Every beekeeper knows what rolls are for foundation. The manufacturing method is also known. But not everyone has the necessary equipment and is forced to purchase foundation in specialized stores. The production process is easy to make a profitable business, helping your own bees with this important element for their activities and selling some of the products.

What are foundation rolls

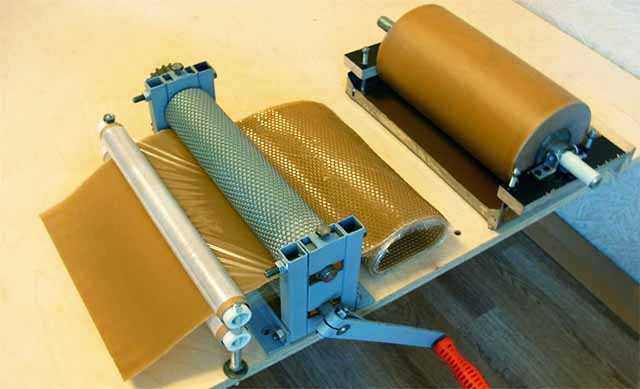

In the production area, foundation is made on automatic lines. At home, in the field apiaries, everything is much easier. Rolls for making foundation is much more convenient and practical than a special press. To make foundation, it is enough to pass a wax sheet through them.

Types

There are several types of similar equipment on the modern market:

- engraved

- smooth;

- hand held;

- with electric drive.

The difference in the shape of the surface of the rolls is that the engraved ones already have a characteristic pattern. Rolling the plate, a blank in the form of hexagons, resembling a honeycomb, appears on its surface. After that, it remains only to shape, fix it on the frame and place it in the hives. Then the bees will independently pull the combs, which are used to collect honey and brood.

Smooth rollers are only used to roll the wax mass onto the sheets. The surface is smooth, without a pattern. Therefore, it is important to have both machines.

Production of foundation using rollers

This is a profitable activity not only as caring for your wards. There are statistics showing that in one season the owner winds waxes on hand rollers for an amount of about 10 thousand dollars, without being distracted from the main occupation. Therefore, it is advantageous to use rolls for the production of foundation.

Foundation making is not difficult. Each sheet takes less than a minute. Prepare two rollers and a clean wax, free of stains and debris. The technology is a bit like twisting laundry on old washing machines:

- grease the rollers with a mild soapy solution so that the wax does not stick;

- add a little soda to the finished solution;

- make tape on smooth rollers or use store purchased;

- move the finished tape or wax sheets onto an engraved roller and pass through it;

- the finished foundation is stored in a dark, cool place.

If you do not want to use a soapy solution, you can use another product consisting of water, glycerin and liquid honey.

Home-made foundation does not differ from the factory one. But, since the production uses water (wetting solution), it gets into the sheets. Therefore, the finished sheets are in small stacks or 5-6 pieces. Store in a cool, well-ventilated area. And only after a few days they chop off the piles for long-term storage.

Experienced beekeepers say that the longer the foundation is stored in the warehouse, the better it becomes. It is impractical to use the newly produced one. This is another of the reasons that should force you to produce a pen and produce an important product yourself and have a valuable beekeeping product in sufficient quantity.

Technology features

There is nothing special about the preparation of foundation on the rolls. The most important thing is that the wax is clean, free of impurities. On a dirty foundation, the bee may start pulling drone combs.

The wax quickly heats up the rollers, and the sheets begin to stick. To prevent this from happening, it is necessary to cover with ice and do not forget to lubricate with soapy water. Wax does not like heat. Better to keep it within 15 degrees.

How to make rolls for making foundation

The price of rollers in the retail network is high. Self-production of a machine for the production of foundation is a rather laborious process. But given the cost of the finished equipment, it is desirable to master it.

Tools and materials

It is necessary to prepare the main components:

- two waves;

- two gears;

- bolts for adjustment;

- base for fastening the finished machine;

- work tool.

Assembling the apparatus

The work is carried out in several stages:

- install the bed;

- a U-profile is suitable for a vertical base;

- use an additional chain for the mechanism;

- install the chain on the sprockets;

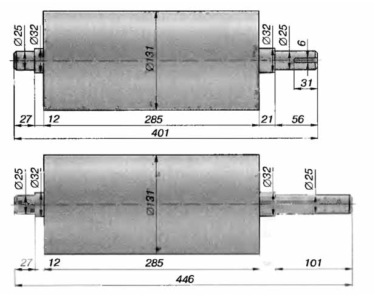

- make rolls using hardened steel or food grade aluminum cylinders;

- cover with a silicone matrix that you can make yourself;

- adjust the size of the gap;

- fix on a prepared basis.

To give the matrix strength, add a small amount of building ceramics to it.

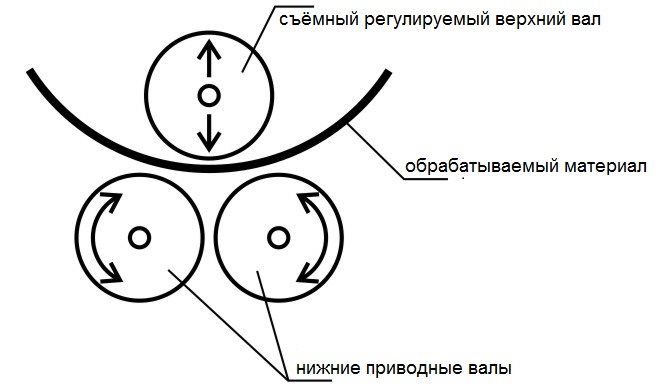

Some owners prefer to order the production of rollers from a milling machine with sufficient experience. Each cell should be perfectly the same. The lower shaft must be fixed on bearings, the upper one moves by inertia of the first one. On finished rollers produce at least 10 kg. foundation for an hour.

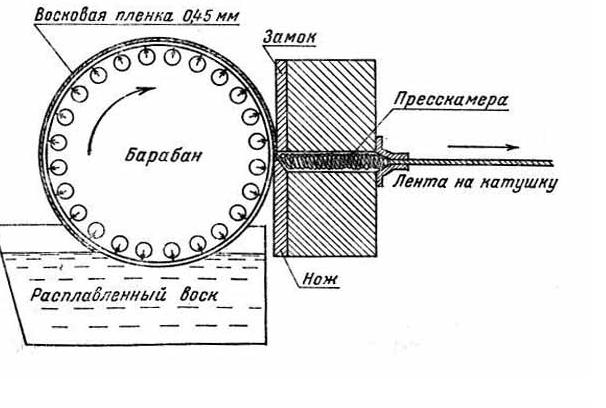

The presence of the tray marked on the drawing is optional. But it is much easier to work with her presence. It contains roller treatment fluid or melted wax. With its presence, there is no need to constantly manually lubricate the rollers. The same tray is used to make wax sheets.

It is filled with clean wax. A sheet of plywood or glass is abundantly moistened with water. It is dipped in molten wax several times. After hardening, it comes off easily and the plate is ready for rolling. The melted wax can be poured into molds that look a bit like a baking sheet. The material frozen in them is also used.

But many beekeepers note that preparing semi-finished sheets is a painstaking and time-consuming business. Therefore, if there are no smooth rollers, and there is experience with engraving, then it is better to make a second machine.

Manufacturing errors

During the manufacture of a home machine, some errors occur. It is important to take them into account when starting independent work;

- cracks on the shafts;

- reduced clearance due to incorrect adjustment;

- compression of the main parts, mechanisms.

Take these indications into account in order to exclude the poor performance of the machine.

Home Rollers Benefits

A handmade model made by yourself is painstaking but profitable. Savings and added value in business. With little experience, every beekeeper can try to make such a machine. After work, it is important to check the condition of the shafts, wash and dry them. Lubricate bearings regularly. In addition, it is important to observe the storage conditions of the equipment so that it lasts a long time.

Foundation making is an effective method that allows the production of sufficient material for the insects to function properly. Do not leave bees without this material while he is looking for where to get a factory one. Small size of the machine and no need to connect to the mains. He is present with the beekeeper on his way to the melliferous places. And they are much easier to use than the press.

It is important to make sure that children or strangers do not try to pass paper, pieces of rags through the rollers. This cannot be done.