For any gardener working on the bed is a pretty hard job. Most often, such agricultural operations as planting potatoes, hilling them, weeding potato bushes and subsequent harvesting are done by themselves. However, many have adapted for these purposes to use a motor block for potatoes, thereby reducing their labor and time spent in the garden.

Using a walk-behind tractor for growing potatoes

Preparatory phase

At the initial At the stage of soil preparation, a motor-block device for cultivating the earth is used using a plow with cutters. In proper cultivation, when preparing soil for planting potatoes, settings for plowing are of no small importance:

- plowing and cutting of the earth is carried out at a depth of no more than the size of the spade of the bayonet of the middle shovel, and this is 10-12cm,

- the passage of the cultivator in width should be in the range from 0.5 to 0.6 m in the row spacing,

- when plowing hard soil and tops, the depth of the furrow harrowing increases to 20-25 cm.

Most often, gardeners use a double-handed plow to plant land before planting potatoes ug, mounted on a walk-behind device.

Requirements

- to dig the soil and go through the land during cultivation and loosening so that one cutter of the plow cuts the soil that has not yet been excavated and the other walked along the dug track, thereby improving the quality of the preparatory work being done,

- to reduce the number of turns during digging, the land stretches along the longest side,

- at the turning points motor-blocking device back when plowing the soil, the soil is leveled manually by rake.

E There is a model of motoblock mechanisms for processing, which make it possible to dig up the earth in a circular manner. Among these are MTZ brand cultivators. Their movement begins in the middle of the land and is carried out along a spiral path. MTZs are convenient in that the operator has the opportunity to plow the ground, walking when plowing next to the walk-behind tractor on unpaved soil.

Semi-automated method

Motoblock with okuchnik

Planting potatoes with the motoblock can be done in a semi-automated way with the okuchnik. This method of sowing involves carrying out work on a small landing area and requires the use of a hiller attached to a motor-block device.

The purpose of the semi-automated planting method is to raise soil, create a furrow and form earthen ridges on the sides.

Types of hills

Okuchniki for semi-automated planting can be used different:

- ordinary lister, which have an adjustable or fixed working width, outwardly they look like knives, consisting of two bent plates connected together in front and diverging at the back,

- disk.

Fixed Hubs

Hubs with a fixed grip Willow and not quite successful for planting potatoes with a walk-behind tractor. Their working grip is about 20-30 cm, which is not enough for a potato.

Adjustable hullers

An okuchnik for planting potatoes with an adjustable width is more popular among gardeners, as it makes it possible to build the size of the land grab, setting the preferred row spacing. We must not forget that its design requires the use of a stronger motor-block mechanism weighing from 30 kg and a power of 4 liters or more. The disadvantages of its use include high fuel consumption and reduced productivity, because part of the soil from the crest crumbles again into the furrows.

Disk hillers

The disk is more productive design of all of the above, but it is not cheap . Externally, the disk hiller looks like a flat platform of beams with attached rotating disks during movement.With such a device, you can adjust the inter-disk distance and the angle of inclination, it is less energy-consuming and more convenient to use, it is able to form smooth earthen ridges of sufficient height.

Landing technology

Regardless of what kind of hiller you prefer when planting potatoes, the technology includes several operations:

- the hinged structure is initially mounted on the walk-behind device for hilling, lug wheels are attached, if the hiller allows, the minimum setting is width of the soil,

- furrows are formed, in which we manually sow potatoes,

- the lug wheels are replaced with simple rubberized grips, in adjustable designs the working width is set to the maximum,

- using a motor-block device, furrows with planted potatoes are covered with soil.

Automated method

With a potato planter, the process runs faster

With the automated method of planting potatoes, all the opera AI techniques are carried out, and it involves the use intended for this curtain potato.The standard potato planter includes a number of structural elements:

- furrow section, which is responsible for the formation of ruts in the ground,

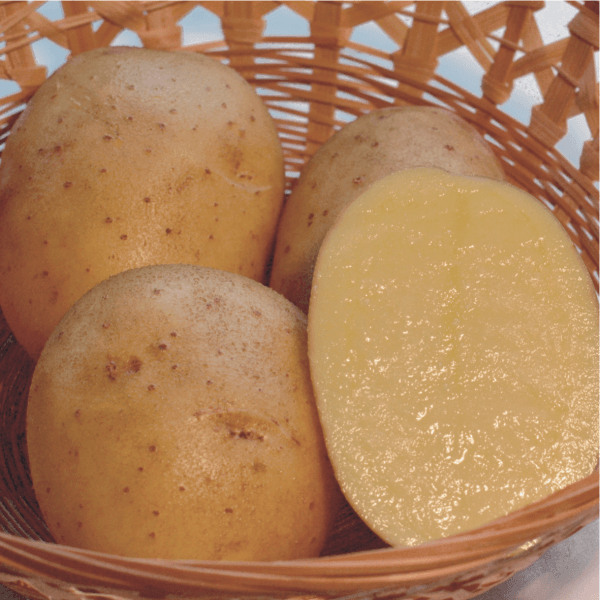

- bins, where the seed is put,

- laying mechanism,

- a disk hiller used to backfill the track with planted potatoes.

An automated method of planting potatoes with a motoblock mechanism equipped with a potato planter makes it possible to cope with process in just one pass, saving time, fuel and effort.

Landing under yh

In addition to the semi-automated and automated methods of planting potatoes, you can use the method of planting under the plow.

In the absence of the ability to purchase expensive devices, many gardeners use a simple planting of potatoes with a walk-behind tractor plow. It differs from the above in that:

- as an attachment, a homemade plow with cutters is often used,

- forms a furrow, where the seed potatoes are immediately folded with their hands,

- after a turn, a new ridge is formed, falling asleep at the same time.

For the convenience of this method of planting under a plow, gardeners sometimes mark the cultivated area with a rope, pulling it at the required distance. This is done in order to withstand the same distance between the furrows.

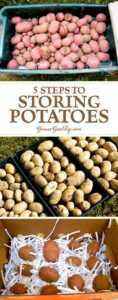

Care and harvesting

The motoblock device acts as a reliable assistant not only when planting, but also in the process of caring for potato bushes and harvesting the grown crop.

Hilling

The best way to develop a potato crop is the hilling process, which involves dusting the bushes with loose soil. Gardeners do such events 2-3 times a season:

- initially with a bush height of 15cm, this stage occurs in the second half of May,

- secondary hilling by technique is carried out at a bush height 20-25cm, or 2 weeks after the initial procedure,

- for the third time, many do the hilling in 14 days to add soil higher.

If you follow the experienced authors of the recommendations, the use of a walk-behind tractor is advisable at the initial stage, so that in subsequent times the mowed bushes will be mowed and not damaged eat potato tubers.

Rules for hilling by walk-behind tractor

Hilling by walk-behind tractor involves a number of measures:

- setting up a hiller and adjusting the angle of rotation and depth of immersion in the ground,

- replacing the lug wheels with rubberized ones,

- the location of the walk-behind tractor with a nozzle in the center between the rows,

- moving at no speed.

Harvesting

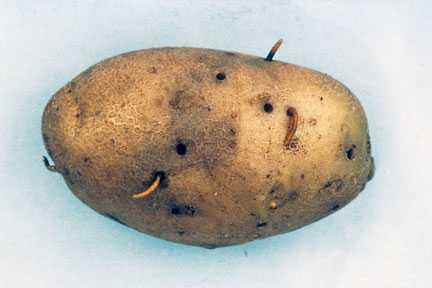

Digging potato tubers during harvesting with a walk-behind tractor is carried out using a potato digger specially designed for digging when replacing an earthenware box that is not suitable for this purpose. It looks like a nibbler, but its solid surface has been replaced by a rod grate.

A fan-shaped potato digger is convenient because the digger goes deeper into the ground, raises the soil along with root crops that remain on the rods, and the earth crumbles.

Harvesting efficiency if excavated potatoes tillers, it depends on the depth of immersion potato digger and can be up to 90%. Ogorodniki adapted to experience walking tractor to dig potatoes by omitting structure not deeper place of root crops location. Digging through a row allows you to save potato tubers from falling under the walk-behind tractor, preventing them from mechanical damage by walk-behind wheels.