The beehive lounger offered by Andrey Yakimov is known on the market as Vladimirsky. Being a follower of natural beekeeping, actively promoted by Fedor Lazutin, Andrey strove to improve the design of the classic lounger. That made it possible to keep these honey insects with minimal interference in their lives.

The content of the article

- 1 design Features

- 2 Completion and varieties

- 3 Self assembly

- 3.1 Framework

- 3.2 Body dimensions

- 3.3 Materials and Tools

- 3.4 Frame and body assembly

- 3.5 Letki

design Features

By its design, the Vladimirsky hive lounger is a bee house, in which the development of the nest occurs in the horizontal plane due to the installation of frames with dry land and foundation.

Accordingly, it is devoid of the most perceptible disadvantage for the beekeeper – a lot of weight. When working with bee colonies, there is no need to lift and move heavy bodies. It is this feature that many beekeepers take into account when choosing hives.

The second positive point is the increased internal volume of the house. 32 honeycomb frames are installed in the hive, which have a non-standard size – 435 by 460 mm. In width, this corresponds to the Dadan frame, which has been successfully used in sun loungers of a suitable size. And the honeycomb frames are similar in height to the frames from the Lazutin hive.

The area of the Vladimir frame is 1,5 times larger than the standard Dadanov frame and 2 times larger than the Rut one. But at the same time, it has a significant drawback – it will not work to pump out honey in an ordinary honey extractor.

This problem is easily solved. You can make homemade prefabricated structures – combine the Dadan frame and half-frame in a vertical plane using bolts. When evacuating, they are easily disassembled into two parts, both of which are placed in the honey extractor.

The third feature of the Vladimir hive is the increased wall thickness. You can choose a size from 8 to 12 centimeters.

The roof is made in three versions:

- flat;

- single-slope;

- gable.

Completion and varieties

The author of the design offers three types of hives:

For 11 200 rubles you can purchase budget option from plywoodframe assembled and insulated with foam. Weighs 35 kilograms. The lid is hinged and covered with galvanized iron. The set includes 32 honeycomb frames. The disadvantages of beekeepers include the material used. Plywood in harsh winters confuses many, and foam cannot be classified as environmentally friendly materials. The galvanizing on the lid is considered to be a source of additional noise during heavy rain that disturbs the bees.

For 14 rubles sold eco-beehive option, assembled by the frame method from lining and insulated with linen wool. Weighs 50 kilograms. The roof is covered with glass insulation. The lid is fixed to the body by means of hinges as standard. Wall thickness 8-10 cm. The kit includes 32 frames.

“Eco-Lux” sold at a price of 16 rubles. Such a bee house is assembled from lining and insulated with Swang moss. The roof is hinged, covered with glass insulation. Wall thickness 500-10 cm. The hive is equipped with a standard number of frames. Weighs 12 kilograms.

Self assembly

All dimensions and drawings of this lounger are kept secret for obvious commercial reasons, but some points for self-assembly can still be clarified.

Framework

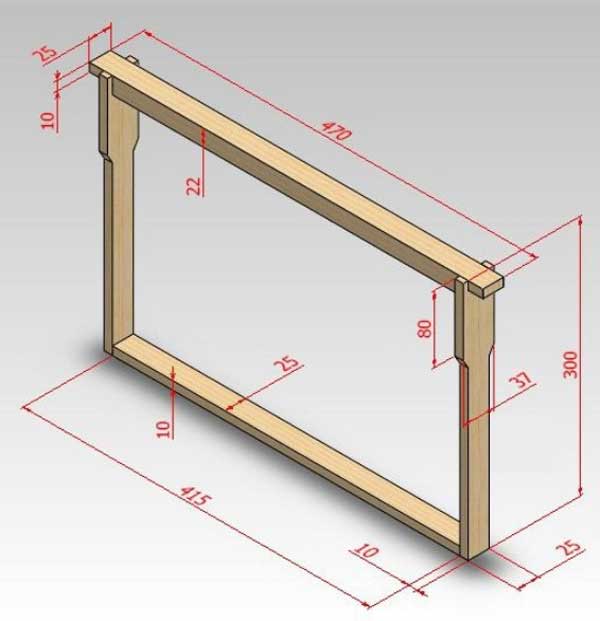

The drawing of the Dadanov frame is taken as a basis:

It is extended by side bars to the required 460 millimeters. To be assembled with small studs and a stapler with staples (number 18). Additional reinforcement of the joints is carried out using PVA glue. The best material for work is lime boards with a moisture content of no more than 15%.

The side strips are necessarily cut out on the machine. This is the hardest part of the job. The rest of the details can be made by hand using an electric jigsaw.

Self-production will save 2 rubles on each hive. It is at this price that Andrey Yakimov sells sets of honeycomb frames.

Body dimensions

Inside the case has the following dimensions (in mm):

- 500 in height;

- 450 wide;

- 1 in length.

External dimensions depend on the thickness of the walls, bottom and roof. And also from the shape of the lid.

Wood shavings and dry moss are used as insulation. In a relatively warm climate, you can get by with an air gap in the inter-wall space – this is an excellent heat insulator. And inside the bees themselves will close all cracks with propolis, getting rid of drafts.

Materials and Tools

Soft breeds are selected for work: willow, linden, poplar, fir, alder, aspen, pine, spruce. Such wood is lightweight, retains heat well, does not warp under the influence of moisture and sunlight.

Of the tools you will need (indicative list):

- mechanical and electrical stapler for assembling honeycomb frames;

- miter and circular saw;

- woodworking machine;

- electric planer, jigsaw, milling cutter;

- drill for 1 watts;

- hammers and screwdrivers;

- two screwdrivers (one for pre-drilling holes, the second for screwing in a screw – this technology will speed up the assembly);

- screws and self-tapping screws (they are the easiest to screw in and, if necessary, unscrew);

- professional glue for assembling hives with D-4 marking, for example, Titebond brand.

Moreover, glue is not needed to seal absolutely all joints. The bees themselves are able to close what they think are unnecessary cracks with the help of propolis.

Frame and body assembly

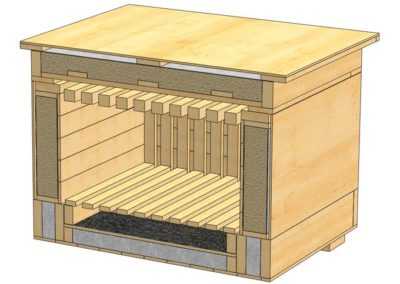

Vladimirsky beehive do-it-yourself lounger must be mounted using frame technology.

At the first stage, 6 shields are made (walls, flat lid, bottom), which are stuffed onto the finished frame. For the assembly of the walls, four bars 450 mm long are used.

Dimensions:

- section of bars 50 by 50 mm;

- inner walls made of boards (20 mm);

- external – from boards (30 mm).

When finished, each flap is 10 centimeters thick. It can be increased if desired. However, do not forget that the weight of the hive will become noticeably larger.

It is better to attach the lid to the body with hinges so that it folds back and does not interfere with the beekeeper’s work.

Letki

Letkovye holes are made along the front wall. Their diameter is 50 mm. For work, crowns are used that allow you to drill a hole 100 mm deep – then you do not have to bother with drilling both sides of the front panel (shield) in turn.

Accommodation:

- 45 mm from the bottom of the wall (calculated from the bottom cut to the center of the holes);

- 130 mm from the corners (for extreme entrances);

- 188 mm between adjacent entrances (considered in the center of the holes).

In total, six entrances are made, which are then covered with latches that rotate along the central axis.

If you have the appropriate experience in work, it takes an average of 12 hours (one and a half working days) to assemble one product. And for beginners, it will be useful to first purchase a ready-made hive as a sample. And already focusing on him, make the rest of the houses for your apiary.