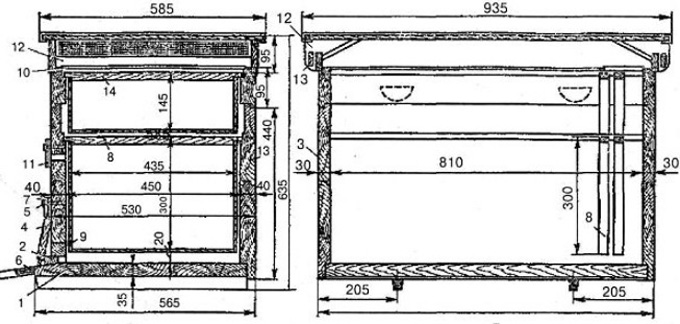

A beehive lounger for 24 frames with your own hands can be assembled according to the following drawings:

Appearance

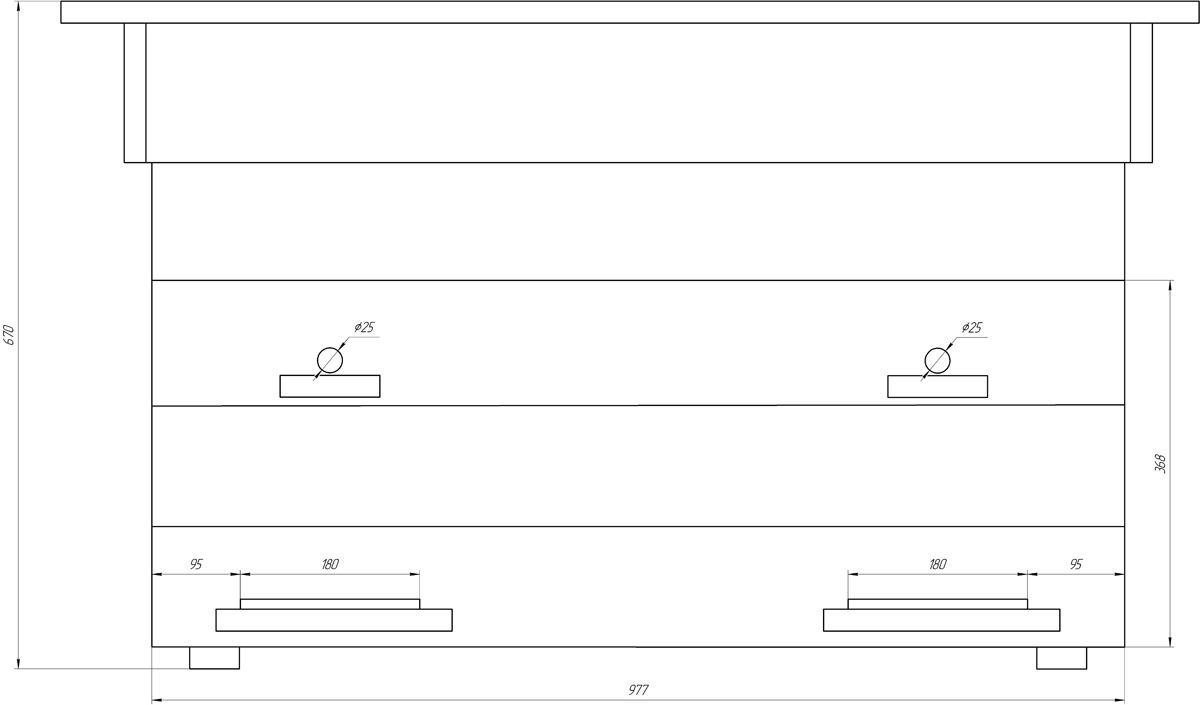

Along the front wall there are two lower entrances in the form of a slot (width 18, height 1 cm) and two upper ones in the form of a hole with a diameter of 2,5 cm. For the convenience of bees’ work, each of the entrances is equipped with boards for arrival.

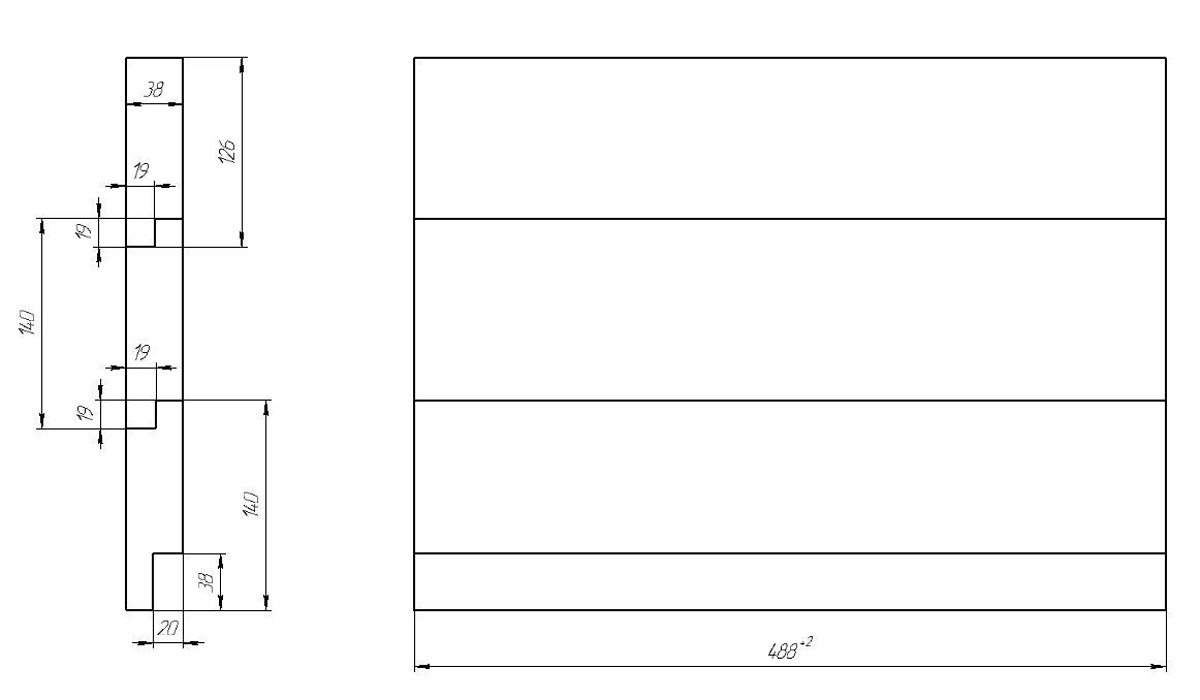

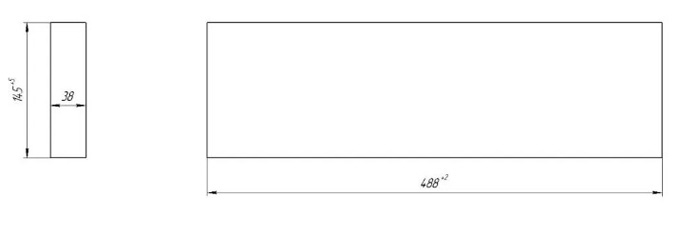

On the side walls, a lower and upper groove is made for installing the bottom and the pressure board at the top. The length of each wall and, accordingly, the width of the finished house is 488 mm.

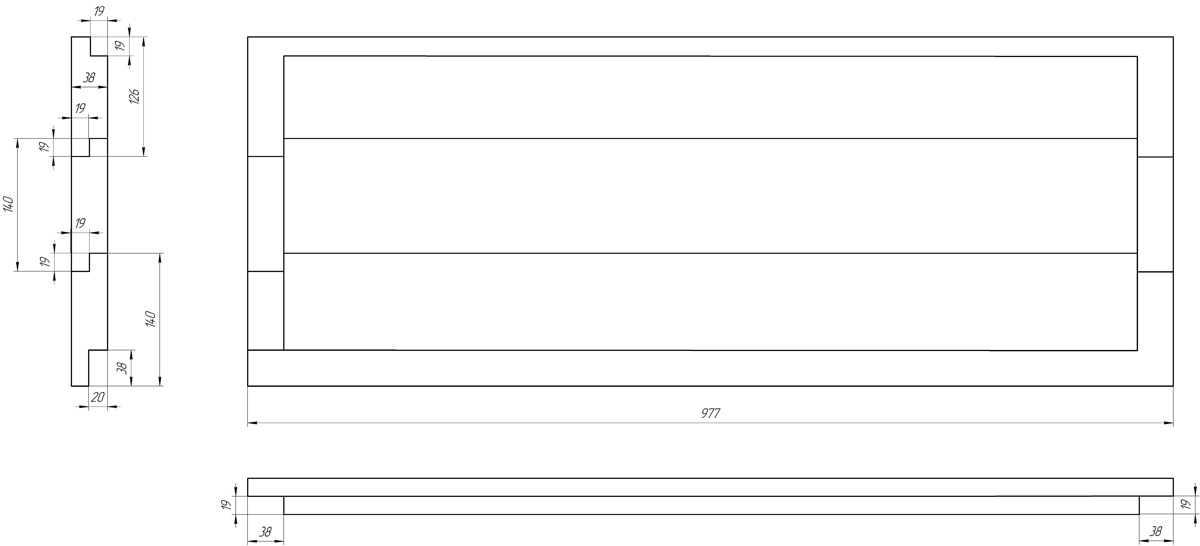

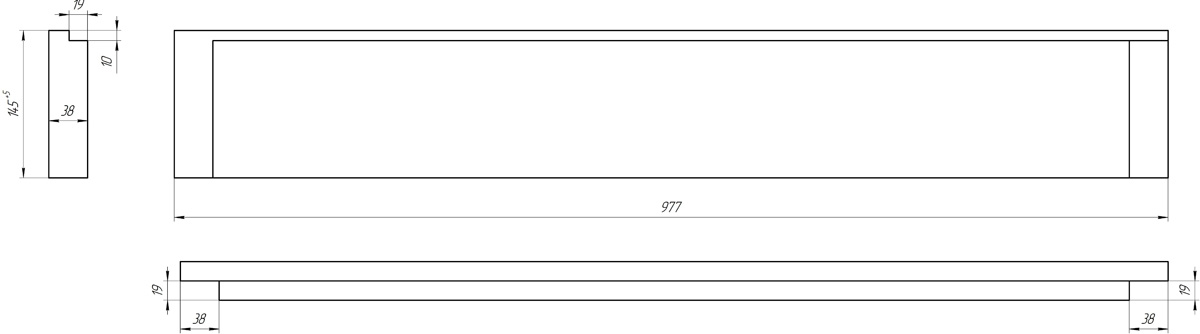

The back and front walls have two folds on the upper inner side: the lower one is used to install frames, and the upper one is used to accommodate ceiling boards. The length of these parts and the entire outside of the house is 977 mm.

The bottom is assembled from several boards and looks like a shield that is firmly attached to the body. All boards are provided with grooves for a tight fit (spliced into a quarter). Floor seams are glued with glue, for example, PVA. The main thing is to protect the house from moisture penetration from below.

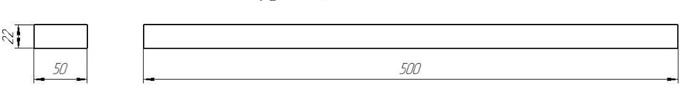

The role of the legs is played by bars 500 in length, 50 in width and 22 mm in height.

The cover is also in the form of a flap attached to the harness and low walls.

Planks no thicker than 2 cm are suitable for strapping (20). This part of the design allows you to put the cover on the body without any additional fasteners.

The cover plate is spliced into a quarter. To protect against moisture, upholstery with tin or galvanized iron is used. Dimensions in finished form: 1,14 long, 66 cm wide and 2,2 cm high. The width of the used boards is 14 cm.

The walls allow you to give the cover a slope of 3,5 degrees, which is necessary for the removal of atmospheric precipitation.

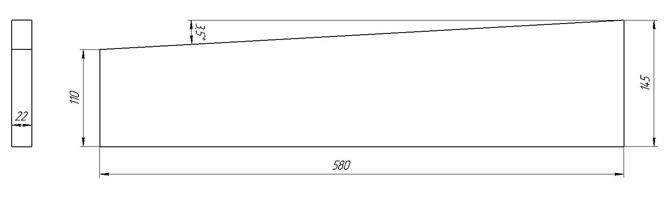

The front and rear parts are equal in length – 988 mm (98,8 cm), but have different heights: at the back it is 11 cm (110), and in the front – 14,5 cm (145). The thickness of the boards used is 2,2 cm (22).

End length 58 cm (580), height: front 14,5 cm (145), back 11 cm (110).

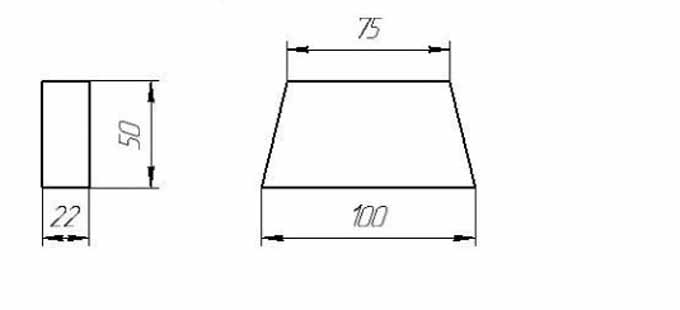

Appearance and drawing of the lower arrival boards:

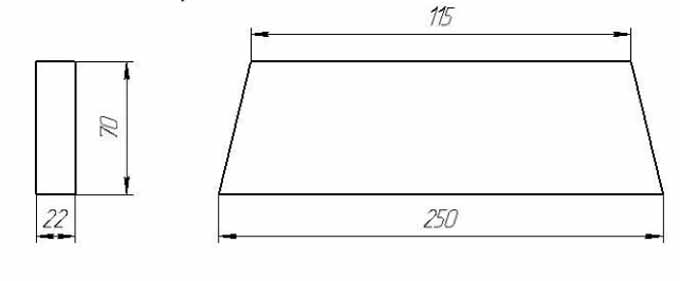

Upper arrival boards:

Note: If desired, their dimensions can be changed! It is not necessary to adhere to the drawing in this case.

If there is a need to use a store extension, it is assembled according to the following drawing (designed for 24 half-frames!):

Folds for honeycomb frames are selected inside the front and rear walls, and there are quarters at the bottom that facilitate installation on the body.

According to the project team ., this is one of the easiest ways to make a sun lounger hive.

20-frame with extension

This hive is assembled according to standard design 3.808-1 and is very popular among beekeepers.

The presence of a diaphragm allows you to keep two bee colonies under one roof at once. In summer, there is a family and layering, and in winter two families, or a family and a nucleus with a spare queen bee.

A store extension with twenty half-frames (435 x 145) greatly facilitates the work of the beekeeper during periods of abundant flow. Of course, you can not use it – it all depends on the preferences of the beekeeper.

The nest is formed of twenty standard (Dadan’s) honeycomb frames with dimensions of 435 x 300 mm.

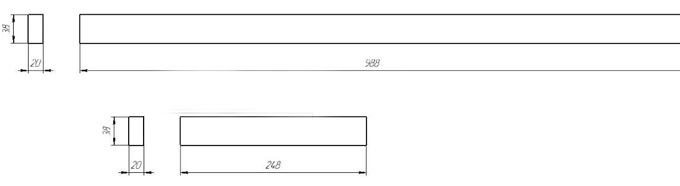

Housing

The body is assembled by gluing into a tongue of 37 mm thick boards. The length of the front and back walls in finished form is 870 (87 cm). The height is different: at the front it is 330 mm, and at the back it is 372 mm.

The sides are also glued into a tongue and have a height of 372 millimeters.

The grooves are made along the outer upper part of the walls and are used to install a store extension. Sizes 10 by 15 mm.

The quarter is located at the bottom of the inner surface of the rear wall and serves to install the bottom. Dimensions 24 x 42 mm.

In the upper part of the structure, folds are selected:

- inside the front and rear walls for hanging honeycomb frames – 10 x 20 mm;

- outside for the installation of the store – 10 by 15 mm.

Bottom

The bottom is assembled from bars and plywood sheets glued into a tongue.

Bottom dimensions (mm / cm):

- length 844 / 84,4;

- width 535 / 53,5;

- thickness 37 / 3,7.

Instead of legs, bars 535 long, 50 wide and 37 mm thick are used. They are nailed at a distance of 18-20,5 cm from the side walls.

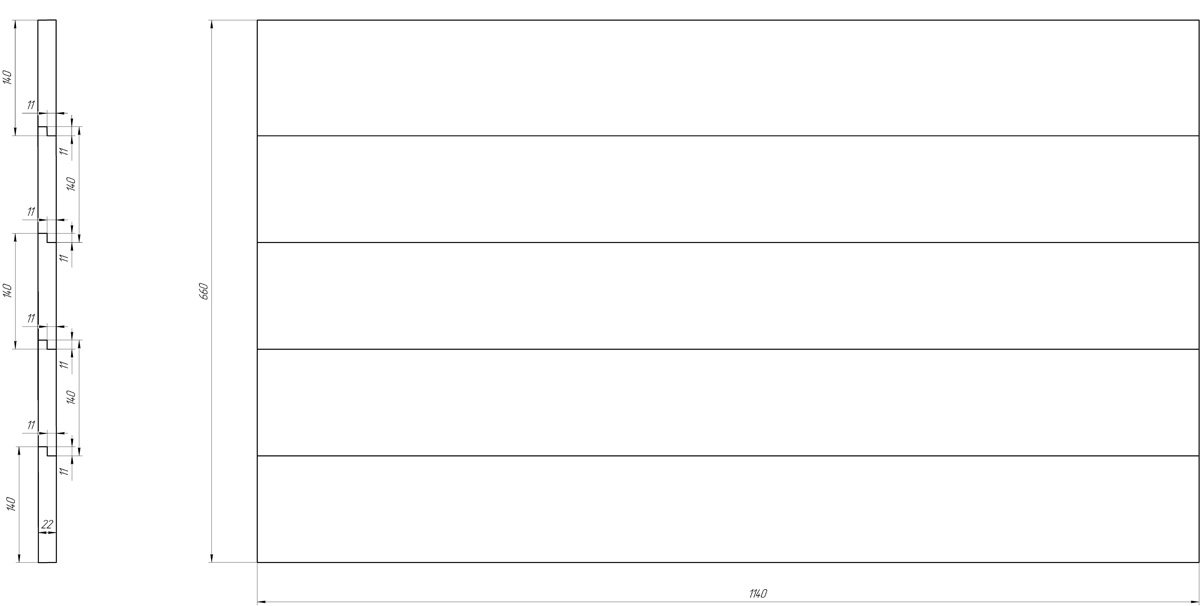

Liner and cover

The roof is a shield attached to the harness. You can assemble it from boards and plywood. Dimensions: 915 x 569 x 15 mm.

The harness is mounted from 56 mm wide boards. The length along the front and rear planes is 915, along the sides – 569 mm. The thickness of all boards is 20 mm. The connection of the harness (frame) is made into a tenon.

Outside, the finished cover is sheathed with a sheet of tin or galvanized iron.

The roof cover is required in three cases:

- if the apiary is located in a climatic zone with severe winters;

- if the hives have to be transported in the summer during the migration;

- if the bees are actively feeding, then feeders are placed above the frames.

It is assembled into a spike from boards 25 mm thick. When finished, it has a length of 870, a width of 524 and a height of 90 mm.

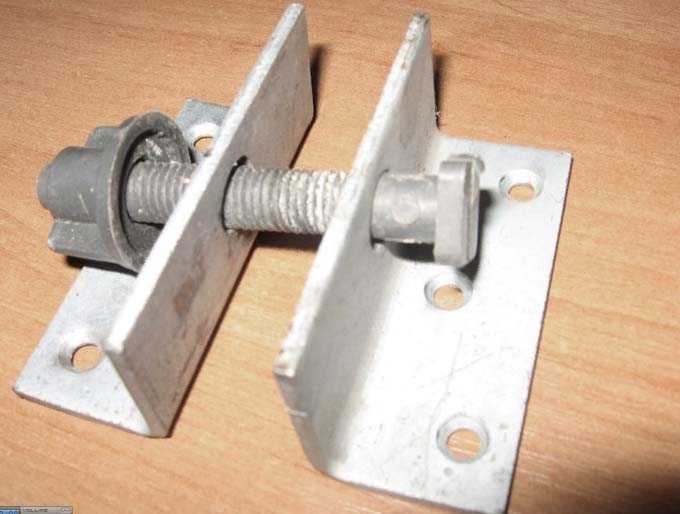

For the strength of the side connections, it is recommended to fix these areas with metal tape!

Letkovye slots

In total, such a bee house should have four entrance holes located on the front wall, which allows simultaneously containing two bee colonies at once:

The lower notch slits are centered relative to the midline of the wall and are made 19 cm apart. Each slot is 25 cm long and 1,2 cm high.

The upper notch slits are made 19,6 cm from the lower edge of the wall. The distance between the notches is 32,2 cm. The length of each slot is 6,8 cm, and the height is 1 cm.

Arrival boards (shelves) must be installed! The size is arbitrary.

Shop

The store top is a box of 3 cm (30 mm) thick planks. In finished form, the store is 870 (87 cm) long and 524 (52,4 cm) wide. The assembly is carried out in a thorn or with nails and glue.

Places for folds (in mm):

- on the inner surface of the upper part of the front and rear – 20 by 11 (for hanging honeycomb frames);

- on the lower part inside – 10 by 24 (to install the store);

- on the lower part inside the sidewalls – 10 to 17 (also for placement on top of the body);

- on all walls at the top outside – 10 by 13 mm (for joining with a sub-roof or cover).

Choice of materials

The following boards are suitable for work:

- of willow;

- from linden;

- from cedar;

- from fir;

- from spruce;

- from non-resinous pine;

- from poplar.

The boards must be free from defects. According to GOST, their thickness is 37-40 mm. The admissible humidity is not more than 15 percent! Fine-toothed saws are used for sawing.

Finished high-quality parts do not have chips, roughness, hairiness – everything is carefully planed. Rotten knots are removed and the holes are closed with plugs on waterproof glue.

The best connection is in tongue and groove. If nails are used, their size is selected depending on the thickness of the lumber. To strengthen the structure, metal strips are stuffed in the corners from the outside.

Permissible errors (discrepancy with the drawings) – no more than 0,5-1 mm.

A well-assembled bee house lasts at least 30-50 years, subject to the technology and the right choice of lumber.

You can read about how to make custom sun loungers here:

Vladimirsky lounger

Lounger Lazutin