Fitting the frames with wire and then installing the foundation is still one of the most time-consuming operations in beekeeping practice. The quality of the honeycomb rebuilt by bees largely depends on how correctly the frame was stretched. And the mistakes made lead to the breakage and deformation of the honeycombs during the operation of the frames.

Various homemade devices will help to significantly facilitate the tightening process. We will talk about their application today.

The content of the article

- 1 Tensioning machine

- 2 How to avoid unauthorized unwinding of the coil

- 3 How to avoid sagging

- 4 Unconventional way of pulling

Tensioning machine

It is usually recommended to pull the wire until it rings like a string when you touch it. Of course, this advice is good. But in practice it is extremely difficult to apply it.

As soon as the beekeeper overdoes it, the attachment breaks. It is even worse if, during operation, under the weight of honeycombs filled with honey, the wire begins to cut through the layers of wood – the foundation sags and easily deforms during the summer heat.

The machine, which helps to work correctly with the wire, is assembled from a wooden plank measuring 3 by 3 and 64 centimeters long. A hole for the wedge is punched on one side, as shown in the figure.

The wire is pulled through all holes. Then the frame is placed in the machine and clamped from the side with a wedge – while the side plates bend slightly. After that, the base for the foundation is stretched, without making any special efforts, and the ends are fixed. The wedge is removed from the machine. Due to the flexibility of the wood, all four wire rows are pulled evenly.

This work does not require much effort. The machine is easily handled by women and teenagers.

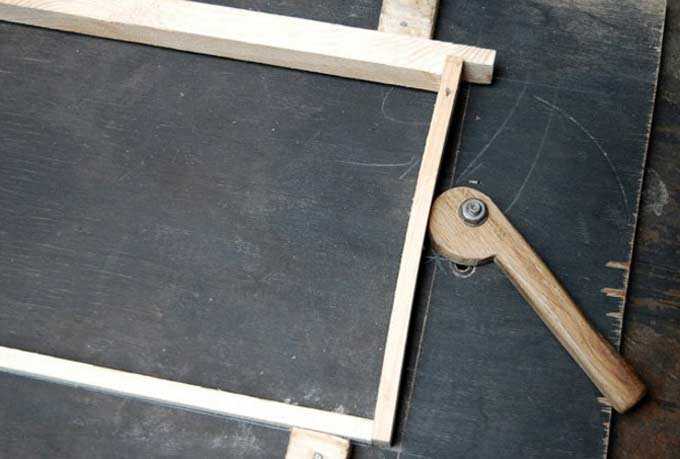

There are several options for such a device. All of them imply the use of some kind of lever that temporarily deforms the side strips of the frame. For example, it might look like this:

The homemade machine is mounted directly on the tabletop.

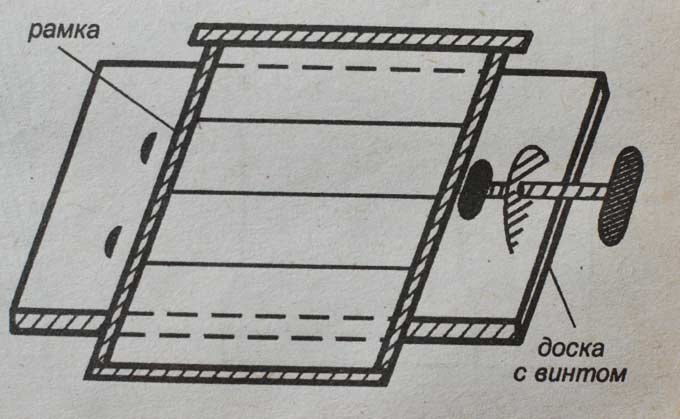

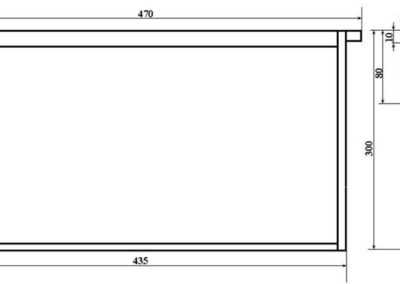

Or another variation is the use of a separate board 3 thick, 47 long and 22 centimeters wide.

At one end, two metal or wooden posts 3 centimeters high are driven in. They will serve as a stop for the side rails. And at the other end, a bracket is mounted, in which there is a hole for a screw (a bolt with a nut or a screw part from an old meat grinder with a washer at the end).

A frame with a wire threaded into the holes is inserted between the posts and the screw, the latter is clamped a little, achieving deformation of the side plates. The wire frame is then easily pulled and secured in the lower left corner. Then the screw is released – the frame straightens and provides high-quality tension.

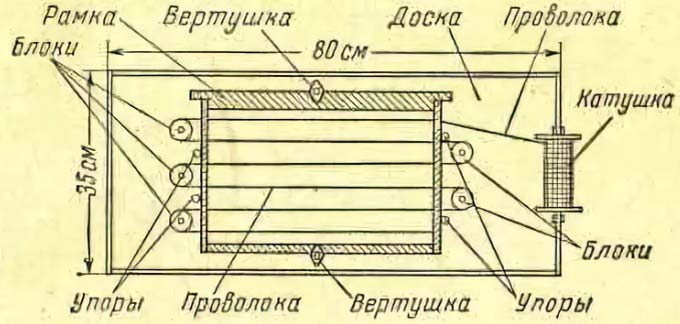

And here is an example of using a homemade machine with blocks:

This option requires more parts and extreme precision in installation.

How to avoid unauthorized unwinding of the coil

Wire is a capricious material that tends to unwind during operation. This significantly reduces labor productivity.

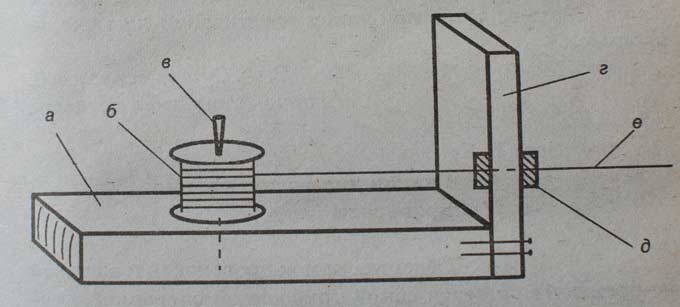

F.G. Zotin from the Gorky Region advises building such a simple device:

- On a board (a) 50 mm thick and 60 centimeters long, a coil (b) is nailed with a weaving nail (c). It is necessary to retreat from the edge by 10-15 centimeters.

- On the opposite side of the board, a plank (g) is stuffed with a length of 15, a width of 2 and a thickness of 1 centimeter. A puncture is made in it with a strong awl. In this case, you should be guided by the installed coil. The hole should be in the middle of the bar and at the same time at half the height of the coil (e).

- If felt (e) is nailed on both sides of the strip, it will be possible to clean the wire from the factory oily grease.

Another option for this type of device is the use of a pressure plate made of steel sheet or three-layer plywood.

The width of the plate is selected strictly according to the dimensions of the coil! And the dimensions of this machine are arbitrary.

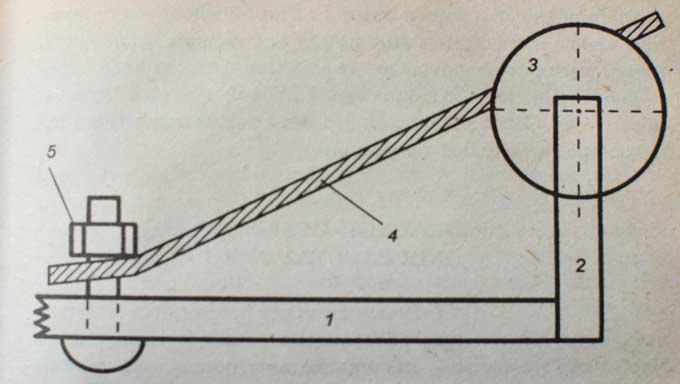

The base is made of a strip, to which the bracket (2) is attached, and the coil (3) is installed on it. At the other end of this base is a bolt and nut (5) used to adjust the amount of pressure on the plate during operation.

How to avoid sagging

During operation, the wire can cut into the frame strips. This is not so much a tension error, but a natural process – under the influence of gravity, the wood wears out.

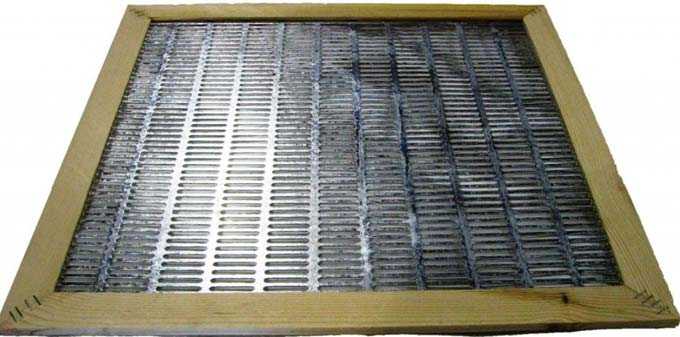

To prevent damage to the side strips, you can insert shoe buttons into the holes. But since this process is quite laborious, you can take ordinary pushpins – it is easier and faster to work with them. The buttons are pinned directly next to the holes drilled for the wire, so that the edges of each cap are at a distance of 1-2 mm from the hole.

It is not necessary to install buttons in the places where the ends of the wire base are fixed! And so that the wire easily enters the holes and is easier to stretch, it is pre-rubbed with wax.

During operation, the buttons prevent the penetration of the wire into the wood. In a well-taut position, the frames can be stored for a long time – the wire does not weaken over time.

Unconventional way of pulling

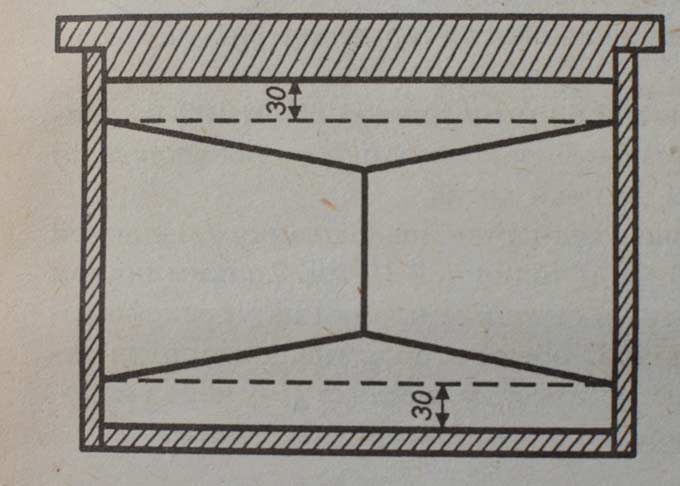

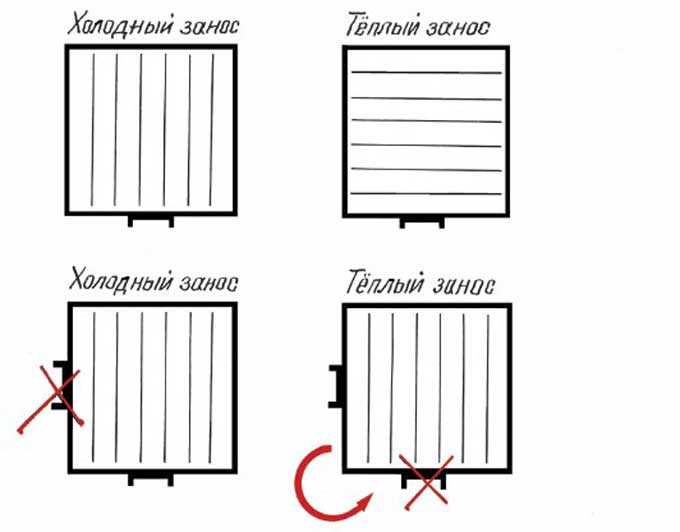

S.F. Sugatov from the Gorno-Altai region recommends using not four-row, but two-row wire tension.

This technique allows you to avoid overtightening during secondary navachivanie. The honeycomb is held firmly – there are no breaks and accidental deformation.

Two wire threads are installed in a horizontal plane at a distance of 3 cm from the upper and lower bars.

In the middle, they are tied with wire, which gives greater rigidity to the base.

In temperate climates, vertical tension can be used – from the top to the bottom bar. This is what we do team ., and so far we have no complaints about this method. The bars are more rigid than the side bars. They hold up to tension well without being reinforced with push pins. The honeycomb does not deform in the heat. The only drawback is that in this case all work is done manually, without using a machine.

Additional Information:

Simple do-it-yourself apiary equipment – an article about homemade knives and chisels

How to impose frames – using effective homemade products

Choose the tensioning method that suits you best. And it can only be determined in practice. We hope that the designs of homemade apiaries proposed here will help you in this difficult matter. And don’t forget to use cotton gloves. Take care of your hands.