The design of the hive bottom has undergone many changes. Our grandfathers have always used a deaf integral bottom. A little later, it was replaced by the detachable, and then the mesh bottom of the hive.

The idea of replacing reliable boards with metal mesh can lead to beekeepers brought up on classical standards into real confusion. Information about hive boxes with a net cannot be found in old beekeeping manuals, but the topic is actively discussed on professional forums. Let’s try and we will understand this difficult issue.

The content of the article

- 1 New construction bottom

- 2 When and where it is used

- 3 Year-round application

- 4 Arguments for”

- 5 Arguments against”

- 6 Structural features

- 7 Self assembly

New construction bottom

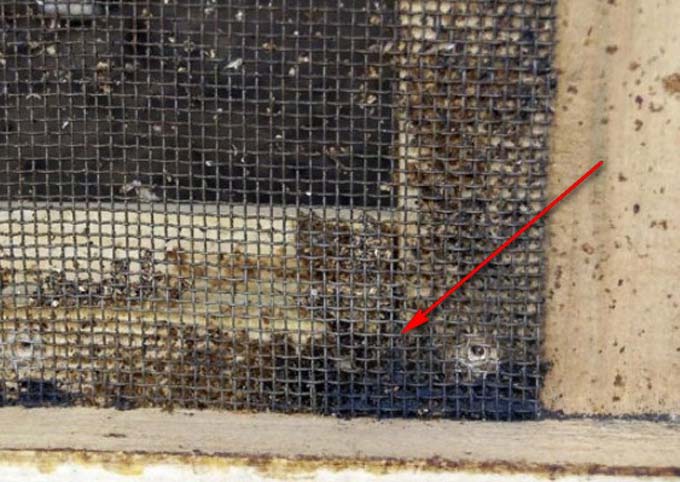

The mesh bottom for a multi-body hive is by no means a novelty abroad. It looks something like this (there are different assembly options):

In our country, such a bottom has become widespread thanks to small-format hive systems, which in many respects go against the standard once established in Russia, and for this reason did not displace the classics familiar to us – Dadans and the Langstroth-Ruth system hives.

To read:

MFP hives (small format)

Also, the bottom of the hive with a mesh is typical for the most modern models assembled from expanded polystyrene or polyurethane foam. These materials require enhanced ventilation of the bee nest, as they themselves do not “breathe”. The idea came from Finnish bee box manufacturers that specialize in the listed polymers.

When and where it is used

Bees hibernate very well on nets without a bottom in those regions where constant temperature fluctuations occur – for example, there is a small plus during the day, and the thermometer drops below zero at night.

The bee club breathes, giving off condensation. It rises to the ceiling and then turns into frost on the walls. An increase in temperature above freezing promotes the melting of frost – water flows down to the bottom to freeze there later.

Frequent thaws lead to real problems! It happens that the lower blocks of the frames are trapped by the ice that has accumulated at the bottom during the winter. In such a nest, it is very damp, mold is visible on the frames and walls.

Mesh hive trays solve the problem of high humidity, because water leaves the bee housing in a timely manner and it remains dry.

It should be emphasized here that bees do not heat the entire hive space as a whole. What is easy to verify by putting a thermometer on the bottom – the indicators will be almost equal to the street ones. Insects retain heat only inside the club – the installation of a net does not prevent them from withstanding even 30-degree frosts. The main thing is that there are no drafts.

The bottom is covered only at the moment the spring brood appears, when it is important to preserve the microclimate. As soon as the first worker bees appear on the entrance, actively ventilating the dwelling, the bottom valve can be immediately abandoned.

Year-round application

Beekeepers who have tried the new technique often use year-round keeping their pets on a bottom net. At the same time, the ceiling can be either deaf or with slots for air outlet (but without drafts!).

The enclosures are installed on a special stand, reminiscent of a magazine with a folding back wall. To give rigidity to such a high bottom, two jumpers are stuffed from below. A frame with an attached mesh is laid on top.

For the winter, an empty store or housing is additionally installed under the nest (to protect the bee club from the wind). If the winters are too cold, a thin layer of dry moss can be spread over the netting.

A space of 1-1,2 cm is left between the upper bars of the honeycomb frames. A rare fabric such as burlap or homespun track is spread over the ceiling. You can put additional insulation on it in the form of moss or dried fern. Thin slats are placed under the cover so that moisture does not accumulate in the insulating layer and on the fabric.

Dead water is not removed during wintering – it does not interfere with the bees. All the slots are covered to prevent them from being swept up by snow, drafts and not to attract birds. They are opened only at the end of winter.

After the spring flyby, the empty hull or magazine is removed from the hive, and the net is covered from below. The distance from the bottom edge of the frames to the mesh overlap is standard – 20 mm. With the onset of steady heat, the net for the hive bottoms opens completely.

If the mesh insert is not used year-round, the valve is half closed at the end of the season, immediately after the drones are driven out. From October to the end of February it is filmed. And from the beginning of March until the gardens bloom, the plywood is returned to its place and pushed in completely. Summer, like winter, is spent by bees on an open net.

Arguments for”

There are a lot of advantages of a net installed on the bottom – here are the main ones:

- Varroa mites leave the nesting area during drug treatment;

- through such a bottom, you can easily use a smoke cannon (treat with sublimation of a medicinal preparation) – you do not need to climb into the entrances, disturbing the bees;

- in the spring there will be no dampness, mold, fermented honey in the hives;

- in winter, there is no need to clean the entrances from the accumulated undermoor at the bottom;

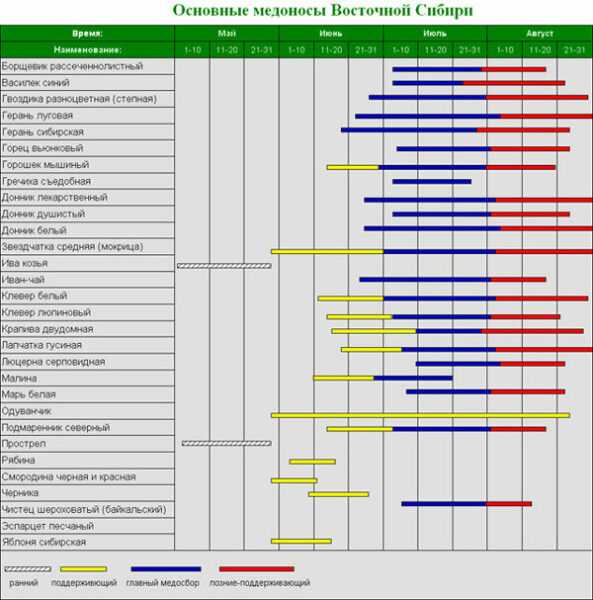

- in the summer, the family will not need workers to ventilate the house – everyone will fly away for nectar and pollen;

- bees will not steam up during the wandering;

- families can be kept closed without problems when the fields are treated with chemicals.

Arguments against”

The disadvantages of such a bottom cannot be considered a big disadvantage. Rather, these are just its features that will have to be reckoned with during operation:

- installing a mesh makes the construction of the entire hive more expensive;

- crumbs of wax and pollen particles freely fall down through the mesh layer, which attracts wax moths – if pests start in the garbage, the mesh will have to be disassembled in the spring, clean the harness and disinfect everything;

- when feeding bee colonies in winter, thieves are activated – the open bottom does not drown out the appetizing smell, and if a drop of syrup accidentally falls on the net, an attack cannot be avoided;

- if the bottom is completely mesh, it will not be possible to use pegs when installing the hives – it is imperative to fill the crossbars (this complicates the nomadic journey);

- blind bottoms are less overall, because high (deep) bottom structures are usually made for nets.

Structural features

The bottom design can be different. Each option has its own little peculiarities.

Mesh installed on the whole bottom, serves as the basis for the design. A body section is placed on the folds in its strapping.

The difficulties of operation include the accumulation of debris under the hive, inconvenience when installing on stakes, as well as the need to use an additional plywood pallet gate.

If debris on the ground attracts ants, moths or other insects, the soil should be turned over with a shovel and tied with dry lime.

Bottom with small mesh window in the form of a square in the center or a strip along one wall (as an option, stripes around the entire perimeter) looks more reliable in harsh climates. However, such a design is quickly clogged with submergence – bees, if overlooked by the owner, can suffocate.

Deep bottom – the most convenient option, allowing you to install the mesh inside the structure and provide grooves for the plywood gate valve here. In this design, a rear door is made to the full width of the hive to extract the dead. Height from 10 to 15 centimeters.

Self assembly

The mesh on the bottom of the hive should be installed only metal! Any other material can be easily damaged by the insects themselves or by various enemies of the apiary.

Moreover, the smaller the cell, the more comfortable it is inside the bee’s nest. A section of 1 by 1 or 1,5 by 1,5 mm completely solves the problem with wind blowing! Of course, a size of 2-3 mm can be used, but the fresh air flow will be sharper.

The bottom valve can be made from any suitable material. Most often, plywood or plastic is used.

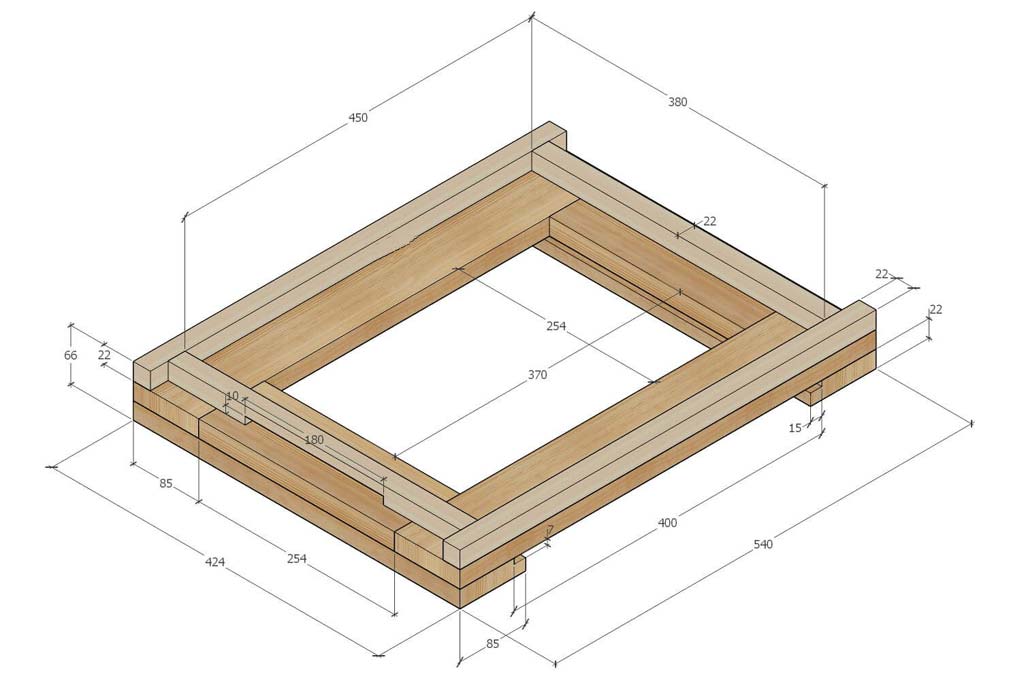

You can make the bottom of the hive with a mesh following the example of the drawing for a horned hive:

Craftsmen offer many assembly variations, depending on the type of construction and dimensions of the bee housing.

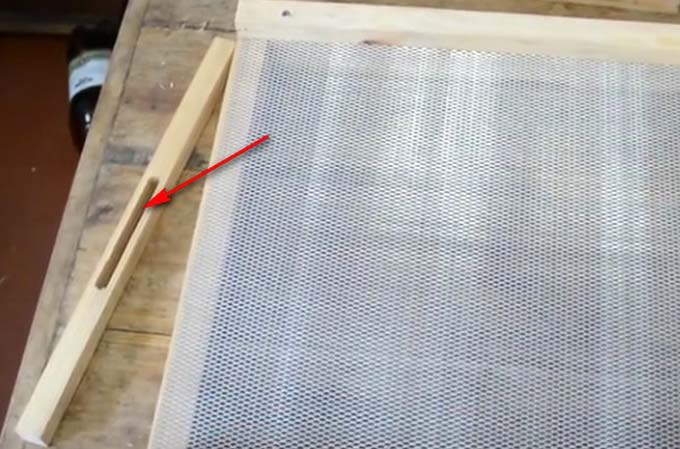

The simplest option is presented below.:

Wooden blanks are pre-boiled in paraffin to prevent rotting during operation! Then the base is mounted from the bars of a suitable size. The assembly is done in a quarter with two screws for each fastener.

A piece of stainless wicker mesh with a mesh of 1,5 to 2 mm, or galvanized expanded metal with a pitch of 2,0 to 8,0 mm, is laid on top.

It is believed that the larger the cell size, the higher the likelihood of removing ticks during processing – they immediately fall to the ground. But keep in mind – cells of 3 mm freely pass wax moth during storage of sushi!

The mesh element is pressed along the perimeter with blocks and fixed with self-tapping screws.

In the front part of the harness, a slot is made for the tap hole.

In conclusion, I would like to note that additional ventilation through the bottom prevents late emergence of brood in the fall. In the spring, bees start rearing young animals a little later than in ordinary hives, but they always have time to gain strength for the honey harvest. Dead wood extracted from a hive equipped with a net will always be dry, like all parts inside the dwelling. The health of families is perfectly demonstrated by the plywood valve – there is no mold on it, wax chips and debris are absolutely dry in spring.